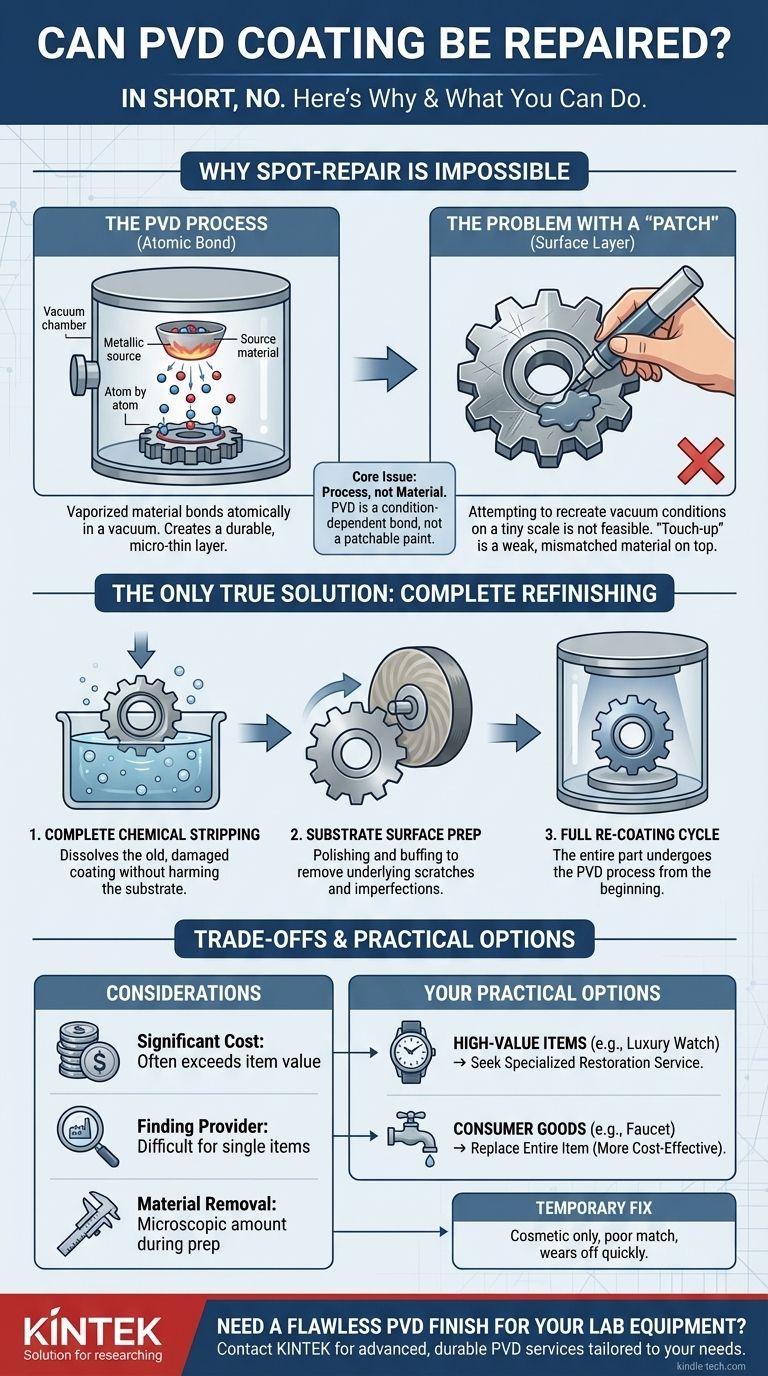

In short, no. You cannot repair a Physical Vapor Deposition (PVD) coating in the traditional sense of a spot-fix or touch-up. The very nature of the PVD process, which involves bonding a thin film of material to a substrate at an atomic level within a vacuum, makes localized repairs impossible. The only true method for restoration is to completely strip the original coating and re-coat the entire part.

The core issue is one of process, not material. PVD coatings are not like paint that can be patched; they are a highly-adhered, micro-thin surface created under specific vacuum conditions. A repair would require recreating those conditions on a tiny scale, which is not feasible.

Why PVD Can't Be Spot-Repaired

To understand the challenge of repair, you must first understand how the coating is applied. This context clarifies why a simple touch-up is not a viable option.

The PVD Application Process

Physical Vapor Deposition is a vacuum-coating process. A solid source material (like titanium or zirconium) is vaporized and then deposits, atom by atom, onto the surface of the object being coated.

This process creates an incredibly thin—often only a few microns thick—but extremely hard and durable layer that is atomically bonded to the substrate material.

The Problem with a "Patch"

A true PVD repair would require isolating the damaged area and perfectly recreating the vacuum, temperature, and atomic deposition process on that spot alone. This is technologically impossible outside of highly specialized laboratory settings.

Any attempt to use a "touch-up" paint or marker is simply applying a completely different, and much weaker, material on top of the scratch. It will not match the color, sheen, or extreme durability of the original PVD finish.

Damage Often Includes the Substrate

A scratch or ding that is significant enough to be highly visible has likely gone through the thin PVD layer and damaged the underlying metal (the substrate).

Even if you could re-coat the object, that underlying scratch in the base material would still be visible. Proper restoration requires addressing the substrate first.

The Correct Process: Stripping and Re-coating

The professional solution for a damaged PVD item is not a repair but a complete refinishing. This is a multi-step industrial process.

Step 1: Complete Chemical Stripping

The first step is to completely remove the old, damaged PVD coating. This is typically done using a specialized chemical stripping process that dissolves the coating without damaging the substrate material beneath.

Step 2: Substrate Surface Preparation

Once the part is stripped bare, the underlying material must be prepared. This involves polishing and buffing out any scratches, dings, or imperfections in the substrate itself.

The final PVD finish is only as good as the surface it is applied to. A mirror-polish PVD finish requires a perfect mirror-polish on the substrate beforehand.

Step 3: The Full Re-coating Cycle

After preparation, the item is cleaned and placed back into a PVD chamber. The entire coating process is run again from the beginning, applying a fresh, flawless, and uniform coating over the entire part.

Understanding the Trade-offs

While refinishing is possible, it comes with practical considerations that often make it unfeasible for common items.

Significant Cost

Stripping, polishing, and re-coating a single item can be very expensive. The labor for surface preparation and the cost of running a PVD chamber cycle often make it more costly than the original item, especially for consumer goods.

Finding a Willing Provider

Many PVD coating facilities are geared toward high-volume industrial production runs. Finding a company that is willing to process a single, small part—like a watch case or a faucet—can be difficult and expensive.

Material Removal

The process of stripping and re-polishing the substrate inherently removes a microscopic amount of material. For most objects, this is completely irrelevant, but for high-precision components with tight tolerances, it is a factor to consider.

What Are Your Practical Options?

When faced with a damaged PVD-coated item, your decision should be based on the item's value and your expectations.

- If your item is high-value (e.g., a luxury watch, custom part): Seek a specialized PVD coating or watch restoration service that can professionally strip, polish, and re-coat the item to its original specification.

- If your item is a standard consumer good (e.g., a faucet, door handle, kitchen hardware): It is almost always more practical and cost-effective to replace the item entirely.

- If you are looking for a temporary cosmetic fix: Understand that any touch-up paint will be a poor match for the durability and appearance of PVD and will likely wear off quickly.

Ultimately, understanding that PVD is an advanced industrial finish, not a simple layer of paint, is the key to managing expectations for its repair.

Summary Table:

| Consideration | Key Takeaway |

|---|---|

| Spot Repair | Technologically impossible due to vacuum process requirements. |

| True Restoration | Requires complete stripping, substrate polishing, and full re-coating. |

| Cost | Often exceeds the value of standard consumer goods. |

| Practicality | Viable for high-value items like luxury watches; replacement is better for common goods. |

Need a Flawless PVD Finish for Your Lab Equipment?

At KINTEK, we understand that precision and durability are non-negotiable in a laboratory environment. Our advanced PVD coating services are tailored for lab equipment and consumables, ensuring superior wear resistance, chemical inertness, and long-lasting performance.

Whether you require new custom-coated components or are exploring refinishing options for high-value items, our expertise ensures a perfect, durable finish that meets the rigorous demands of your work.

Let KINTEK enhance your lab's capabilities with a finish built to last. Contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings