Yes, you can and should vacuum certain parts of your home furnace. This is a fundamental step in routine HVAC maintenance that can improve your system's efficiency and lifespan. However, it's crucial to understand which components are safe to clean and to follow a strict safety-first procedure before you begin.

The core principle is simple: vacuuming removes dust and debris that hinder airflow and combustion. But your absolute first priority must be to completely shut off all electrical power and fuel supply to the unit to prevent serious injury and damage.

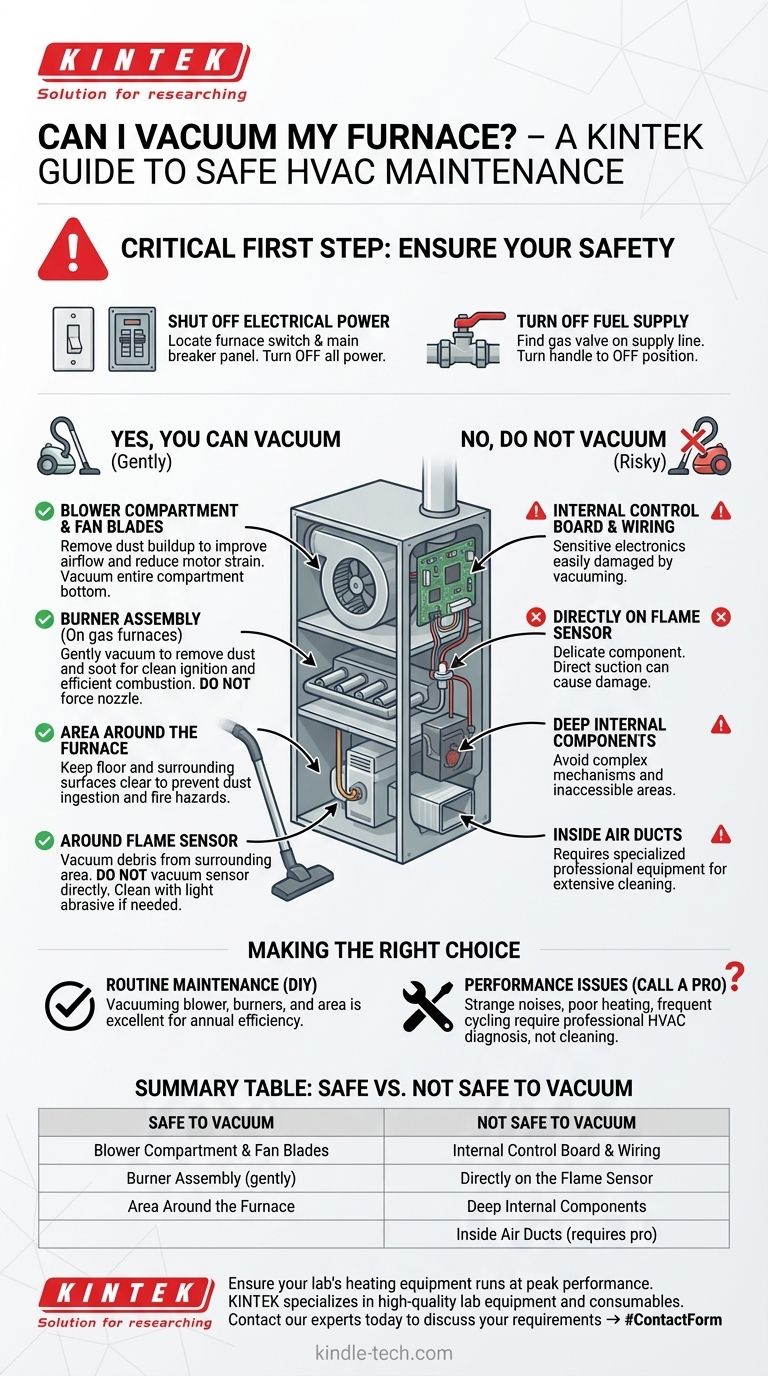

The Critical First Step: Ensuring Your Safety

Before you even think about opening an access panel, you must neutralize any risk of electrical shock or gas leaks. This is not optional.

Shutting Off Electrical Power

Locate the light switch-style power cutoff often mounted on or near the furnace and turn it off. For absolute certainty, go to your home's main electrical panel and turn off the breaker dedicated to the furnace.

Turning Off the Fuel Supply

For a gas furnace, find the gas valve on the supply line leading to the unit. Turn the handle so it is perpendicular to the pipe, which shuts off the flow of fuel.

What You Can (and Should) Vacuum

With the power and fuel safely off, you can proceed with cleaning key areas. A standard vacuum with a hose and attachments, particularly a soft brush and a narrow crevice tool, is all you need.

The Blower Compartment

The blower is the fan that pushes conditioned air through your ductwork. Dust buildup on the fan blades can reduce airflow and strain the motor. Carefully vacuum the fan blades and the entire bottom of the compartment to remove accumulated dust and debris.

The Burner Assembly

On a gas furnace, the burners can accumulate dust and minor soot over time. Gently vacuum the burners and the surrounding area. This helps ensure a clean ignition and efficient fuel combustion. Do not force the vacuum nozzle into any small orifices.

The Flame Sensor and Ignitor

These components are critical for safe operation but are also very delicate. You can gently clean a flame sensor with a very light abrasive, like a dollar bill, but do not vacuum it directly. Instead, vacuum up any debris you've cleared from the area around it.

The Area Around the Furnace

Finally, thoroughly vacuum the floor and all surfaces around the furnace. Keeping this area clear prevents dust from being pulled into the system and eliminates potential fire hazards from nearby stored items.

Common Pitfalls and Limitations

Understanding what not to do is just as important as knowing what to do. Attempting to service components beyond your expertise can be ineffective and dangerous.

Avoid Deep Internal Components

Do not attempt to vacuum deep within the furnace's internal workings, especially near the control board or complex wiring. These components are sensitive and can be easily damaged.

Professional Duct Cleaning is Different

Vacuuming the furnace itself is not a substitute for professional duct cleaning. Technicians use powerful, specialized vacuums and tools to clear debris from your entire home's ductwork, which is a far more extensive job.

Knowing When to Call a Technician

If your furnace is making strange noises, failing to heat properly, or cycling on and off frequently, cleaning is not the solution. These are signs of a mechanical or electrical problem that requires a professional diagnosis from a qualified HVAC technician.

Making the Right Choice for Your Goal

Use this guidance to decide on the appropriate course of action for your system.

- If your primary focus is routine annual maintenance: Carefully vacuuming the blower, burners, and surrounding area is an excellent and highly recommended DIY task.

- If your primary focus is solving a performance issue: While cleaning is a good first step, problems like inadequate heating or system malfunctions require a professional service call.

Taking the time to properly clean your furnace is a direct investment in the comfort and safety of your home.

Summary Table:

| Safe to Vacuum | Not Safe to Vacuum |

|---|---|

| Blower Compartment & Fan Blades | Internal Control Board & Wiring |

| Burner Assembly (gently) | Directly on the Flame Sensor |

| Area Around the Furnace | Deep Internal Components |

| Inside Air Ducts (requires pro equipment) |

Ensure your lab's heating equipment runs at peak performance. Just like regular home furnace maintenance is key to efficiency, proper care of your lab furnaces, ovens, and related equipment is critical for accurate results and long service life. KINTEK specializes in high-quality lab equipment and consumables, serving all your laboratory needs. From replacement parts to expert advice on maintenance protocols, we help you maintain a safe and productive lab environment.

Contact our experts today to discuss your specific equipment and consumable requirements → #ContactForm

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- How do electronic flowmeters contribute to the quality control of the nitriding atmosphere? Precision Process Mastery

- How is CBD oil distilled? A Step-by-Step Guide to Purity and Potency

- What is the process of soaking during heat treatment? Achieve Uniform Microstructure for Superior Metal Properties

- What is the history of spark plasma sintering? From 1930s Origins to Modern FAST Technology

- What is the role of the high-power probe-type ultrasonic homogenizer? Achieve Uniform MWCNT/PPy Dispersion

- What is sintering in electronics? A Key Process for High-Performance Components

- What are the tolerances for laser sintering? A Guide to Achieving Accurate SLS Parts

- What are the advantages and disadvantages in metal fabrication? Unlock Unmatched Strength & Design Flexibility