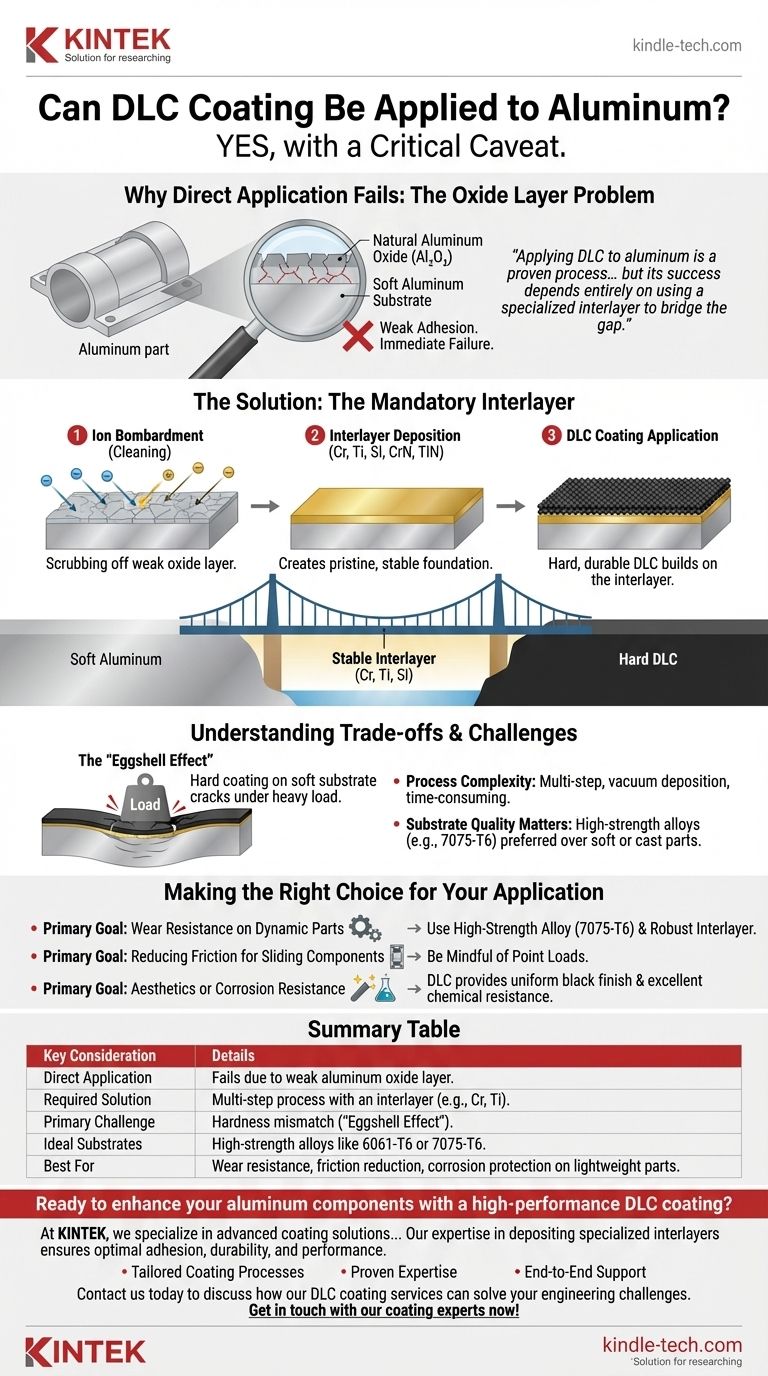

Yes, but with a critical caveat. Applying Diamond-Like Carbon (DLC) coating directly to an aluminum surface will result in immediate failure. The process is absolutely possible and frequently done, but it requires a specialized, multi-step approach involving one or more intermediate layers to ensure the coating properly adheres and performs as expected.

Applying DLC to aluminum is a proven process for achieving high performance on lightweight parts, but its success depends entirely on using a specialized interlayer to bridge the gap between the soft aluminum substrate and the hard ceramic coating.

Why Direct Application Fails: The Oxide Layer Problem

To understand why an interlayer is necessary, we first need to look at the fundamental nature of an aluminum surface.

Aluminum's Natural Barrier

Virtually all aluminum surfaces are covered by a thin, invisible layer of aluminum oxide (Al₂O₃). This layer forms almost instantly when bare aluminum is exposed to the air.

While this oxide layer provides some corrosion resistance, it is a poor foundation for a high-performance coating. It's relatively soft and has weak adhesion to the underlying aluminum metal.

The Adhesion Challenge

Attempting to deposit a hard, dense DLC film directly onto this fragile oxide layer is like trying to build a solid brick wall on a foundation of loose sand.

The internal stresses within the DLC coating, combined with any external mechanical load, will cause the weak oxide layer to fracture. This results in the DLC flaking or peeling off with minimal effort.

The Solution: The Mandatory Interlayer

The key to successfully coating aluminum is to first create a stable, well-adhered foundation upon which the DLC can be built. This is the job of the interlayer.

How It Works: A Bridge Between Materials

The process takes place in a vacuum chamber. First, the aluminum part is subjected to ion bombardment (a type of micro-sandblasting with charged particles) to scrub the weak oxide layer off the surface.

Immediately after this cleaning, a metallic interlayer is deposited. This layer, often chromium (Cr) or titanium (Ti), bonds tenaciously to the fresh aluminum. This new layer now serves as a pristine, stable, and highly adhesive foundation for the final DLC coating.

Common Interlayer Materials

Several materials are used as interlayers, often in combination to create a graded transition from the soft substrate to the hard coating.

Common choices include elemental metals like Chromium (Cr), Titanium (Ti), or Silicon (Si), and sometimes ceramic compounds like Chromium Nitride (CrN) or Titanium Nitride (TiN).

Understanding the Trade-offs and Limitations

While effective, applying DLC to aluminum is not without its challenges. Understanding the trade-offs is crucial for a successful application.

The "Eggshell Effect"

The most significant challenge is the extreme hardness mismatch between the aluminum substrate and the DLC coating. DLC is exceptionally hard, while aluminum is very soft.

If a sharp or heavy load is applied to the surface, the soft aluminum can deform underneath the coating. The hard DLC film cannot flex with this deformation and will crack, much like an eggshell. The interlayer helps, but it cannot fully eliminate this fundamental issue.

Process Complexity and Cost

This is a multi-step vacuum deposition process. Preparing the aluminum, depositing the interlayer, and then depositing the DLC adds complexity and time, making it more expensive than coating a simpler substrate like tool steel.

Substrate Quality Matters

The quality of the base material is critical. High-strength aluminum alloys like 6061-T6 or 7075-T6 provide a much better foundation than softer alloys or porous cast aluminum parts. A smooth, well-prepared surface finish is also essential for optimal adhesion.

Making the Right Choice for Your Application

To decide if this process is right for you, consider your primary goal.

- If your primary focus is wear resistance on dynamic parts: Ensure the aluminum alloy is a high-strength grade (like 7075) and that the interlayer is robust enough to support the DLC under operational loads.

- If your primary focus is reducing friction for sliding components: DLC is an excellent choice for aluminum parts, but be mindful that significant point loads can still cause substrate deformation and coating failure.

- If your primary focus is aesthetics or corrosion resistance: DLC provides a uniform black finish and excellent chemical resistance, making it a viable but premium option compared to anodizing or painting.

By understanding the critical role of the interlayer, you can successfully leverage the unique benefits of DLC on lightweight aluminum components.

Summary Table:

| Key Consideration | Details |

|---|---|

| Direct Application | Fails due to weak aluminum oxide layer |

| Required Solution | Multi-step process with an interlayer (e.g., Cr, Ti) |

| Primary Challenge | Hardness mismatch ('Eggshell Effect') |

| Ideal Substrates | High-strength alloys like 6061-T6 or 7075-T6 |

| Best For | Wear resistance, friction reduction, and corrosion protection on lightweight parts |

Ready to enhance your aluminum components with a high-performance DLC coating?

At KINTEK, we specialize in advanced coating solutions for laboratory and industrial applications. Our expertise in depositing specialized interlayers ensures that your DLC-coated aluminum parts achieve optimal adhesion, durability, and performance—whether for wear resistance, reduced friction, or superior corrosion protection.

We provide:

- Tailored Coating Processes: Customized interlayer strategies for your specific aluminum alloy and application needs.

- Proven Expertise: Technical knowledge to mitigate challenges like the 'eggshell effect' and ensure long-lasting results.

- End-to-End Support: From substrate preparation to final coating, we guarantee a flawless finish for your lightweight components.

Contact us today to discuss how our DLC coating services can solve your engineering challenges and elevate your product's performance.

Get in touch with our coating experts now!

Visual Guide

Related Products

- Aluminum Foil Current Collector for Lithium Battery

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Warm Isostatic Press for Solid State Battery Research

People Also Ask

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- What is the plasma generation in PECVD? The Core Technology for Low-Temperature Thin Films

- What is the base material of DLC coating? Unlocking the Power of Engineered Carbon Films

- What are the advantages of DLC coating? Achieve Superior Hardness, Low Friction & Corrosion Resistance

- What are the advantages of plasma deposition? Achieve Superior, Durable Coatings for Complex Parts

- Why can plasma-enhanced cvd PECVD operate at relatively lower temperature as compared to lpcvd? Unlock Low-Temp Thin Film Deposition

- How is PECVD different from CVD? Unlock Low-Temperature Thin Film Deposition

- Does DLC coating rust? Unlock Superior Corrosion and Wear Resistance