Yes, you can scratch a PVD coating, but it is exceptionally difficult. While not invincible, Physical Vapor Deposition (PVD) creates a surface finish that is molecularly bonded to the base metal and possesses extreme hardness. This makes it vastly more resistant to scratches and wear than traditional plating, painting, or powder coating.

The true durability of a PVD coating is a function of two factors: the hardness of the coating itself and the strength of the underlying metal it's applied to. Thinking of it as a complete system is the key to understanding its limits.

What Makes PVD Scratch-Resistant?

The remarkable durability of PVD comes from the nature of the application process itself. It is not simply a layer of paint; it is an advanced finish integrated with the material.

A Matter of Hardness

At its core, a scratch is created when one object is significantly harder than another. PVD coatings are exceptionally hard—often harder than the steel tools or common abrasive materials encountered in daily life.

This inherent hardness is the coating's primary defense against the fine scratches and scuffs that would quickly mar a lesser finish.

The Molecular Bond

Unlike plating, which sits on top of a material, PVD is molecularly bonded to the substrate in a high-vacuum environment. The coating material becomes an integral part of the surface.

This prevents the chipping and flaking commonly seen with plated or painted finishes, as there is no clear boundary line for damage to propagate along.

The Role of the Substrate

The material underneath the PVD coating, known as the substrate, is a critical and often overlooked factor. The reference to coating properties being "determined by the underlying substrate" is the most important concept to grasp.

A hard PVD coating on a soft metal can be compromised if the base metal itself is dented or deformed.

How PVD Coatings Actually Fail

While highly resistant, PVD is not indestructible. Understanding its failure modes helps set realistic expectations for its longevity under different conditions.

Abrasive Scratches

To create a classic scratch, you need a material that is harder than the PVD coating. This is rare in normal use, but possible. Materials like diamond, sapphire crystal, or even coarse ceramic can be hard enough to visibly scratch a PVD surface. Sand or granite particles can also cause abrasion over time.

Impact and Deformation

This is the most common cause of visible damage. Imagine a thin layer of hard ice over soft mud. If you press on the ice, it won't scratch, but it will crack and break because the mud underneath gives way.

Similarly, if a PVD-coated object is dropped or struck, the softer substrate (like stainless steel) may dent. This deformation of the base metal can cause the thin, rigid PVD layer to crack or chip at the point of impact.

Gradual Wear

On very high-contact points, like the sharp edges of a watch clasp or the tip of a tool, millions of microscopic abrasions over many years can eventually wear down the finish. This typically appears as a slight burnishing or fading of the color rather than a distinct scratch.

Understanding the Trade-offs

PVD offers incredible performance, but it's essential to recognize its limitations to make an informed decision.

Not All PVD is Created Equal

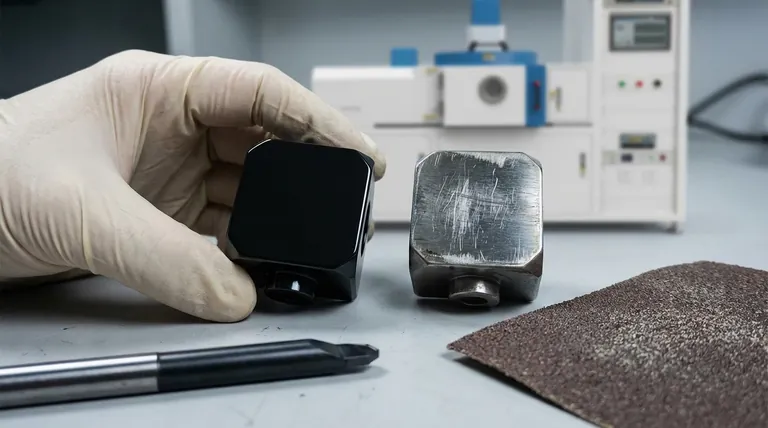

"PVD" is a process, not a single material. Different coating compounds like Titanium Nitride (TiN, often gold-colored) or Diamond-Like Carbon (DLC, often black) have different levels of hardness and lubricity. DLC is generally considered one of the hardest and most durable options.

The Substrate is Crucial

A PVD finish on hardened tool steel will be vastly more durable in practice than the exact same coating applied to softer aluminum or brass. The stronger substrate provides the necessary support to prevent dents and deformation, thereby protecting the PVD layer.

Scratches are Permanent

Perhaps the most significant trade-off is that you cannot "buff out" a scratch on a PVD coating. If the coating is breached, the only way to repair it is to strip the entire object and have it professionally re-coated, which is often impractical or impossible.

Making the Right Choice for Your Goal

Your satisfaction with a PVD-coated product depends entirely on aligning its capabilities with your intended use.

- If your primary focus is daily-use durability (e.g., a watch, faucet, or tool): Prioritize a PVD finish on a hard substrate like stainless steel or titanium.

- If your primary focus is aesthetic appeal on a low-contact item: The substrate material is less critical, as the risk of significant impact is low.

- If you are concerned about potential damage: Accept that while PVD is the market leader in resilience, a deep scratch is permanent and cannot be polished away.

By understanding PVD as a complete system of coating and substrate, you can accurately judge its durability for your specific needs.

Summary Table:

| Factor | Impact on Scratch Resistance |

|---|---|

| Coating Hardness | High hardness (e.g., DLC) resists abrasion from most materials. |

| Molecular Bond | Strong bond to substrate prevents chipping and flaking. |

| Substrate Strength | A hard underlying metal (e.g., steel) supports the coating against impact. |

| Common Threats | Diamond, sapphire, or impact that deforms the substrate can cause damage. |

Need a durable, scratch-resistant finish for your lab equipment or components? KINTEK specializes in advanced coating solutions, including PVD, to protect your laboratory tools and consumables from daily wear and tear. Our expertise ensures a molecularly bonded, hard coating that extends the life of your equipment. Contact our experts today to discuss how we can enhance your lab's performance and durability!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Custom CVD Diamond Coating for Lab Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Cold Trap Direct Cold Trap Chiller

- Isostatic Molding Pressing Molds for Lab

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating