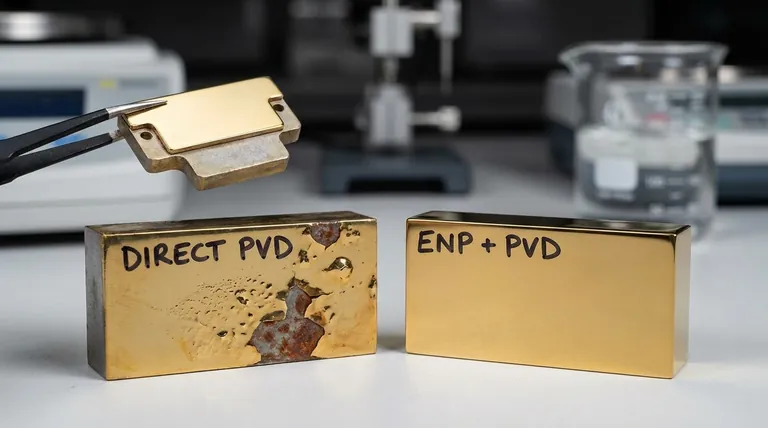

Yes, PVD coating can be applied to mild steel, but it is almost never a successful or durable solution when applied directly. The fundamental properties of mild steel, primarily its extreme susceptibility to corrosion, create a critical incompatibility with the nature of thin-film PVD coatings. A direct application will inevitably lead to rapid failure as rust forms beneath the PVD layer, causing it to delaminate and flake off.

The core problem is not one of adhesion but of corrosion. To successfully apply a PVD coating to mild steel, you must first seal the steel with a dense, corrosion-resistant underlayer—typically electroless nickel or chrome plating—which serves as a stable foundation for the final PVD finish.

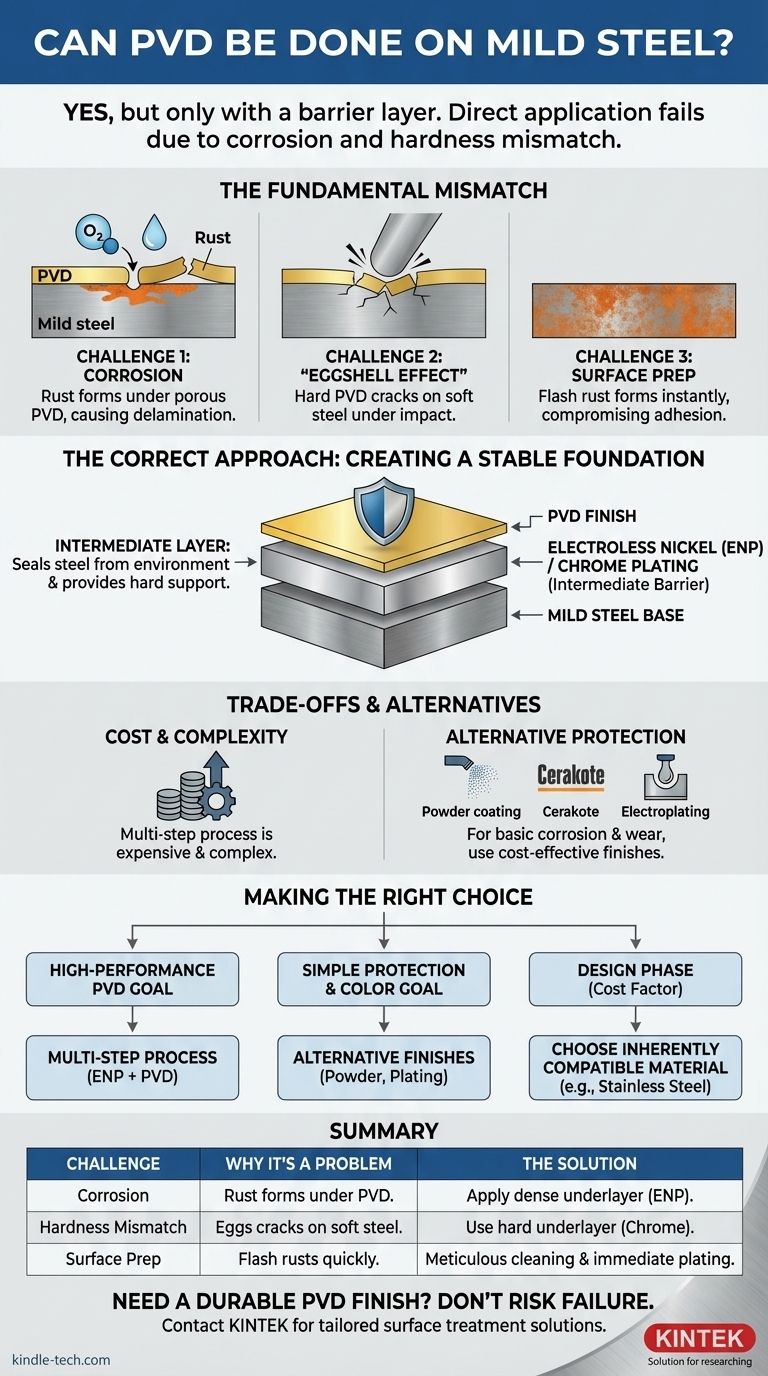

The Fundamental Mismatch: PVD and Mild Steel

Applying a high-performance, precision coating like PVD onto a low-cost, reactive material like mild steel presents several technical challenges. Understanding these issues is key to avoiding costly and predictable failures.

The Primary Challenge: Inevitable Corrosion

PVD coatings are microscopically thin, often measuring only a few microns. Despite their density, they can contain microscopic pores, pinholes, or defects.

On a non-reactive substrate like stainless steel or titanium, these tiny imperfections are insignificant. On mild steel, however, each pinhole becomes a gateway for moisture and oxygen to reach the steel and initiate rust.

This corrosion begins underneath the PVD coating. As the rust expands, it lifts the coating from the surface, leading to blistering, flaking, and complete failure of the finish.

The "Eggshell Effect": Hardness Incompatibility

PVD coatings like Titanium Nitride (TiN) are extremely hard, often exceeding 70 HRC. Mild steel, by contrast, is very soft and ductile.

Placing an ultra-hard, thin layer on a soft base creates what is known as the "eggshell effect." Any impact that deforms the soft steel underneath will cause the brittle PVD coating to crack and fracture, as it has no structural support.

The Issue of Surface Preparation

PVD requires an immaculately clean, pristine surface to achieve proper adhesion. Mild steel is often supplied with mill scale, rust, or oils that must be completely removed.

Even after meticulous cleaning, the surface of mild steel begins to flash rust almost immediately upon exposure to air, compromising the ideal conditions required for the PVD process.

The Correct Approach: Creating a Stable Foundation

The only reliable method for applying PVD to mild steel involves a multi-step process where intermediate layers solve the steel's inherent weaknesses.

The Role of an Intermediate Layer

The solution is to first apply a barrier coating that completely seals the mild steel from the environment. This layer must be dense, non-porous, and provide excellent corrosion resistance.

This intermediate layer serves two purposes: it protects the steel from rusting, and it provides a hard, stable surface that is perfectly suited for PVD application.

Recommended Underlayer: Electroless Nickel (ENP)

Electroless nickel plating is the industry-standard solution. It provides a uniform, non-porous coating that offers exceptional corrosion resistance.

A layer of medium- or high-phosphorous ENP creates an ideal, hard foundation that eliminates the risk of underlying rust and provides better support for the final PVD film.

Alternative Underlayer: Chrome Plating

Hard chrome plating can also serve as an effective underlayer for PVD. It provides both the necessary corrosion barrier and a very hard surface that supports the PVD coating well.

Understanding the Trade-offs and Alternatives

While technically possible with the right preparation, this multi-step process introduces significant considerations that you must weigh against your project goals.

The Factor of Cost

The primary reason for using mild steel is its low cost. However, the process of properly preparing and plating it before PVD adds significant expense and complexity.

This multi-step process (degreasing, sandblasting, nickel plating, PVD coating) can often be more expensive than simply manufacturing the part from a more suitable material, like 300-series stainless steel, in the first place.

When to Consider Other Finishes

If your goal is simply to protect mild steel and provide a durable, decorative finish, PVD is often overkill.

More cost-effective and direct solutions like powder coating, Cerakote, or traditional zinc and chrome electroplating are often better suited for protecting mild steel parts from corrosion and wear.

Making the Right Choice for Your Goal

To determine the best path forward, evaluate the true objective of your project.

- If your primary focus is achieving a specific high-performance PVD finish (like TiN or DLC) on a mild steel part: You must budget for a multi-step process that includes a high-quality electroless nickel or chrome plating underlayer.

- If your primary focus is simply corrosion resistance and a durable color: PVD is not the right tool. Investigate more direct and economical finishes like powder coating, electroplating, or industrial painting.

- If you are in the design phase and cost is a factor: It is almost always more efficient and cost-effective to choose a substrate material that is inherently compatible with PVD, such as stainless steel.

Understanding the limitations of your base material is the key to selecting a surface treatment that provides lasting performance rather than a costly failure.

Summary Table:

| Challenge | Why It's a Problem | The Solution |

|---|---|---|

| Corrosion | Rust forms under the thin PVD layer, causing delamination. | Apply a dense underlayer like electroless nickel to seal the steel. |

| Hardness Mismatch | Hard PVD coating cracks on soft mild steel (eggshell effect). | Use a hard underlayer (e.g., chrome plating) for support. |

| Surface Prep | Mild steel rusts quickly, compromising PVD adhesion. | Meticulous cleaning and immediate plating are required. |

Need a durable PVD finish on steel? Don't risk failure.

At KINTEK, we specialize in precision lab equipment and consumables, including surface treatment solutions. Our experts can help you select the right substrate and coating process to ensure lasting performance—whether you're working with mild steel, stainless steel, or specialized alloys.

Contact us today to discuss your project and get a tailored solution that avoids costly mistakes. Reach out via our contact form for a consultation!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Electrolytic Electrochemical Cell for Coating Evaluation

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Lab-Scale Vacuum Induction Melting Furnace

People Also Ask

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- Is diamond coating worth it? Maximize Component Life and Performance

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers