Yes, sintered metal components can absolutely be machined, but doing so requires a specific approach that accounts for their unique internal structure. Unlike solid metals, sintered parts are formed from pressed and heated powder, resulting in inherent porosity that fundamentally changes how they interact with a cutting tool. Understanding this distinction is the key to successfully achieving the desired tolerances and surface finish without damaging the part or prematurely wearing out your tools.

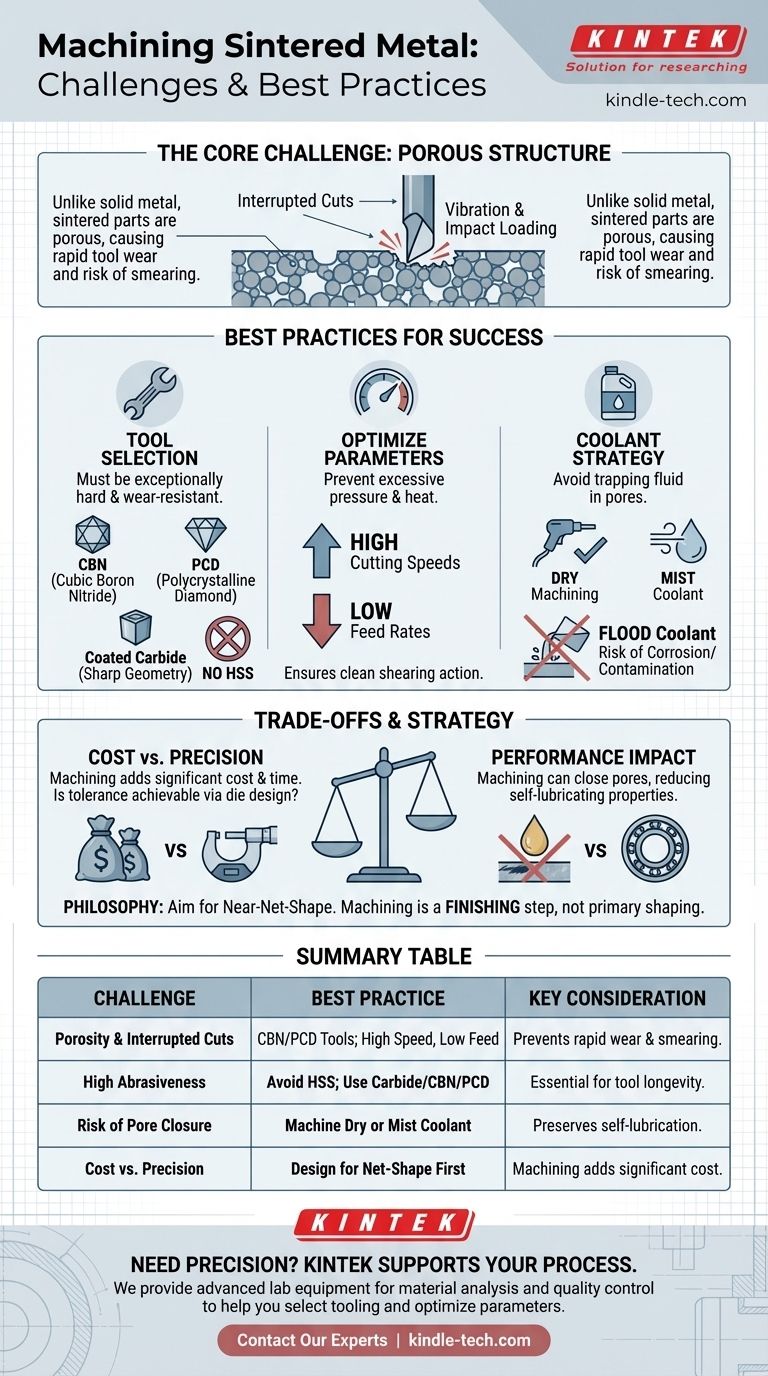

The central challenge in machining sintered metal is its porous structure. This porosity leads to interrupted cuts on a microscopic level, causing rapid tool wear and requiring specialized tools and techniques to prevent smearing the surface and closing the very pores that often give the part its desired properties.

Why Machining Sintered Metal is a Unique Challenge

The powder metallurgy (sintering) process is designed to create parts that are "near-net-shape," minimizing the need for secondary operations. However, when features like threads, sharp corners, or high-precision bores are required, machining becomes necessary.

The Decisive Role of Porosity

A sintered part is not a solid block of metal; it's a rigid sponge of fused metallic particles. When a cutting tool moves across the surface, its edge is constantly moving from metal to void and back again.

These microscopic interrupted cuts create vibration and impact loading that can chip delicate tool edges and accelerate wear far more quickly than when cutting a solid, homogenous material.

High Abrasiveness and Rapid Tool Wear

The individual powder particles in a sintered component are bonded together by heat and pressure, but they are not fully melted and reformed. This granular structure can be highly abrasive.

As a result, standard high-speed steel (HSS) tools will fail almost immediately. Harder, more wear-resistant cutting tool materials are not optional—they are a requirement.

The Risk of Smearing and Closing Pores

Many sintered parts, particularly bronze or iron bearings, are designed to be porous so they can be impregnated with oil for self-lubrication.

Aggressive or improper machining techniques can "smear" the surface metal, plastically deforming it and closing off these essential pores. This can permanently destroy the part's self-lubricating capability.

Best Practices for Machining Sintered Parts

To counter these challenges, you must adapt your tools, parameters, and processes. The goal is to create a clean shearing action rather than pushing or tearing the material.

Tool Selection is Critical

Your first line of defense is the cutting tool itself. The tool must be exceptionally hard and wear-resistant.

Use Cubic Boron Nitride (CBN) or Polycrystalline Diamond (PCD) tools for the best performance and tool life, especially on ferrous sintered materials. At a minimum, use uncoated or, preferably, coated carbide tools with a very sharp, positive rake angle geometry.

Optimize Your Cutting Parameters

The right speeds and feeds are crucial to prevent excessive tool pressure and heat.

Generally, you should use high cutting speeds combined with low feed rates. High speed helps maintain a stable cutting zone, while a low feed rate reduces the pressure on the tool and minimizes the risk of smearing the part's surface.

Use Coolant Cautiously

Flooding a sintered part with liquid coolant can be problematic. The fluid can become trapped in the porous network, leading to later corrosion or contamination.

When possible, machining dry is the preferred method. If cooling is necessary, a mist coolant or a directed jet of compressed air is a much safer alternative to flood cooling.

Understanding the Trade-offs

Machining should be viewed as a finishing operation for sintered parts, not a primary shaping method. Always weigh the benefits against the drawbacks.

Cost vs. Precision

The primary advantage of sintering is its low cost for high-volume production of complex shapes. Adding a machining step introduces significant cost and time, eroding this core benefit.

Always ask if the required tolerance can be achieved through better die design or sintering process control before resorting to machining.

Performance Impact on Self-Lubricating Parts

If you are machining a part specifically designed for its porosity (like an oil-impregnated bearing), you are altering its fundamental properties.

Even with perfect technique, some level of surface pore closure is inevitable. This will reduce the part's ability to store and deliver lubricant, potentially leading to premature failure in the final application.

The Near-Net-Shape Philosophy

The goal of powder metallurgy is to produce a finished part directly from the die. Designing a component that relies heavily on post-sinter machining often indicates a misalignment between the design requirements and the chosen manufacturing process.

Making the Right Choice for Your Project

Evaluate your design goals to determine if and how you should approach machining a sintered component.

- If your primary focus is lowest possible cost: Design the part to be truly net-shape from the sintering process and avoid all secondary machining.

- If your primary focus is high precision on specific features: Plan for machining as a final finishing step, but specify the correct tooling (CBN/PCD) and parameters in your manufacturing plan.

- If your primary focus is self-lubrication: Avoid machining any surface that requires porosity; if a feature must be machined, be aware that its lubricating properties will be compromised.

Ultimately, successful manufacturing comes from designing the part with a deep understanding of the production process from the very beginning.

Summary Table:

| Challenge | Best Practice | Key Consideration |

|---|---|---|

| Porosity & Interrupted Cuts | Use CBN or PCD tools; high speed, low feed | Prevents rapid tool wear and surface smearing |

| High Abrasiveness | Avoid HSS; use carbide, CBN, or PCD tools | Essential for tool longevity and clean cuts |

| Risk of Pore Closure | Machine dry or with mist coolant; avoid flood cooling | Preserves self-lubricating properties in bearings |

| Cost vs. Precision | Design for net-shape first; machine only when necessary | Machining adds significant cost to the sintering process |

Need to machine a complex sintered component with precision?

KINTEK specializes in providing the advanced lab equipment and consumables necessary for developing and testing high-performance sintered metals. Our expertise supports the entire manufacturing process, from material analysis to final quality control.

We help you:

- Select the right tooling for your specific sintered material.

- Optimize machining parameters to achieve perfect tolerances without compromising part integrity.

- Ensure quality with equipment designed for rigorous material testing.

Let's discuss your project requirements. Contact our experts today to find the ideal solution for your laboratory and production needs.

Visual Guide

Related Products

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Laboratory Hybrid Tissue Grinding Mill

People Also Ask

- How does a vacuum affect temperature? Control Heat Transfer for Superior Lab Results

- What are the applications of industrial furnaces? From Metal to Ceramics, Discover High-Temp Solutions

- What is the role of vacuum in deposition methods? Master Purity and Control for Superior Thin Films

- What is the primary role of vacuum heating equipment in halide solid electrolyte synthesis? Achieve High Conductivity

- What is the temperature of a calcination furnace? Unlocking the Key to Your Material's Transformation

- What are the disadvantages of vacuum evaporation? Understanding the Trade-offs in Thin-Film Deposition

- How is vacuum brazing done? Achieve High-Strength, Flux-Free Metal Joining

- How do gas nozzles facilitate energy recycling in activation furnaces? Enhance Efficiency in Activated Carbon Production