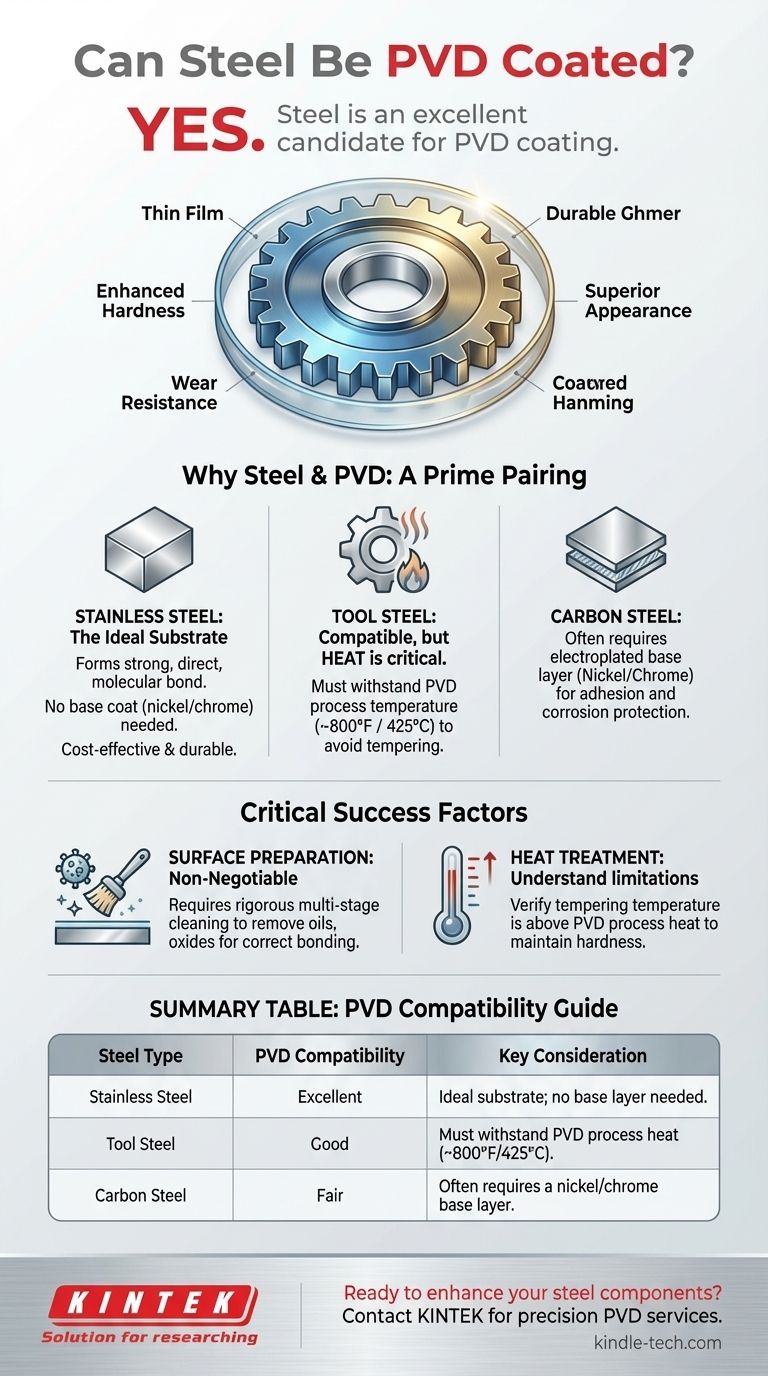

Yes, steel is an excellent and common candidate for PVD coating. Physical Vapor Deposition (PVD) can be applied directly to many types of steel, with stainless steel being a particularly ideal substrate due to its inherent properties. The process creates a thin, durable film that enhances the steel's surface characteristics, such as hardness, wear resistance, and appearance.

While PVD can be applied to various steels, the success of the coating hinges on the specific type of steel and its ability to withstand the process temperature. Stainless steel is a preferred material because it forms a strong, direct bond with the PVD coating without requiring an intermediate layer.

Why Steel is a Prime Substrate for PVD

PVD coatings and steel substrates are a common pairing in many industries, from decorative hardware to high-performance tooling. This is due to a natural compatibility that enhances the final product's performance.

The Advantage of Stainless Steel

Stainless steel is arguably the best steel substrate for PVD. Its surface chemistry and stability allow for a direct and robust bond with the vaporized coating material.

Because of this, stainless steel does not require a preliminary base coat, such as nickel or chrome. This simplifies the coating process, making it more cost-effective.

Direct and Strong Adhesion

PVD coatings exhibit excellent adherence when applied directly to a clean stainless steel surface. The resulting bond is molecular, creating a finish that is highly resistant to chipping, flaking, or peeling.

This strong adhesion ensures the functional benefits of the PVD coating—like increased hardness and lubricity—are effectively transferred to the steel component.

Compatibility with Other Steel Types

While stainless steel is ideal, it is not the only option. Other types, such as tool steels, are also frequently coated with PVD.

The key requirement for any metal is its ability to withstand the heat of the PVD chamber, which can reach up to 800°F (approximately 425°C).

Understanding the Trade-offs and Limitations

Applying a PVD coating to steel is a highly effective surface treatment, but success depends on understanding its limitations. Ignoring these factors can lead to poor adhesion, component failure, or unexpected changes in material properties.

Heat Treatment is a Critical Factor

The temperature of the PVD process is a crucial constraint. This heat can affect the temper and hardness of certain heat-treated steels.

If a tool steel has been tempered at a temperature lower than the PVD process temperature, the coating process will soften it, compromising its mechanical properties. You must verify that the steel's tempering temperature is safely above that of the PVD process.

Not All Steels Are Created Equal

While PVD can be applied to "various types of steel," the quality of the substrate is paramount. Low-grade steels or those with surface impurities will result in a poor-quality finish.

For standard carbon steels, a base layer of nickel or chrome plating is often recommended before applying the PVD topcoat to ensure maximum adhesion and corrosion resistance.

Surface Preparation is Non-Negotiable

Even though stainless steel doesn't require a base layer, it absolutely requires a perfectly clean surface. Any oils, oxides, or microscopic debris will prevent the coating from bonding correctly.

All steel parts must undergo a rigorous, multi-stage cleaning and inspection process immediately before entering the PVD chamber.

Making the Right Choice for Your Steel Project

Your choice of steel and preparation method directly impacts the quality and performance of the final PVD-coated component. Use your primary goal to guide your approach.

- If your primary focus is maximum durability and cost-efficiency: Use a high-quality stainless steel (like 303, 304, or 440C) as your substrate to achieve excellent adhesion without needing an intermediate plating layer.

- If your primary focus is coating a hardened tool steel: Verify that the steel's tempering temperature is significantly higher than the PVD process temperature (typically 800°F / 425°C) to prevent altering its hardness.

- If your primary focus is applying a decorative finish to standard carbon steel: Plan for an electroplated base layer of nickel and/or chromium to ensure a flawless surface for PVD adhesion and long-term corrosion protection.

By matching your steel substrate to the requirements of the PVD process, you can confidently create components with superior surface performance and aesthetics.

Summary Table:

| Steel Type | PVD Compatibility | Key Consideration |

|---|---|---|

| Stainless Steel | Excellent | Ideal substrate; no base layer needed. |

| Tool Steel | Good | Must withstand PVD process heat (~800°F/425°C). |

| Carbon Steel | Fair | Often requires a nickel/chrome base layer for adhesion. |

Ready to enhance your steel components with a durable, high-performance PVD coating?

KINTEK specializes in precision PVD coating services for laboratory equipment and industrial components. We help you select the right steel and coating combination to achieve superior hardness, wear resistance, and a flawless aesthetic finish.

Contact our experts today to discuss your project and receive a tailored solution that meets your exact specifications.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition