Yes, tungsten is an exceptional heating element, but its use is reserved for very specific, high-temperature applications. Its effectiveness is entirely dependent on the operating environment due to its reaction with oxygen at high temperatures.

Tungsten's primary advantage is its incredibly high melting point, making it one of the few materials capable of generating heat up to 2500°C. However, this benefit comes with a critical requirement: it must be operated in a high-vacuum or protective atmosphere to prevent rapid failure from oxidation.

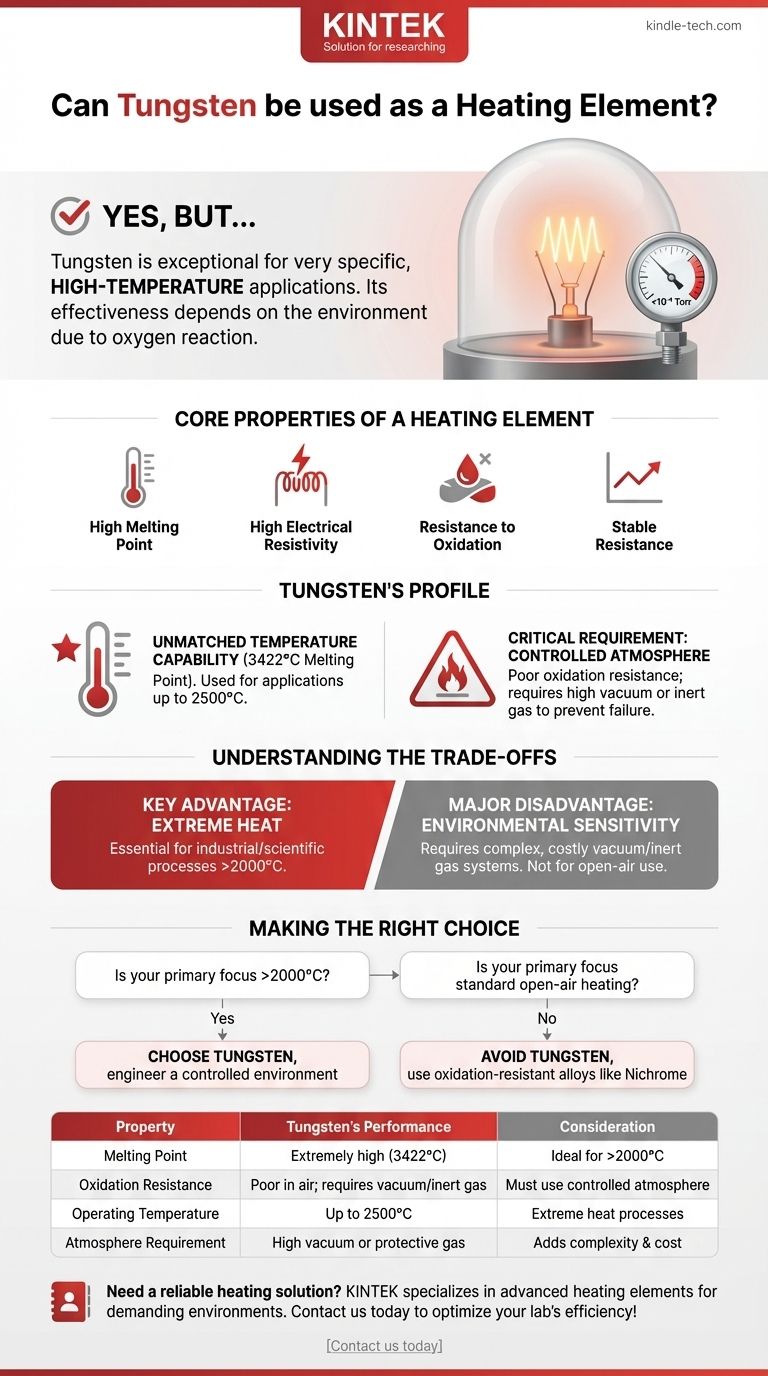

The Core Properties of a Heating Element

To understand where tungsten fits, we must first define what makes any material suitable for generating heat. The choice of material directly impacts the longevity, reliability, and efficiency of the entire heating process.

High Melting Point

A heating element works by getting extremely hot. The material's melting point must be significantly higher than its operating temperature to ensure it remains structurally sound.

High Electrical Resistivity

Heat is generated when electrical current encounters resistance (Joule heating). A material with high resistivity can generate substantial heat efficiently without requiring excessive current.

Resistance to Oxidation

High temperatures dramatically accelerate chemical reactions, especially with oxygen in the air. A good heating element must resist this degradation to have a reasonable service life.

Stable Resistance

As a material heats up, its electrical resistance can change. A low temperature coefficient of resistance ensures that the heat output remains stable and predictable as the element reaches its target temperature.

Tungsten's Profile as a Heating Element

Tungsten excels in one of these categories more than almost any other metal, but it has a significant weakness in another.

Unmatched Temperature Capability

Tungsten has the highest melting point of all metals (3422°C). This unique property allows it to be used in applications requiring extreme heat, such as those reaching 2500°C.

The Critical Requirement: A Controlled Atmosphere

Tungsten's primary drawback is its poor resistance to oxidation at high temperatures. When heated in the presence of air, it burns up and fails very quickly.

To prevent this, it must be shielded. This is why tungsten filaments are used inside vacuum-sealed incandescent bulbs or in specialized high-temperature vacuum furnaces.

Understanding the Trade-offs

Choosing tungsten is a decision based on balancing its unique strength against its demanding operational needs.

Key Advantage: Extreme Heat

For industrial or scientific processes that demand temperatures above what common alloys like nichrome or kanthal can handle, tungsten is often the only viable choice.

Major Disadvantage: Environmental Sensitivity

The need for a high vacuum (less than 10⁻⁴ Torr) or an inert gas atmosphere adds significant complexity and cost to the equipment design. It is not a material you can use for simple, open-air heating coils.

Making the Right Choice for Your Goal

Your application's requirements will determine if tungsten is the correct material.

- If your primary focus is reaching the highest possible temperatures (above 2000°C): Tungsten is an ideal choice, but you must engineer a system that provides a vacuum or protective atmosphere.

- If your primary focus is a standard heating application in open air: Tungsten is entirely unsuitable, and you should use a material designed for oxidation resistance, such as a nickel-chromium or iron-chromium-aluminum alloy.

Ultimately, selecting tungsten is a decision driven by the absolute need for extreme heat, which justifies the cost and complexity of a controlled environment.

Summary Table:

| Property | Tungsten's Performance | Consideration |

|---|---|---|

| Melting Point | Extremely high (3422°C) | Ideal for applications above 2000°C |

| Oxidation Resistance | Poor in air; requires vacuum/inert gas | Must be used in a controlled atmosphere |

| Operating Temperature | Up to 2500°C | Suited for extreme heat processes |

| Atmosphere Requirement | High vacuum or protective gas | Adds complexity and cost to system design |

Need a reliable heating solution for your high-temperature processes? KINTEK specializes in lab equipment and consumables, including advanced heating elements tailored for demanding environments. Whether you're working with extreme heat requirements or need guidance on material selection, our experts are here to help. Contact us today to optimize your lab's heating efficiency and achieve superior results!

Visual Guide

Related Products

- Thermally Evaporated Tungsten Wire for High Temperature Applications

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Double Plate Heating Press Mold for Lab

People Also Ask

- Where are heating elements located within a hot zone? Expert Guide on Placement for Optimal Uniformity

- What are the properties of a heating element? A Guide to Performance, Lifespan & Cost

- How does resistance create heat? Unlock the Science of Efficient Energy Conversion

- How is a ceramic heater different? Discover the Self-Regulating Safety and Efficiency

- Which high temperature furnace elements to be used in oxidizing atmosphere? MoSi2 or SiC for Superior Performance

- What is the life expectancy of a heating element? Maximize Lifespan with Proper Care

- How often do heating elements need to be replaced? Maximize Lifespan by Understanding Failure Causes

- Why are high-power electric heating rods used in in-situ catalyst reaction cells? Ensure Precision & Thermal Stability