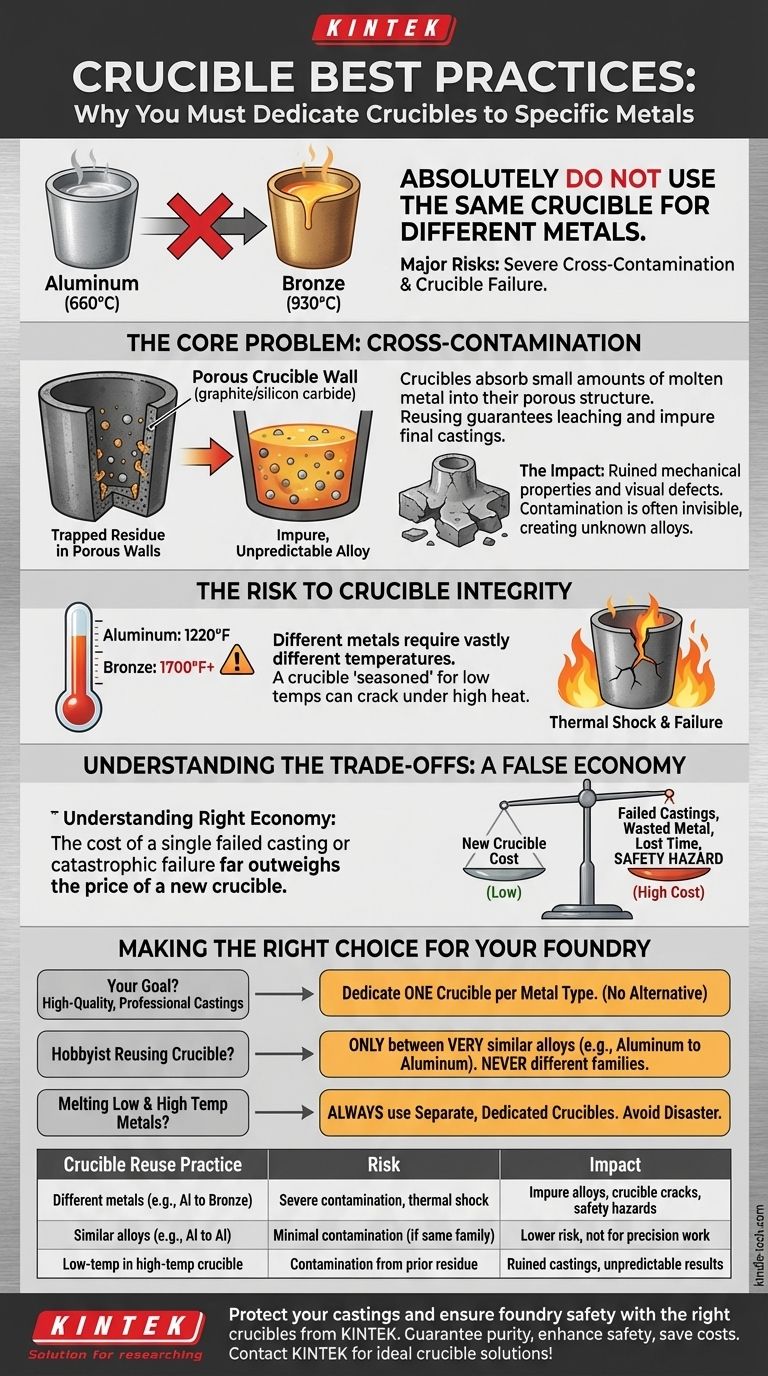

While you technically can, you absolutely should not use the same crucible for different metals. This practice is strongly discouraged in any serious foundry work because it introduces two major problems: severe cross-contamination of your alloys and a significant risk of crucible failure.

The core principle is that a crucible absorbs small amounts of whatever metal is melted within it. Reusing it for a different metal guarantees that this trapped residue will leach out, creating an impure, unpredictable alloy and compromising the quality of your final casting.

The Core Problem: Cross-Contamination

The primary reason to dedicate crucibles to specific metals is to maintain the purity and integrity of your alloys. Even minuscule amounts of a foreign metal can have drastic effects.

How Contamination Occurs

Crucibles, especially those made of clay-graphite or silicon carbide, have a porous structure. When metal is in its molten state, it penetrates these microscopic pores.

After the crucible cools, this metal becomes trapped within the crucible walls. No amount of scraping or cleaning can completely remove this embedded residue.

The Impact on Your Alloys

When you introduce a new, different metal and bring it to melting temperature, the old, trapped metal will melt as well and mix into your new batch.

For example, a small amount of aluminum residue contaminating a bronze melt can ruin its mechanical properties and finish. Likewise, zinc from a previous brass melt can cause brittleness and casting defects in an aluminum pour.

The "Invisible" Damage

This contamination isn't always obvious. The contaminated casting might look visually acceptable but will fail to meet the expected standards for strength, ductility, or corrosion resistance. You've created an unknown, uncontrolled alloy.

The Risk to Your Crucible's Integrity

Beyond contamination, using the same crucible for different metals can physically damage the crucible itself, creating a significant safety hazard.

Different Metals, Different Temperatures

Metals have vastly different melting points. Aluminum melts around 1220°F (660°C), while bronze and brass require temperatures over 1700°F (930°C).

A crucible that has been repeatedly used for a low-temperature metal like aluminum becomes "seasoned" to that temperature range.

Thermal Shock and Chemical Attack

Subjecting a crucible seasoned for aluminum to the much higher temperatures required for bronze can cause severe thermal shock, leading to cracks or outright failure.

Furthermore, the fluxes used for different metals can have different chemical effects. An aggressive flux used for one alloy might prematurely erode a crucible that was stable with a different alloy and flux combination.

Understanding the Trade-offs

The motivation for reusing a crucible is almost always to save money. However, this is a classic example of a false economy.

The Perceived Benefit: Cost Savings

On the surface, purchasing fewer crucibles seems like an obvious way to reduce operational costs. A new crucible can feel like an unnecessary expense when you have one that appears perfectly usable.

The Hidden Costs: Failed Castings

The cost of a single failed casting almost always outweighs the cost of a new crucible. This includes the wasted metal, the fuel or electricity used for the melt, and, most importantly, your time and labor.

The Critical Safety Factor

The most significant hidden cost is the risk of catastrophic crucible failure. A crucible that breaks apart while full of molten metal is one of the most dangerous events that can occur in a foundry, potentially causing severe burns and fires.

Making the Right Choice for Your Foundry

Your crucible strategy should directly align with your goals for quality, safety, and efficiency.

- If your primary focus is high-quality, professional castings: You must dedicate one crucible for each specific type of metal or alloy. There is no alternative for achieving predictable results.

- If you are a hobbyist who absolutely must reuse a crucible: Only consider it between very similar alloys within the same metal family (e.g., from one aluminum alloy to another). Never switch between different metal families like aluminum and copper.

- If you need to melt both low- and high-temperature metals: Always use separate, dedicated crucibles. Subjecting a low-temp crucible to high temperatures is courting disaster.

- If you are considering melting a low-temp metal in a high-temp crucible: The risk is not crucible failure, but severe contamination from the higher-temperature metal that has saturated the crucible walls.

Investing in dedicated crucibles is the single best practice for guaranteeing the integrity of your work and the safety of your operation.

Summary Table:

| Crucible Reuse Practice | Risk | Impact |

|---|---|---|

| Different metals (e.g., aluminum to bronze) | Severe cross-contamination, thermal shock | Impure alloys, crucible cracks, safety hazards |

| Similar alloys (e.g., aluminum to aluminum) | Minimal contamination if same family | Lower risk, but not recommended for precision work |

| Low-temp metal in high-temp crucible | Contamination from prior high-temp residue | Ruined castings, unpredictable results |

Protect your castings and ensure foundry safety with the right crucibles from KINTEK.

As a specialist in lab equipment and consumables, KINTEK provides durable, high-purity crucibles designed for specific metals and alloys. Whether you're melting aluminum, bronze, or specialized alloys, using the correct crucible is essential for achieving consistent results and preventing dangerous failures.

- Guarantee alloy purity with crucibles dedicated to each metal type.

- Enhance operational safety by avoiding thermal shock and contamination risks.

- Save time and costs by reducing failed casts and equipment damage.

Don’t compromise on quality or safety—contact KINTEK today to find the ideal crucible solution for your laboratory or foundry needs!

Visual Guide

Related Products

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

People Also Ask

- Why are high-alumina crucibles selected for Cs-zeolite heat treatment? Ensure Sample Purity at 1100 °C

- Why is an alumina crucible selected for the CaCl2-NaCl molten salt system? Ensure High Purity and Thermal Stability

- Why are high-purity Nickel Crucibles selected for molten salt metal stability testing? Ensure Pure & Reliable Data

- What role does an Alumina Crucible play in the high-temperature solid-state synthesis of Na3OBr? Ensure Sample Purity

- Why are zirconia crucibles utilized for LSTH solid electrolytes? Ensure Pure-Phase Synthesis at 1450°C

- Can you clean a crucible? The Definitive Guide to Safe, Effective Crucible Cleaning

- Can you use stainless steel as a crucible? A Guide to Safe & Effective Material Choices

- What is an example of crucible in chemistry? Essential Tools for High-Temperature Reactions