Yes, Physical Vapor Deposition (PVD) can be successfully applied to plastic, but it is a common misconception that the process is the same as for metals. Applying PVD to plastic requires a specialized, low-temperature approach and critical surface preparation to overcome the inherent limitations of polymer substrates, such as their low melting point.

The core challenge of applying PVD to plastics is not the deposition itself, but preparing the plastic to survive the vacuum environment and accept the coating. Success almost always depends on using a low-temperature PVD process in combination with a specially formulated base coat.

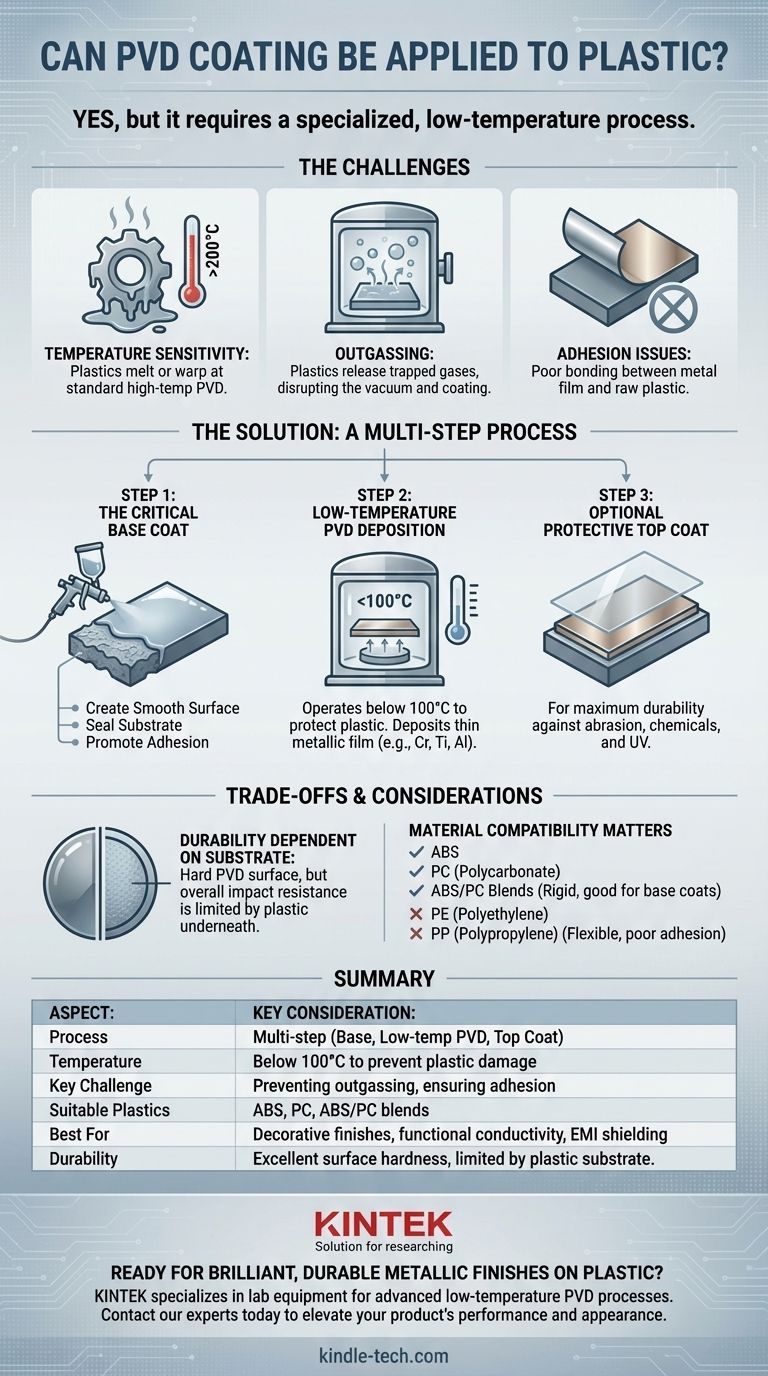

Why Coating Plastic is Fundamentally Different

While PVD is a line-of-sight, vacuum-based process for all materials, plastic substrates introduce unique challenges that are not present with metals or ceramics.

The Challenge of Temperature

Standard PVD processes for tools and metal parts often operate at high temperatures (200-500°C) to ensure strong adhesion and a dense coating structure.

Most common plastics, like ABS or Polycarbonate, would melt, warp, or degrade at these temperatures, making this traditional method unsuitable.

The Problem of Outgassing

Under the high vacuum required for PVD, plastics have a tendency to outgas. This means they release trapped gases, moisture, and other volatile compounds from within the material.

This outgassing can disrupt the vacuum, contaminate the chamber, and prevent the coating from forming a clean, uniform, and well-adhered layer.

The Issue of Adhesion

A metallic PVD film does not naturally form a strong chemical or mechanical bond with a raw plastic surface. Without proper preparation, the coating is likely to delaminate, flake, or fail basic adhesion tests.

The Solution: A Multi-Step Process

To overcome these challenges, applying PVD to plastics is typically not a single step but a carefully controlled sequence.

Step 1: The Critical Base Coat

Before entering the PVD chamber, the plastic part is almost always coated with a UV-cured lacquer or primer. This base coat is the key to success.

This layer serves three critical functions:

- Creates a Smooth Surface: It fills in microscopic pores and imperfections in the plastic, providing a glass-like finish for the PVD layer.

- Seals the Substrate: It acts as a barrier, preventing the plastic from outgassing under vacuum.

- Promotes Adhesion: It is specifically formulated to bond strongly to both the plastic substrate below and the metallic PVD film above.

Step 2: Low-Temperature PVD Deposition

Once the base coat is applied and cured, the part is placed in the PVD chamber. A low-temperature PVD process, such as sputtering, is used.

These processes operate at temperatures well below 100°C, ensuring that neither the plastic substrate nor the base coat is damaged during deposition. This deposits the thin metallic film (like chromium, titanium, or aluminum) onto the prepared surface.

Step 3 (Optional): The Protective Top Coat

For applications requiring maximum durability against abrasion, chemicals, or UV exposure, a final transparent top coat (often another UV-cured acrylic or lacquer) can be applied over the PVD layer.

Understanding the Trade-offs and Limitations

While effective, this process has considerations that differ from coating directly onto metal.

Durability is Substrate-Dependent

A PVD coating is exceptionally hard, but it is also exceptionally thin (a few microns). Its overall durability and impact resistance are ultimately limited by the hardness of the material underneath it.

A PVD-coated plastic part will have excellent surface hardness for abrasion resistance but will still dent or deform like plastic upon heavy impact.

Material Compatibility Matters

Certain plastics are better suited for this process. Materials like ABS, PC (Polycarbonate), and ABS/PC blends are commonly used because they are rigid and accept base coats well.

Softer or more flexible plastics like Polyethylene (PE) or Polypropylene (PP) are much more difficult to coat due to poor adhesion and are generally not suitable candidates.

Process Complexity and Cost

The multi-step nature—requiring a base coat, specialized low-temperature PVD, and potentially a top coat—makes the process more complex and often more costly than applying PVD directly to a metal component.

Making the Right Choice for Your Project

Use this guidance to determine if PVD is the right solution for your plastic component.

- If your primary focus is a premium decorative finish: This process is an excellent choice for achieving a brilliant, durable, and uniform metallic look on plastic parts for automotive, cosmetic, or consumer electronics applications.

- If your primary focus is extreme wear resistance: Acknowledge that while the surface will be highly scratch-resistant, the overall part's durability is limited by the underlying plastic. It will not make a plastic part perform like a steel one.

- If your primary focus is functional conductivity or EMI shielding: Low-temperature PVD is a highly effective method for applying a thin, uniform conductive layer onto complex plastic geometries.

By understanding this specialized approach, you can successfully leverage PVD to elevate the performance and appearance of plastic components.

Summary Table:

| Aspect | Key Consideration |

|---|---|

| Process | Multi-step: Base coat, low-temp PVD, optional top coat |

| Temperature | Must be below 100°C to prevent plastic damage |

| Key Challenge | Preventing outgassing and ensuring adhesion |

| Suitable Plastics | ABS, Polycarbonate (PC), ABS/PC blends |

| Best For | Decorative finishes, functional conductivity, EMI shielding |

| Durability | Excellent surface hardness, but limited by plastic substrate |

Ready to achieve a brilliant, durable metallic finish on your plastic components?

KINTEK specializes in providing the lab equipment and consumables needed for advanced coating processes like low-temperature PVD. Whether you are developing new products in automotive, consumer electronics, or cosmetics, our solutions can help you ensure precision, quality, and efficiency in your coating applications.

Contact our experts today to discuss how we can support your specific plastic coating challenges and help you elevate your product's performance and appearance.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications