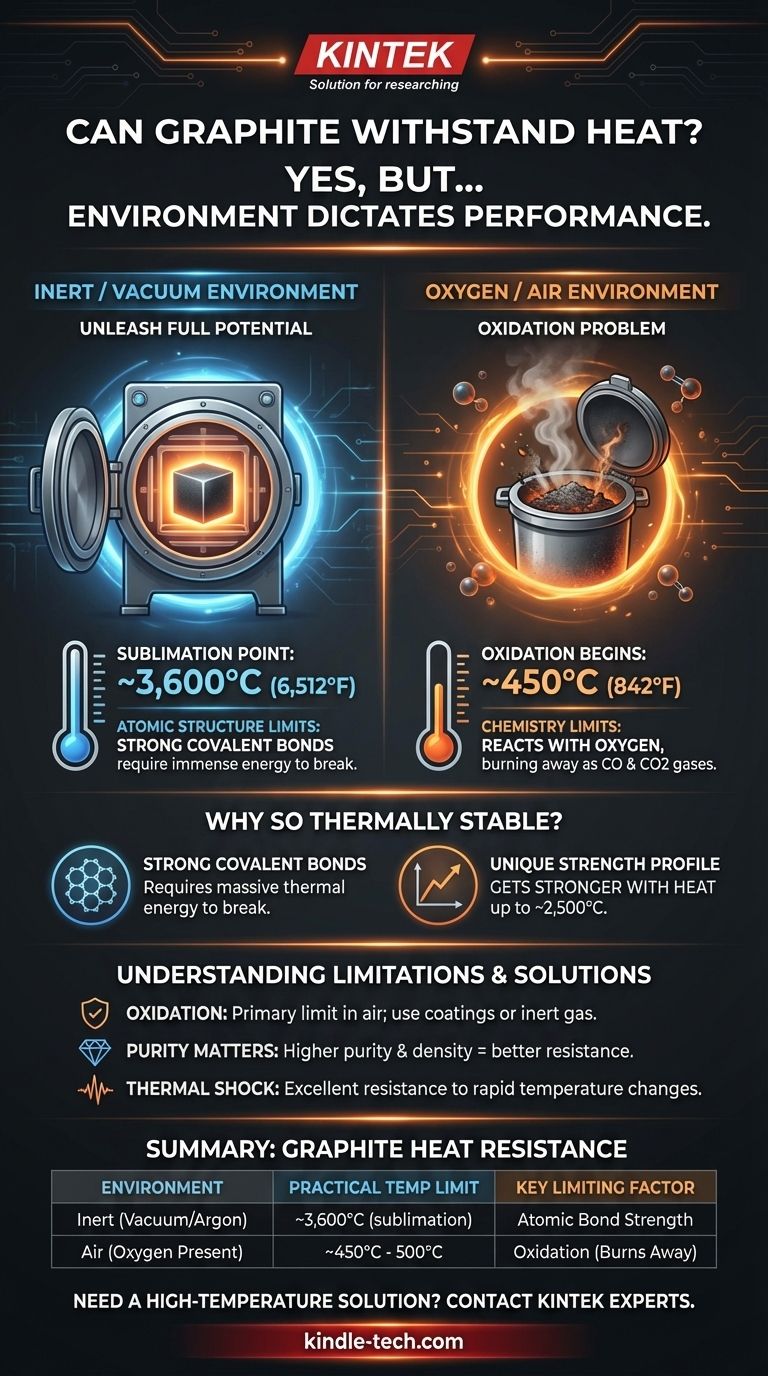

Yes, graphite's ability to withstand heat is extraordinary; in fact, it is one of the most heat-resistant materials known to science. It does not melt at atmospheric pressure but instead sublimates (turns from a solid directly into a gas) at an exceptionally high temperature of around 3,600°C (6,512°F). However, this incredible performance has one critical caveat: it is only achievable in a vacuum or an inert (oxygen-free) atmosphere.

While graphite has one of the highest sublimation points of any material, its practical heat resistance in most real-world applications is not defined by melting, but by its reaction with oxygen, which begins to degrade the material at a much lower temperature of around 450°C (842°F).

The Two Realities of Graphite's Heat Resistance

To use graphite effectively, you must understand the two distinct environments that dictate its performance. Its heat resistance is not a single number but a function of its surroundings.

In an Inert Environment (No Oxygen)

In a vacuum or an atmosphere filled with an inert gas like argon or nitrogen, graphite displays its full potential.

Without oxygen to react with, the only thing limiting graphite is its own atomic structure. It takes an immense amount of energy—heat—to break the powerful bonds holding its carbon atoms together. This is why its sublimation point is so high, making it a premier choice for furnace components, heating elements, and crucibles used in vacuum or controlled-atmosphere furnaces.

In the Presence of Oxygen (Air)

In the presence of air, the story is completely different. The practical temperature limit of graphite drops dramatically.

This is not a failure of melting but of chemistry. A process called oxidation occurs where the carbon atoms in the graphite react with oxygen in the air. This reaction, which creates carbon monoxide (CO) and carbon dioxide (CO2) gas, essentially causes the graphite to burn away slowly, losing mass and structural integrity. This process begins around 450°C to 500°C (842°F to 932°F).

Why Is Graphite So Thermally Stable?

Graphite's remarkable thermal properties are a direct result of its atomic structure and the bonds that hold it together.

The Strength of Covalent Bonds

Within each layer of graphite (a single layer is known as graphene), carbon atoms are arranged in a honeycomb lattice. They are held together by extremely strong covalent bonds. These bonds are highly stable and require a massive amount of thermal energy to vibrate them to the point of breaking, which is why the material can remain solid at such high temperatures.

A Unique Strength Profile

Unlike metals, which weaken as they get hotter, high-purity graphite exhibits a unique and highly valuable trait: it gets stronger with increasing temperature. Its tensile strength can nearly double from its room temperature value as it heats up, peaking around 2,500°C (4,532°F) before it begins to weaken as it approaches its sublimation point.

Understanding the Trade-offs and Limitations

While powerful, graphite is not a universal solution. Understanding its limitations is critical for successful application.

The Oxidation Problem is Paramount

For any application in an open-air environment, oxidation is the single most important limiting factor. Above 500°C, the rate of material loss will accelerate, making unprotected graphite unsuitable for long-term, high-temperature use in air. Specialized coatings or using antioxidant-treated grades of graphite can raise this limit, but it remains a primary design constraint.

The Impact of Purity and Density

Not all graphite is the same. The material comes in many grades, from lower-cost extruded graphite to high-purity, fine-grain isostatic graphite. Higher-purity and higher-density graphite generally offer better resistance to oxidation and greater mechanical strength at temperature. Lower-purity grades contain contaminants that can act as catalysts, accelerating oxidation at lower temperatures.

Excellent Thermal Shock Resistance

One of graphite's major advantages over ceramics is its exceptional resistance to thermal shock. Because of its high thermal conductivity and low thermal expansion, it can withstand extremely rapid changes in temperature without cracking. This makes it ideal for applications like casting molds and crucibles that are subject to fast heating and cooling cycles.

Making the Right Choice for Your Application

To select the right material and approach, you must first define your operating environment.

- If your primary focus is reaching maximum temperatures in a vacuum or inert gas: Graphite is an elite choice, suitable for use in applications like furnace susceptors and fixtures up to and beyond 3,000°C.

- If your primary focus is high-temperature use in open air: Your practical limit is the oxidation temperature (~450°C), and you must design for it or invest in specialized antioxidant treatments or protective coatings.

- If your primary focus is structural stability and thermal cycling: Graphite's unique ability to get stronger with heat and resist thermal shock makes it superior to many ceramics for applications like continuous casting dies, molds, and rocket nozzles.

Understanding the critical difference between graphite's theoretical heat limit and its practical performance in air is the key to leveraging its remarkable properties successfully.

Summary Table:

| Environment | Practical Temperature Limit | Key Limiting Factor |

|---|---|---|

| Inert (Vacuum/Argon) | Up to ~3,600°C (sublimation) | Atomic bond strength |

| Air (Oxygen Present) | ~450°C - 500°C | Oxidation (material burns away) |

Need a high-temperature solution for your lab? Graphite's performance depends heavily on the application environment. The experts at KINTEK specialize in lab equipment and consumables, including high-purity graphite crucibles, heating elements, and furnace fixtures designed for vacuum or inert-gas use. We can help you select the right grade of graphite or an alternative material to ensure safety, efficiency, and longevity for your specific high-temperature process.

Contact our technical team today for a personalized consultation and unlock the full potential of high-temperature materials in your laboratory.

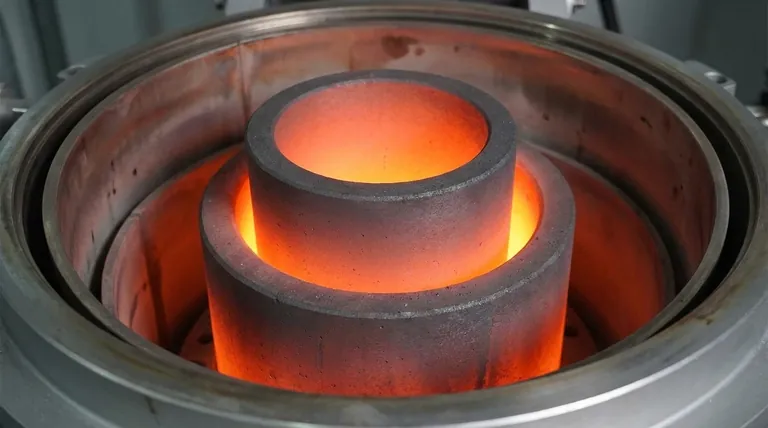

Visual Guide

Related Products

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- What is liquid phase sintering and how is it different from solid state sintering? A Guide to Faster, Denser Materials

- What are the advantages and disadvantages of heat treatment? Master Material Properties for Your Application

- How does a pyrolysis system work? Transforming Waste into Fuel and Chemicals

- What are zeolites advantages and disadvantages? Maximize Molecular Selectivity and Efficiency

- How does a laboratory constant temperature drying oven ensure repeatability? Standardize Your Catalyst Cycling Results

- What is the mechanism of RF reactive sputtering? Create High-Quality Insulating and Compound Films

- How do you clean a sputtering target? Achieve Stable, High-Quality Thin-Film Deposition

- How does microwave sintering work? Achieve Faster, More Uniform Heating for Your Materials