Absolutely. Overheating a crucible is not only possible, but it is a primary cause of premature failure and a significant safety hazard in any casting or foundry operation. The consequences range from accelerated wear that shortens the crucible's lifespan to catastrophic failure, risking equipment damage and serious personal injury.

The core issue is rarely about a single instance of high heat. True damage comes from thermal shock—heating or cooling too rapidly—and from prolonged exposure to temperatures that degrade the crucible's structural material, even if below its theoretical melting point.

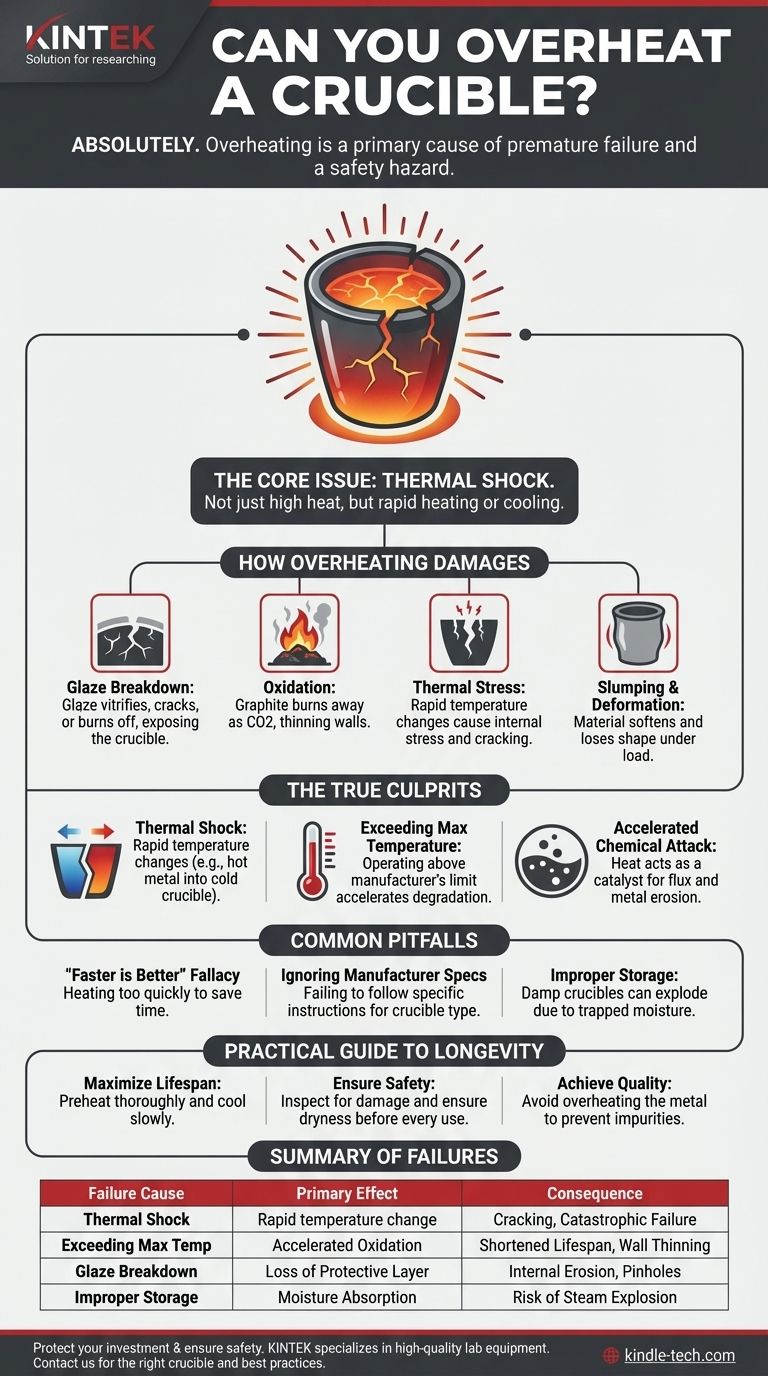

How Overheating Damages a Crucible

Understanding the failure mechanism is the first step toward prevention. When a crucible is pushed beyond its operational limits, several destructive processes begin simultaneously.

Breakdown of the Protective Glaze

Most silicon carbide and clay-graphite crucibles have a protective glaze. This layer is the first line of defense against oxidation.

When overheated, this glaze can vitrify, crack, or burn off entirely, exposing the raw crucible material to the harsh furnace atmosphere.

Oxidation and Material Degradation

Once the glaze is compromised, oxygen can attack the crucible itself. For graphite-based crucibles, this means the graphite literally burns away, turning into CO2 gas.

This process, called oxidation, creates pinholes, reduces wall thickness, and severely weakens the crucible's structure from the outside in.

Cracking from Thermal Stress

Every material expands when heated and contracts when cooled. If this happens too quickly, different parts of the crucible change temperature at different rates, creating immense internal stress.

This thermal stress is the primary cause of cracking. A crack can form in an instant and may lead to a complete failure on the next use.

Slumping and Deformation

For certain types of crucibles, particularly clay-graphite, extreme heat can cause the material to soften and lose its shape.

The crucible may begin to slump or bulge under the weight of the molten metal, making it unstable and unsafe to handle.

The True Culprits: More Than Just High Temperature

Thinking that damage only occurs by setting the furnace too high is a dangerous oversimplification. The real causes are often more nuanced.

The Primary Danger: Thermal Shock

Thermal shock is the most common and destructive force. It occurs from a rapid change in temperature, not just high temperature itself.

Think of pouring hot water into a cold, thick glass—it shatters. A crucible experiences the same stress when placed into a preheated furnace or when cooled too quickly in open air.

Exceeding Maximum Service Temperature

Every crucible has a maximum service temperature specified by the manufacturer. This is the absolute ceiling for its intended use.

Operating above this temperature, even for short periods, drastically accelerates oxidation and chemical wear, significantly shortening the crucible's life. Always consult the datasheet for your specific model.

Accelerated Chemical Attack

Heat acts as a catalyst for chemical reactions. Aggressive fluxes or reactive metals (like certain aluminum alloys) will attack and erode the crucible wall much faster at excessive temperatures.

This internal erosion weakens the crucible from the inside, a type of damage that can be difficult to detect until it's too late.

Common Pitfalls That Lead to Failure

Most crucible failures can be traced back to procedural errors rather than a faulty product. Avoiding these common mistakes is critical for safe and efficient operation.

The "Faster is Better" Fallacy

In a production environment, time is money. This creates a temptation to heat the melt as quickly as possible. This is the single most common cause of thermal shock.

A controlled, gradual pre-heating and a slow ramp-up to the target temperature are non-negotiable for crucible longevity.

Ignoring Manufacturer Specifications

A silicon carbide crucible has very different heating and storage requirements than a pure graphite or a clay-graphite crucible.

Failing to read and follow the specific instructions for your crucible type is a direct path to premature failure.

Improper Storage and Handling

Crucibles can absorb moisture from the atmosphere. If a damp crucible is placed into a furnace, the trapped moisture rapidly turns to steam, creating immense pressure that can cause it to explode.

Always store crucibles in a warm, dry place. A dedicated holding oven is the industry best practice.

A Practical Guide to Crucible Longevity

Use these guidelines to tailor your procedures to your primary objective.

- If your primary focus is maximizing crucible lifespan: Always preheat your crucible thoroughly before the first use and before every subsequent use, and allow it to cool slowly inside the furnace after a pour.

- If your primary focus is operational safety: Visually inspect your crucible for cracks, pinholes, or excessive wear before every single use, and ensure it is completely dry before charging it into the furnace.

- If your primary focus is achieving the highest quality melt: Avoid overheating your metal, as this not only damages the crucible but can also introduce impurities and gas porosity into your casting.

Mastering these principles transforms your crucible from a simple consumable into a reliable, long-lasting tool.

Summary Table:

| Failure Cause | Primary Effect | Consequence |

|---|---|---|

| Thermal Shock | Rapid temperature change causes stress | Cracking, catastrophic failure |

| Exceeding Max Temperature | Accelerated oxidation & material degradation | Shortened lifespan, wall thinning |

| Glaze Breakdown | Loss of protective layer | Internal erosion, pinholes |

| Improper Storage | Moisture absorption | Risk of steam explosion on heating |

Protect your investment and ensure operator safety. Proper crucible use is critical for efficient and safe lab operations. KINTEK specializes in high-quality lab equipment and consumables, including crucibles designed for durability and performance. Our experts can help you select the right crucible for your application and provide guidance on best practices to maximize its lifespan. Contact our team today to discuss your laboratory needs and ensure your processes are both safe and efficient.

Visual Guide

Related Products

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

People Also Ask

- What role do high-temperature ceramic crucibles play in the synthesis of Na2Ni2TeO6 and Na2Zn2TeO6 at 850 Celsius?

- Why are alumina crucibles used for Al-LLZ sintering? The Secret to Stable Cubic Phase Lithium Garnet

- What are the disadvantages of crucible furnace? Understanding the Trade-offs in Metal Melting

- How long will a crucible last? Maximize Its Lifespan from 15 to 100+ Heats

- What materials are crucibles made of? A Guide to Choosing the Right Crucible Material

- Why are alumina crucibles and mother powder used for LLZO sintering? Master Lithium Stability in Solid-State Ceramics

- Which crucible is better? Find the Right Crucible for Your Specific Application

- What are the best crucibles? Find the Perfect Crucible for Your Metal & Furnace