Yes, absolutely. Induction is not only capable of melting metal, it is a primary technology used in modern metallurgy and foundries for this exact purpose. It is a highly efficient and controlled process for melting a vast range of metals, from industrial steel and aluminum to precious metals like gold and silver.

The core principle is not about applying external flame, but about generating heat directly inside the metal itself. By using a powerful, alternating magnetic field, induction induces strong electrical currents within the conductive metal, and the material's own resistance to these currents creates rapid, intense heat that leads to melting.

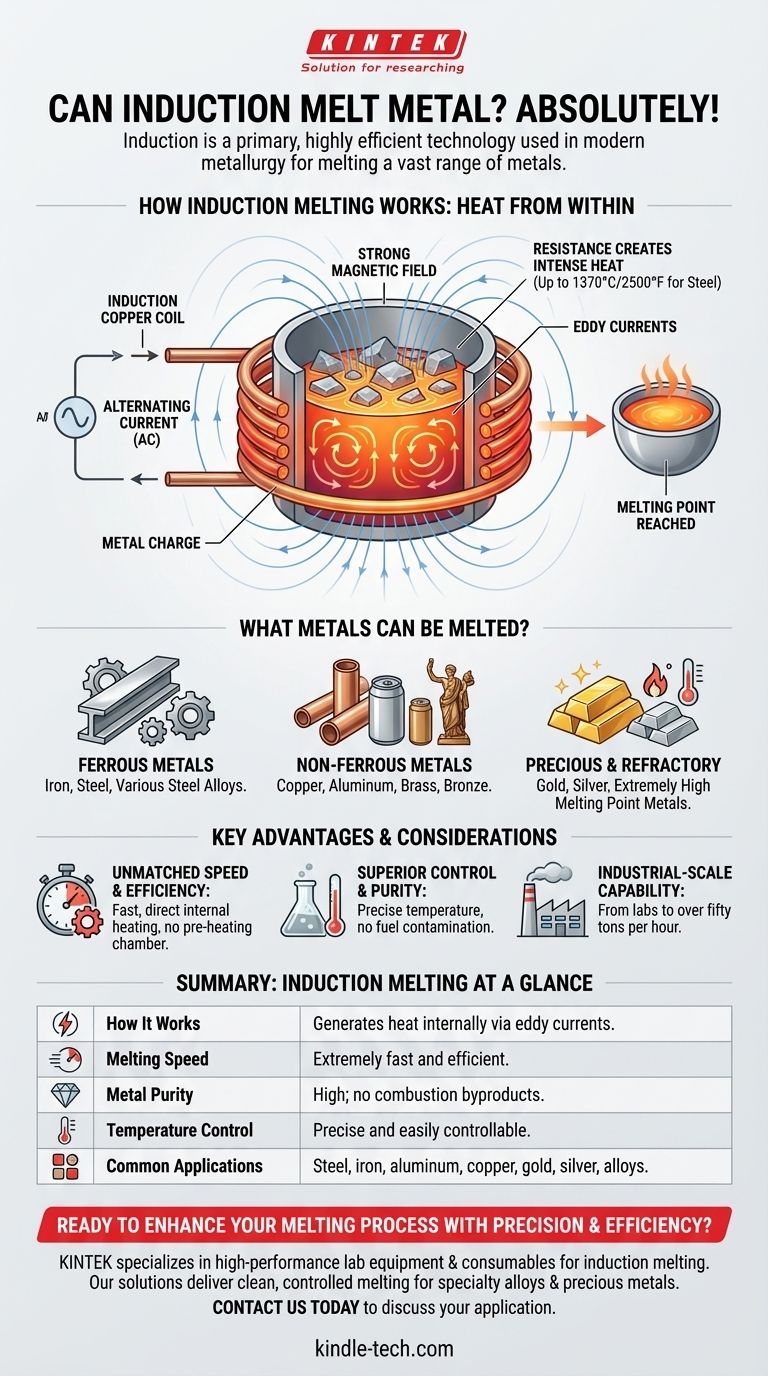

How Induction Melting Works: Heat from Within

Induction melting is a non-contact process that relies on the principles of electromagnetism. The system, known as an induction furnace, uses a few key components to achieve extremely high temperatures.

The Power of the Coil

The process starts with a coil, typically made of highly conductive copper tubing. A powerful alternating electrical current (AC) is passed through this coil.

Generating a Magnetic Field

This alternating current flowing through the coil generates a strong and rapidly changing magnetic field in the space within and around the coil.

Inducing "Eddy" Currents

When a conductive material, such as a piece of steel or aluminum, is placed inside this magnetic field, the field induces electrical currents within the metal. These are known as eddy currents.

Resistance Creates Intense Heat

The metal has a natural resistance to the flow of these eddy currents. This resistance converts the electrical energy into immense heat, causing the metal's temperature to rise rapidly. This internal heating continues until the metal reaches and surpasses its melting point, such as 1370°C (2500°F) for steel.

What Metals Can Be Melted?

The versatility of induction furnaces is one of their greatest strengths. The process works on a wide array of electrically conductive metals.

Ferrous Metals

This is a primary application for induction furnaces. They are commonly used to melt all grades of iron, steel, and various steel alloys from raw materials or scrap.

Non-Ferrous Metals

Induction is highly effective for melting non-ferrous metals. This includes common industrial materials like copper, aluminum, brass, and bronze.

Precious and Refractory Metals

The high temperatures and clean melting environment make induction ideal for high-value materials. This includes precious metals like gold and silver, as well as refractory metals that have extremely high melting points.

Key Advantages and Considerations

Induction melting is not just one option among many; it is often the preferred method due to several distinct advantages over traditional fuel-fired furnaces.

Unmatched Speed and Efficiency

Because heat is generated directly within the material, the melting process is incredibly fast and efficient. There is no need to first heat a chamber and then transfer that heat to the metal.

Superior Control and Purity

The process allows for precise temperature control, which is critical when working with specific alloys. Furthermore, because there is no combustion of fuel, there are no byproducts to contaminate the metal, resulting in a cleaner and higher-quality melt.

Industrial-Scale Capability

While used in labs and small foundries, induction melting is a true industrial powerhouse. Modern induction melters have capacities that can range from one to over fifty tons per hour.

Making the Right Choice for the Application

Understanding the strengths of induction melting helps clarify its role in modern industry.

- If your primary focus is large-scale steel and iron production: Induction is a leading choice for its speed, cleanliness, and efficiency in handling everything from pure iron to alloyed waste.

- If your primary focus is high-purity specialty alloys: The controlled, non-contact heating of an induction furnace is ideal, as it prevents contamination from fuel or electrodes.

- If your primary focus is precious metals or high-value materials: Induction offers the precise temperature control needed to minimize material loss and ensure the highest quality melt.

Ultimately, induction melting is a cornerstone of modern metallurgy, offering an unparalleled combination of speed, precision, and cleanliness.

Summary Table:

| Key Aspect | Details |

|---|---|

| How It Works | Generates heat internally via induced electrical currents (eddy currents). |

| Melting Speed | Extremely fast and efficient due to direct internal heating. |

| Metal Purity | High; no combustion byproducts to contaminate the melt. |

| Temperature Control | Precise and easily controllable. |

| Common Applications | Melting steel, iron, aluminum, copper, gold, silver, and alloys. |

Ready to enhance your melting process with precision and efficiency? KINTEK specializes in high-performance lab equipment and consumables, including induction melting systems tailored for laboratory and small-scale foundry needs. Whether you're working with specialty alloys or precious metals, our solutions deliver the clean, controlled melting you require. Contact us today to discuss how we can support your specific application!

Visual Guide

Related Products

- Non Consumable Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Multi-zone Laboratory Tube Furnace

People Also Ask

- What is the primary function of a vacuum arc melting furnace in RHEA preparation? Achieving Extreme Thermal Fusion

- What are the advantages and disadvantages of brazing? A Guide to Strong, Clean Metal Joining

- What is the primary function of vacuum melting equipment in Ti-Zr-Ni alloy preparation? Ensure Purity and Phase Stability

- What is the role of a laboratory vacuum arc remelting furnace? Mastering High-Entropy Alloy Synthesis

- Does higher heat capacity mean higher melting point? Unraveling the Critical Difference