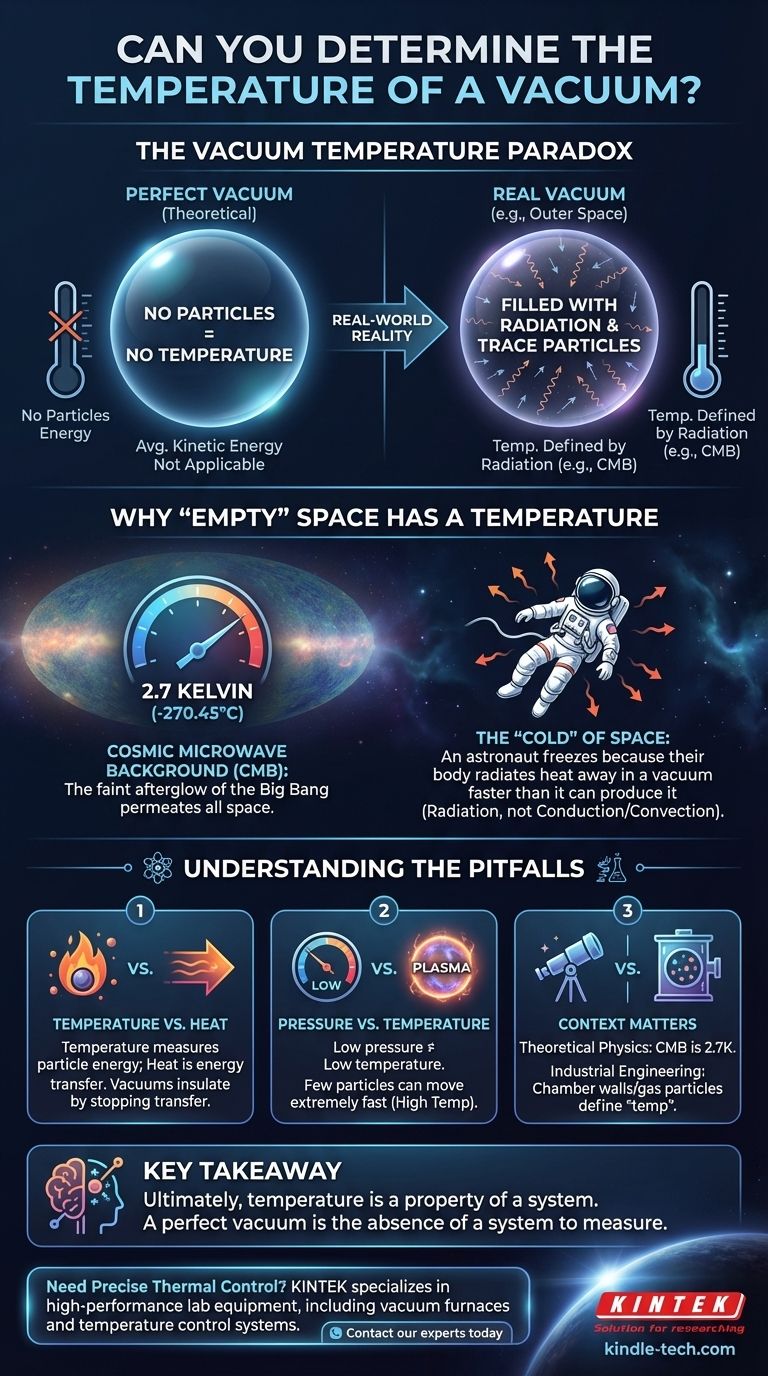

Technically, a perfect vacuum has no temperature. Temperature is a measure of the average kinetic energy of particles, and a perfect vacuum, by definition, contains no particles. However, any real-world vacuum, including the vastness of outer space, is not perfectly empty and is filled with electromagnetic radiation, which does have a measurable temperature.

The core issue is a misunderstanding of what "temperature" is. We cannot measure the temperature of nothingness; we can only measure the temperature of the particles or the energy fields that occupy a given space.

What Exactly Is Temperature?

To understand why a vacuum presents a challenge for this concept, we must first define temperature from a physics standpoint.

Temperature as Particle Motion

Temperature is a macroscopic property that emerges from the microscopic world. It represents the average kinetic energy—the motion—of the atoms and molecules within a system.

Faster-moving particles mean a higher average kinetic energy, which we perceive as a higher temperature. Slower-moving particles mean a lower temperature.

The Problem of a "Perfect" Vacuum

A perfect vacuum is a theoretical space that is entirely devoid of matter. It contains zero atoms or molecules.

If there are no particles, there is no particle motion to average. Therefore, the concept of temperature as we commonly define it simply does not apply. Asking for the temperature of a perfect vacuum is like asking for the color of the number seven; the question itself is based on a flawed premise.

Why "Empty" Space Still Has a Temperature

While a perfect vacuum has no temperature, any real vacuum is not truly empty. This is true for vacuums created in a lab and for the vastness of interstellar space.

The Role of Radiation

Any space, no matter how empty of particles, is permeated by electromagnetic radiation (photons). These photons travel through the vacuum and carry energy. An object placed in this "empty" space will absorb and emit this radiation.

Eventually, the object will reach thermal equilibrium with the radiation field. The temperature of the object at that point is effectively the temperature of the space it occupies.

The Temperature of the Universe

The dominant form of this radiation in our universe is the Cosmic Microwave Background (CMB). This is the faint afterglow of the Big Bang, a sea of photons that fills all of space.

By measuring the energy spectrum of the CMB, scientists have determined its temperature to be approximately 2.7 Kelvin (-270.45°C or -454.81°F). This is the baseline temperature of an object that is shielded from all other energy sources in the deepest parts of intergalactic space.

Understanding the Pitfalls

The relationship between a vacuum, temperature, and heat is often misunderstood. Clarifying these concepts is crucial for a correct understanding.

Conflating Temperature and Heat

Temperature is a measure of average particle energy. Heat is the transfer of that energy. A vacuum is an exceptional insulator precisely because it has almost no particles to transfer energy via conduction or convection.

This is why a thermos uses a vacuum layer to keep liquids hot or cold. It prevents heat from moving in or out.

Pressure vs. Temperature

Low pressure does not automatically mean low temperature. In a laboratory vacuum chamber, you can have a high-energy plasma—a gas of charged particles heated to thousands of degrees—while the system remains at an extremely low pressure.

This is because temperature measures the speed of the individual particles, while pressure measures the collective force they exert on the container walls. If you have very few particles (low pressure), they can still be moving very fast (high temperature).

The "Cold" of Space

An astronaut in space would freeze to death not because space is "cold" in the conventional sense, but because their body, at 37°C, radiates heat away into the near-perfect vacuum.

With no atmosphere to transfer heat back to them, their body loses energy much faster than it can produce it. They are cooling themselves down by radiating their own heat into the void.

Making the Right Choice for Your Goal

How you think about the temperature of a vacuum depends entirely on your context.

- If your primary focus is theoretical physics: The temperature of "empty" space is defined by the Cosmic Microwave Background, which is 2.7 Kelvin.

- If your primary focus is industrial engineering: The "temperature" in your vacuum system is the temperature of the few remaining gas particles or, more practically, the temperature of the chamber walls.

- If your primary focus is general understanding: A vacuum itself doesn't have a temperature, but anything within that vacuum—whether it's an object or an energy field—does.

Ultimately, temperature is a property of a system, and a perfect vacuum is the absence of a system to measure.

Summary Table:

| Concept | Description | Key Takeaway |

|---|---|---|

| Perfect Vacuum | A theoretical space with zero particles. | Has no temperature, as temperature requires particles. |

| Real Vacuum | Contains trace particles and radiation. | Temperature is defined by the dominant energy field (e.g., CMB at 2.7 K). |

| Heat vs. Temperature | Temperature measures particle energy; heat is energy transfer. | A vacuum is a great insulator, preventing heat transfer via conduction/convection. |

Need precise thermal control for your vacuum processes? KINTEK specializes in high-performance lab equipment, including vacuum furnaces and temperature control systems. Our solutions ensure accuracy and reliability for your most demanding applications. Contact our experts today to discuss how we can optimize your laboratory's capabilities.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

People Also Ask

- What is the strength of brazing aluminum? Achieve Robust, Leak-Tight Assemblies

- What is a high temperature furnace? A Guide to Precision Heat Treatment & Sintering

- What is the process of a vacuum furnace? Achieve Superior Material Purity and Performance

- Does carburizing harden steel? The Critical Role of Carburizing in Case Hardening

- What role does a high-temperature furnace play in Inconel 718 homogenization? Ensure Microstructural Precision

- Should I use flux when brazing aluminum? The Critical Role of Flux in Achieving a Strong Bond

- What is a vacuum heat treatment furnace? Achieve Unmatched Purity and Control

- What is the critical role of a vacuum drying oven in the preparation of LATP-Li3InCl6? Optimize Your Solid Electrolytes