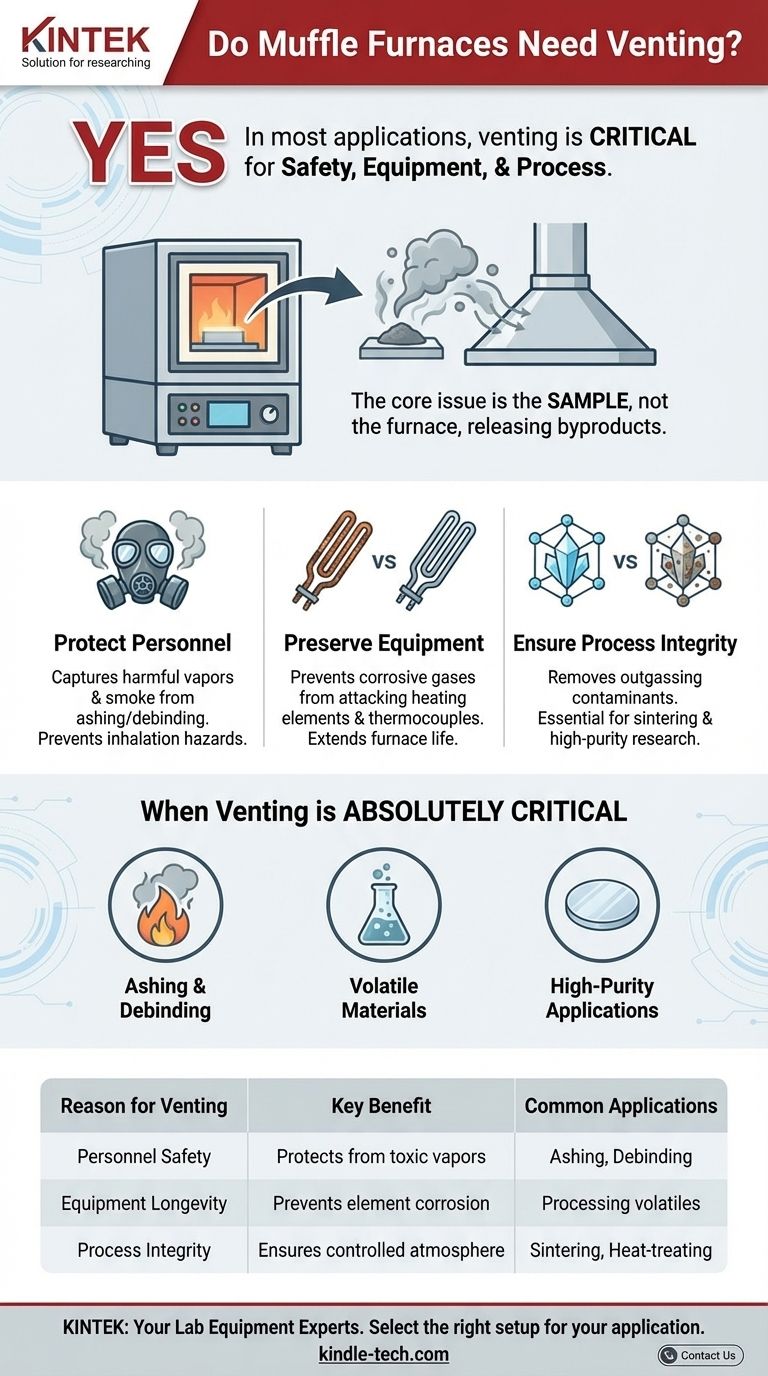

In most laboratory and industrial applications, yes, a muffle furnace must be vented. While modern electric furnaces don't produce combustion byproducts from their heating method, the materials being processed inside often release gases, vapors, or fumes. Proper venting is critical not only for operator safety but also for protecting the furnace's internal components from corrosion and ensuring the purity of your process.

The core issue is not the furnace itself, but the sample being heated. Venting is a critical control measure to manage the byproducts released from your material at high temperatures, safeguarding both personnel and the equipment.

The Primary Reasons for Venting a Muffle Furnace

Understanding why venting is necessary allows you to assess the risk for your specific application. The requirements stem from three distinct needs: personnel safety, equipment longevity, and process integrity.

Protecting Personnel from Harmful Vapors

Many high-temperature applications, such as ashing samples or debinding parts, are designed to burn off organic material. This process explicitly creates smoke, vapors, and gases that can be toxic, corrosive, or simply hazardous to inhale.

A proper ventilation system captures these emissions at the source and directs them safely out of the laboratory or facility.

Preserving the Furnace's Heating Elements

The byproducts released from a heated sample don't just pose a risk to people; they can also damage the furnace itself.

Corrosive gases can aggressively attack the furnace's heating elements and thermocouple. As noted in technical documentation, a vent directs these damaging vapors away, preventing rust and oxidation that significantly shorten the lifespan of these critical components.

Ensuring Process Integrity

In materials research, such as sintering or heat-treating, the atmospheric conditions inside the furnace are paramount.

Trapped gases or contaminants released from the sample can interfere with the process, altering the final properties of the material. Venting ensures these unwanted byproducts are removed, maintaining a controlled environment for reliable and repeatable results.

When Venting is Absolutely Critical

While venting is almost always a best practice, it becomes non-negotiable for certain common muffle furnace applications. If your work involves any of the following, a robust ventilation plan is mandatory.

Ashing and Debinding

These processes are designed to combust material, producing significant smoke and fumes. Failing to vent during ashing or binder burnout is a major safety hazard and will quickly foul the furnace chamber and corrode its elements.

Treating Materials with Volatile Components

Any material that outgases when heated requires ventilation. This includes polymers, materials with oils or cutting fluids, or samples containing sulphates or chlorides which can release highly corrosive gases.

High-Purity Applications

For processes in metallurgy or ceramics research where even trace contaminants can ruin a sample, venting is essential. It removes any atmospheric gases that are driven out of the material as it heats, ensuring the resulting product meets its required specifications.

Understanding the Trade-offs

While essential, the act of venting does have implications for the furnace's operation that you should be aware of.

Temperature Uniformity

An open vent provides an escape route for heat. This can create a minor temperature gradient inside the chamber and may slightly increase the energy required to maintain a set point. However, modern furnaces with programmable controls are designed to compensate for this effectively.

Inert Atmosphere vs. Air

Venting is primarily for processes occurring in a standard air atmosphere. If your application requires a controlled inert atmosphere (e.g., using argon or nitrogen), you will use a sealed system with gas inlets and outlets instead of a simple vent to the outside air.

The Source of Contaminants

It is crucial to remember that modern electric muffle furnaces heat via conduction, convection, or radiation. They do not burn fuel and therefore do not create combustion byproducts on their own. The need for venting is driven entirely by the sample placed inside.

Making the Right Decision for Your Application

Choosing your ventilation strategy depends entirely on the materials you are processing and your desired outcome.

- If your primary focus is safety during ashing or debinding: Venting is mandatory and should be routed directly into an exhaust hood or fume extraction system.

- If your primary focus is equipment longevity when heating potentially corrosive materials: A vent is a simple and effective way to protect your investment in the furnace's heating elements.

- If your primary focus is process purity for materials research: Venting is a critical step to remove unwanted outgassing and ensure the integrity of your results.

Ultimately, proper venting is a fundamental aspect of operating a muffle furnace safely and effectively.

Summary Table:

| Reason for Venting | Key Benefit | Common Applications |

|---|---|---|

| Personnel Safety | Protects from toxic/corrosive vapors | Ashing, Debinding |

| Equipment Longevity | Prevents corrosion of heating elements | Processing volatile materials |

| Process Integrity | Ensures controlled atmosphere for purity | Sintering, Heat-treating |

Protect your lab and your results with the right equipment. Proper ventilation is key to safe and effective muffle furnace operation. The experts at KINTEK specialize in lab equipment and consumables, helping you select and maintain the ideal furnace setup for your specific application—whether it's ashing, sintering, or high-purity research.

Contact us today via our secure form to discuss your laboratory needs and ensure your processes are both safe and efficient.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How does a high-precision muffle furnace facilitate the evaluation of ceramic performance? Master 1000-Hour Heat Testing

- What role does a high-temperature muffle furnace play in the preparation of TiO2 nanoparticles? Key Thermal Insights

- Why is a high-precision high-temperature furnace required for photosensitive glass? Master Controlled Crystallization

- What is the use of burnout furnace? Create Flawless Castings with Precision Mold Preparation

- What is the working principle of a muffle furnace? Achieve Precise, Contamination-Free Heating

- What is commonly used during a dry ashing experiment? Essential Equipment for Accurate Ash Analysis

- What is the primary function of high-temperature furnaces during physical activation? Master Carbon Pore Engineering

- What are the precautions of muffle furnace in laboratory? Ensure Operator Safety and Equipment Longevity