In a hydraulic system, the fluid itself is the lubricant. This is a fundamental design principle. Hydraulic systems do not require a separate lubricating oil because the hydraulic fluid is engineered as a multi-function component, responsible for not only transmitting power but also for protecting the system's internal parts from wear.

The core misunderstanding is thinking of lubrication as a separate requirement. The right perspective is to see the hydraulic fluid as a complex, engineered component that performs several critical jobs simultaneously, with lubrication being one of its most important.

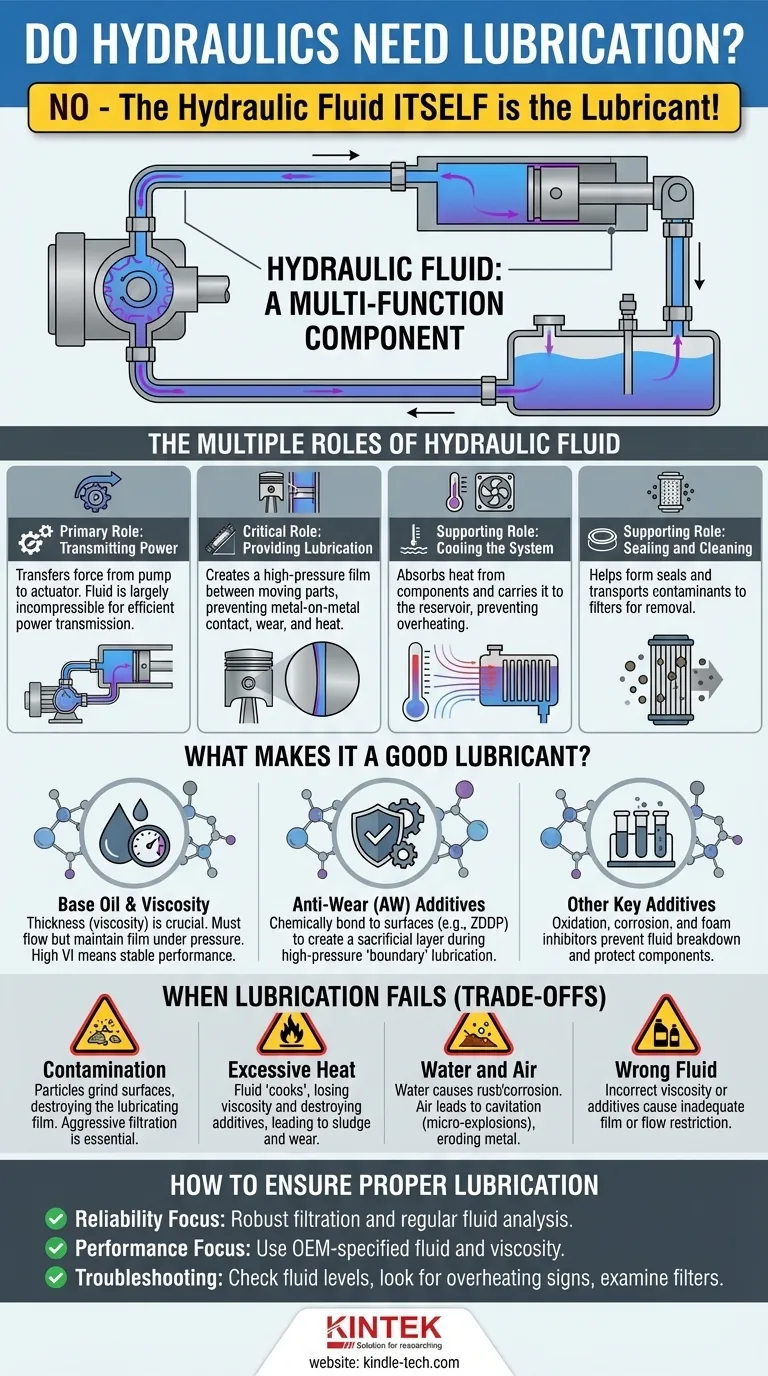

The Multiple Roles of Hydraulic Fluid

Hydraulic fluid is often called the "lifeblood" of the system for good reason. It does far more than just push a cylinder. Understanding its multiple functions is key to appreciating why separate lubrication isn't necessary.

Primary Role: Transmitting Power

The most obvious job of hydraulic fluid is to transmit force from one point to another. Because liquids are largely incompressible, pressure applied at one end of a system (by a pump) is instantly transferred to the other end (to an actuator or motor).

Critical Role: Providing Lubrication

This is the answer to your core question. The fluid creates a high-pressure film between moving metal parts, such as between a piston and its cylinder wall or in the tight tolerances of a pump. This film prevents direct metal-on-metal contact, which would cause catastrophic wear and heat generation.

Supporting Role: Cooling the System

As the fluid circulates, it absorbs heat from components like pumps and motors and carries it back to the reservoir, which often acts as a heat exchanger. This constant heat transfer is essential for preventing overheating and fluid degradation.

Supporting Role: Sealing and Cleaning

The fluid helps form seals within components and also acts as a transport medium. It carries away contaminants—like tiny metal particles from wear or dirt that has ingressed—and moves them to the system's filters for removal.

What Makes Hydraulic Fluid a Good Lubricant?

Not just any oil can do this job. Hydraulic fluids are highly engineered with a precise balance of base oil and chemical additives to meet the extreme demands of the system.

The Foundation: Base Oil and Viscosity

The viscosity—or thickness—of the fluid is its most important property. It must be thin enough to flow efficiently but thick enough to maintain a protective lubricating film under immense pressure and heat. The Viscosity Index (VI) measures how much the viscosity changes with temperature; a high VI means the fluid performs predictably across a wide operating range.

The Protector: Anti-Wear (AW) Additives

Under the highest pressures, the fluid film can momentarily collapse. Anti-wear (AW) additives, such as Zinc Dialkyl Dithiophosphate (ZDDP), are designed to handle this. They chemically bond to metal surfaces, creating a sacrificial layer that shears off instead of the component's base metal, providing critical protection during these "boundary lubrication" events.

The Stabilizers: Other Key Additives

Hydraulic fluids also contain a suite of other additives, including oxidation inhibitors to prevent the fluid from breaking down at high temperatures, corrosion inhibitors to protect metal surfaces from water, and foam inhibitors to prevent air bubbles from degrading performance and lubrication.

Understanding the Trade-offs: When Lubrication Fails

Proper lubrication isn't automatic; it depends entirely on maintaining the health of the hydraulic fluid. Failure to do so is the leading cause of hydraulic system malfunction.

The #1 Enemy: Contamination

Particulate contamination (dirt, dust, metal flakes) is like sand in your engine. These particles get trapped in the tight clearances between moving parts, grinding away at surfaces and destroying the very lubricating film that is meant to protect them. Aggressive filtration is not optional; it is essential.

The Silent Killer: Excessive Heat

Operating a system above its designed temperature range causes the hydraulic fluid to "cook." This thermal breakdown permanently lowers the fluid's viscosity and destroys its protective additives. The result is a fluid that can no longer lubricate, leading to accelerated wear and the formation of sludge and varnish that clog the system.

The Corruptors: Water and Air

Water in hydraulic fluid promotes rust and corrosion and can react with additives, reducing lubricity. Air can become entrained in the fluid, and when compressed and decompressed rapidly (a process called cavitation), it creates micro-explosions that erode and pit metal surfaces in pumps and motors.

The Simple Mistake: Using the Wrong Fluid

Using a fluid with the wrong viscosity or additive package is a direct path to failure. A fluid that is too thin won't provide an adequate film, while a fluid that is too thick will cause flow restriction, heat generation, and wasted energy.

How to Ensure Proper Lubrication in Your System

Protecting your hydraulic system is a matter of proactive maintenance focused on the health of the fluid.

- If your primary focus is reliability: Prioritize a robust filtration program and regular fluid analysis to monitor for contaminants, water content, and fluid degradation.

- If your primary focus is performance and efficiency: Always use the exact fluid type and viscosity grade specified by the original equipment manufacturer (OEM).

- If your primary focus is troubleshooting a problem: Start by checking fluid levels, looking for signs of overheating (discolored fluid, burnt smell), and examining filters for excessive debris.

Treating your hydraulic fluid as the critical machine component it is is the most effective way to guarantee system longevity and performance.

Summary Table:

| Function | Why It Matters | Key Takeaway |

|---|---|---|

| Power Transmission | Transfers force efficiently through incompressible fluid. | The primary, obvious role. |

| Lubrication | Creates a protective film to prevent metal-on-metal wear. | Answers the core question; no separate oil needed. |

| Cooling | Absorbs and carries heat away from critical components. | Prevents overheating and fluid degradation. |

| Sealing & Cleaning | Helps form seals and carries contaminants to filters. | Maintains system cleanliness and integrity. |

Ensure your hydraulic systems run with maximum reliability and efficiency. The right fluid and maintenance practices are critical for preventing costly downtime and repairs. KINTEK specializes in laboratory equipment and consumables, providing the high-quality hydraulic fluids and filtration systems your lab needs to protect its investments. Contact our experts today to discuss your specific requirements and keep your equipment running smoothly.

Visual Guide

Related Products

- Manual Lab Heat Press

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- 10L Chilling Circulator Cooling Water Bath Low Temperature Constant Temperature Reaction Bath

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What is the conclusion of a hydraulic press? Unmatched Force for Industrial Applications

- What are the failures of a hydraulic press? Prevent Downtime and Ensure Safety in Your Lab

- What is an automatic press machine? High-Precision Force for Modern Manufacturing

- What does a manual press do? Understand the Two Key Types for Your Lab or Industrial Needs

- What is the construction of a hydraulic press based on? Unlocking the Power of Pascal's Law