Yes, you can apply a PVD coating to aluminum, but it is a specialized process that presents unique challenges compared to coating materials like stainless steel or titanium. The success of the coating is highly dependent on managing aluminum's low melting point and its reactive surface, which requires specific techniques and process control.

The core challenge with PVD coating aluminum is not whether it can be done, but how it must be done. Standard high-temperature PVD processes can damage the aluminum, so success hinges on using specialized low-temperature methods and meticulous surface preparation to ensure proper adhesion and preserve the integrity of the part.

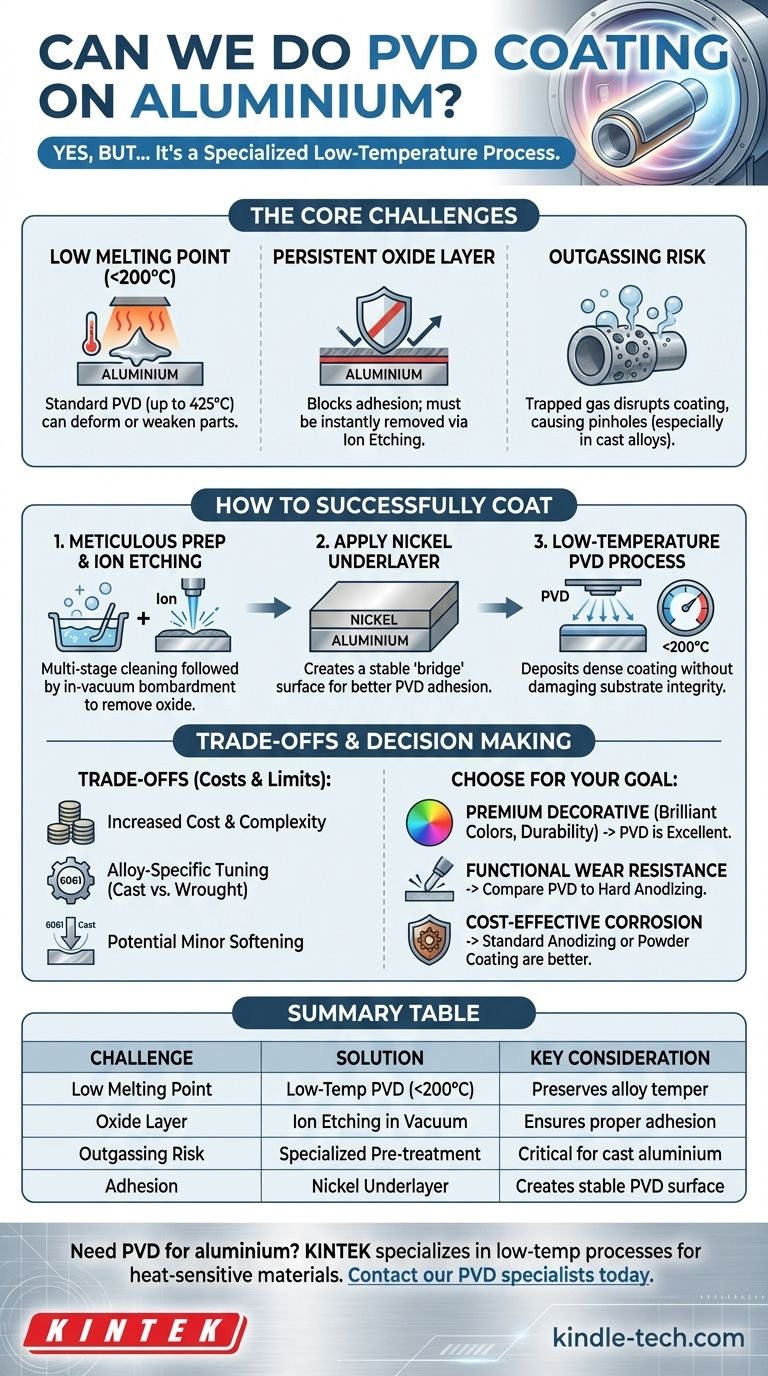

The Core Challenge: Aluminum vs. the PVD Process

To understand why coating aluminum is unique, we must first look at the inherent conflict between its properties and a standard PVD process.

The Low-Temperature Threshold

A traditional PVD process can operate at temperatures up to 425°C (800°F). Many common aluminum alloys begin to lose their temper (hardness) or even deform at temperatures well below this, starting around 200°C (400°F).

Applying a high-temperature process can weaken the structural integrity of the aluminum part, even if the coating itself is successful.

The Persistent Oxide Layer

When exposed to air, aluminum instantly forms a hard, thin, and chemically inert layer of aluminum oxide. While this layer provides excellent natural corrosion protection, it is a barrier to PVD adhesion.

This oxide layer must be completely removed immediately before the coating is deposited, a task complicated by how quickly it reforms.

The Risk of Outgassing

Aluminum alloys, particularly cast grades, can trap microscopic pockets of gas and moisture within the material. When placed in the high-vacuum environment of a PVD chamber and heated, these trapped gases escape in a process called outgassing.

This release of contaminants can disrupt the coating deposition, leading to poor adhesion, pinholes, and a failed finish.

How to Successfully Coat Aluminum

Specialized coating providers overcome these challenges using a refined, multi-step approach. The key is not to force aluminum into a standard process, but to adapt the process to the material.

Using Low-Temperature PVD Processes

The most critical adaptation is the use of low-temperature PVD technology. These advanced processes can deposit high-quality, dense coatings at temperatures below 200°C, and sometimes as low as 70°C.

This ensures the mechanical properties and dimensional stability of the aluminum substrate are preserved.

Meticulous Surface Preparation

A multi-stage cleaning process is required to remove all surface oils and contaminants. After cleaning, the parts are loaded into the PVD chamber.

Inside the vacuum, a process like ion etching (also called a "back-etch") is used. This is a crucial step where the surface of the part is bombarded with ions, effectively sandblasting it on a microscopic level to remove the native oxide layer just moments before deposition begins.

Applying an Underlayer

For maximum adhesion and durability, it is common practice to first apply an intermediate layer to the aluminum part. A layer of electroplated nickel is often used.

This nickel layer provides an ideal, stable, and dense surface that is far more receptive to the final PVD film. It acts as a bridge, creating a robust bond between the aluminum substrate and the decorative or functional topcoat.

Understanding the Trade-offs

Choosing PVD for aluminum requires acknowledging its specific limitations and costs compared to other options.

Increased Cost and Complexity

The need for low-temperature equipment, extensive pre-treatment, and a potential underlayer makes PVD coating on aluminum significantly more complex and expensive than on stainless steel. It is a premium process for a premium result.

Alloy-Specific Performance

The process must be tuned for the specific aluminum alloy. For example, cast aluminum alloys are far more prone to outgassing than wrought alloys like 6061 or 7075. You must consult with your coating partner to ensure the process is suitable for your chosen alloy.

Potential for Substrate Softening

Even with low-temperature processes, some sensitive, heat-treated aluminum alloys can experience a minor reduction in hardness. This must be evaluated if the part serves a critical structural function.

Making the Right Choice for Your Goal

PVD is a powerful tool, but it is not always the best fit for every aluminum application. Consider your primary objective to make an informed decision.

- If your primary focus is a premium decorative finish: PVD is an excellent option for achieving brilliant colors (gold, black, bronze) with high durability, provided you use a coater specializing in low-temperature processes for aluminum.

- If your primary focus is functional wear resistance: Compare the performance and cost of PVD against hard anodizing (Type III), which is a mature and highly effective surface-hardening treatment specifically for aluminum.

- If your primary focus is cost-effective corrosion protection: PVD is likely overkill. Standard anodizing (Type II) or powder coating are far more economical choices that provide excellent protection for most environments.

By understanding these factors, you can select a surface treatment that aligns perfectly with your project's performance, aesthetic, and budgetary requirements.

Summary Table:

| Challenge | Solution | Key Consideration |

|---|---|---|

| Low Melting Point | Low-Temperature PVD (<200°C) | Preserves alloy temper and integrity |

| Oxide Layer | Ion Etching in Vacuum Chamber | Ensures proper adhesion |

| Outgassing Risk | Specialized Pre-treatment | Critical for cast aluminium alloys |

| Adhesion | Nickel Underlayer | Creates stable surface for PVD film |

Need PVD coating for your aluminium components? KINTEK specializes in low-temperature PVD processes specifically designed for heat-sensitive materials like aluminium. Our expertise in surface preparation and alloy-specific coating solutions ensures durable, high-quality finishes while preserving your part's structural integrity.

Contact our PVD specialists today to discuss your aluminium coating requirements and get a tailored solution for your laboratory or manufacturing needs.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is plasma in CVD process? Lowering Deposition Temperatures for Heat-Sensitive Materials

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What materials are deposited in PECVD? Discover the Versatile Thin-Film Materials for Your Application

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method