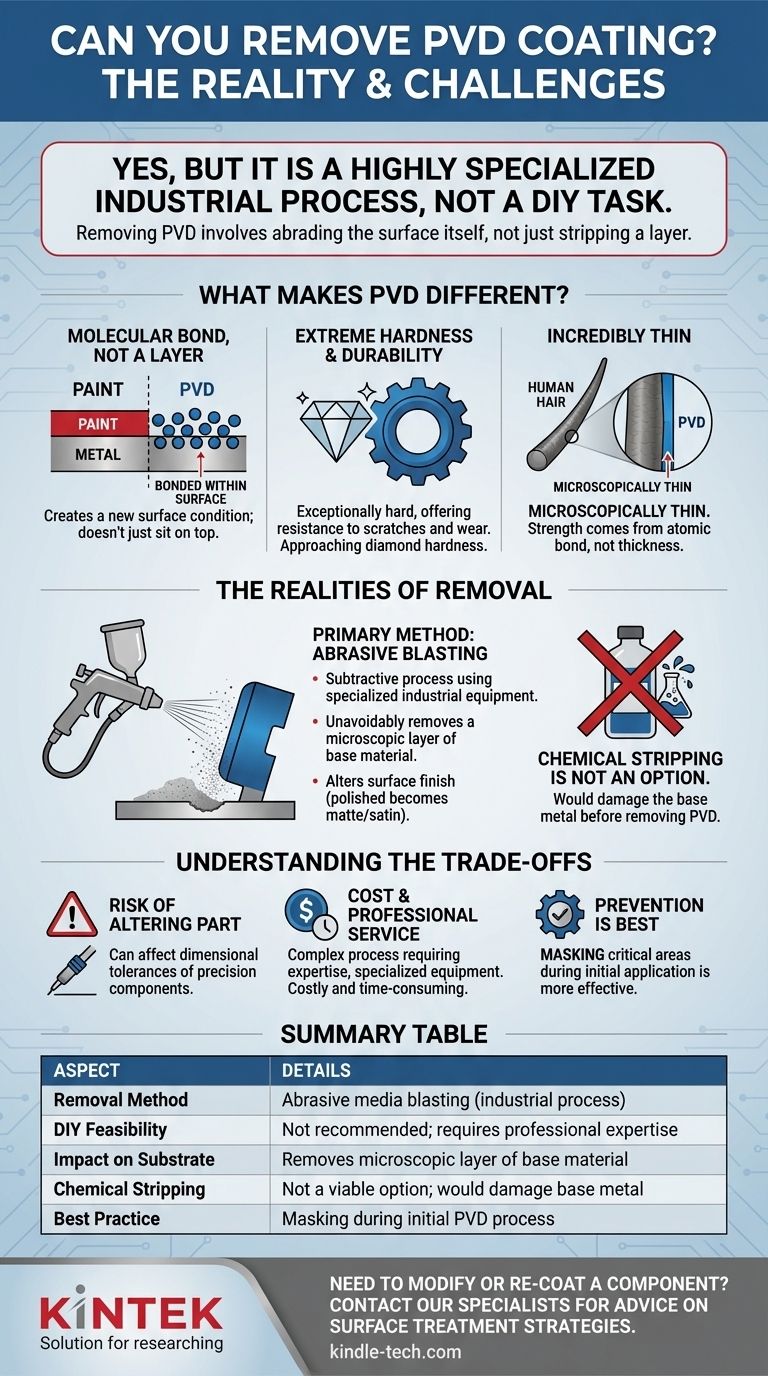

Yes, a PVD coating can be removed, but it is a highly specialized industrial process, not a simple stripping task you can do at home. Because PVD integrates with the metal at a molecular level rather than sitting on top like paint, removing it involves abrading the surface of the object itself.

The core challenge in removing a Physical Vapor Deposition (PVD) coating is that it isn't a separate layer. It is an extremely hard, thin surface modification bonded to the substrate, meaning removal requires physically grinding away the very surface of the part.

What Makes PVD Different from a Standard Coating?

To understand why removal is so difficult, you must first understand why PVD is so effective. Its strength comes from its unique application process and fundamental structure, which is completely different from traditional plating or painting.

It's a Molecular Bond, Not a Layer

PVD is not a coating in the traditional sense. It does not add a substantial, distinct layer to the material.

Instead, the process bonds new material within the surface of the substrate at the micron level. This creates a new surface condition, fundamentally changing the physical properties of the metal's outermost layer.

Think of it as a stain that soaks into wood, rather than a layer of paint that sits on top of it. You can't just peel it off.

Extreme Hardness and Durability

PVD coatings are exceptionally hard—in some cases, approaching the hardness of a diamond.

This is what gives PVD-coated items their signature resistance to scratches and wear. This same property, however, makes them incredibly difficult to remove through conventional means.

It's Incredibly Thin

While exceptionally hard, PVD coatings are also microscopically thin.

Their durability does not come from thickness, but from the strength of the atomic bond they form with the substrate. This thinness means you can't simply chip it away; you have to meticulously wear it down.

The Realities of PVD Coating Removal

Because PVD coatings are chemically inert and physically bonded to the substrate, they cannot be dissolved or peeled. Removal is a subtractive process that must be performed with specialized industrial equipment.

The Primary Method: Abrasive Blasting

The most common method for removing a PVD coating is abrasive media blasting.

This involves bombarding the surface with a high-pressure stream of fine, hard particles (like aluminum oxide) to slowly and evenly grind away the PVD layer. This is a precise process that requires professional expertise to avoid damaging the part.

The Impact on the Substrate

Removing the PVD coating unavoidably removes a microscopic layer of the base material.

This process will alter the original surface finish. A polished, mirror-like surface will almost certainly become a matte or satin finish after the abrasive blasting required to strip the PVD. The part will need to be re-polished and refinished if the original look is desired.

Chemical Stripping Is Not an Option

The properties that make PVD resistant to corrosion and tarnish also make it almost completely immune to chemical strippers.

Any acid or chemical agent powerful enough to attack the PVD coating would be so aggressive that it would severely damage or destroy the underlying base metal long before the coating is fully removed.

Understanding the Trade-offs

Deciding to remove a PVD coating is a significant step with permanent consequences. It is a corrective measure, not a simple cosmetic change.

Risk of Altering the Part

The abrasive removal process is aggressive. For parts with very tight dimensional tolerances, such as watch components or precision tools, removing the PVD could alter their dimensions enough to affect performance.

Cost and Professional Service

PVD removal is not a DIY task. It must be done by a coating specialist with the correct blasting equipment and experience. This makes it a costly and time-consuming service compared to the part's original value.

Prevention Is the Best Strategy

In manufacturing, the ideal approach is masking. Certain areas of a part can be covered to prevent the PVD from being deposited on them in the first place. This is a far more controlled and effective strategy than attempting removal after the fact.

Making the Right Choice for Your Goal

Before proceeding with removal, clarify your objective. The "why" behind the removal dictates whether it's a worthwhile endeavor.

- If your PVD coating is simply worn or scratched: Consider that attempting removal will fundamentally change the entire surface finish, which may be a more significant cosmetic issue than the original scratches.

- If you need to change the color or finish: Be prepared for a multi-step process. Removing the old PVD is just the first step, which must be followed by refinishing the base metal and then applying the new coating.

- If you are designing a new part: Specify masking during the PVD process to protect critical areas or surfaces. Planning ahead is vastly more effective than correcting afterward.

Understanding that PVD is a surface modification, not a simple layer, is the key to managing its life cycle effectively.

Summary Table:

| Aspect | Details |

|---|---|

| Removal Method | Abrasive media blasting (industrial process) |

| DIY Feasibility | Not recommended; requires professional expertise |

| Impact on Substrate | Removes a microscopic layer of the base material |

| Chemical Stripping | Not a viable option; would damage the base metal |

| Best Practice | Masking during the initial PVD coating process |

Need to modify or re-coat a precision component? The PVD removal process is complex and requires specialized equipment to avoid damaging your valuable lab equipment parts. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can advise on the best surface treatment strategies for your specific application, whether it's for recoating, repair, or R&D. Contact our specialists today via our contact form to discuss your project and ensure optimal results.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- CVD Diamond Optical Windows for Lab Applications

- Isostatic Molding Pressing Molds for Lab

People Also Ask

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating