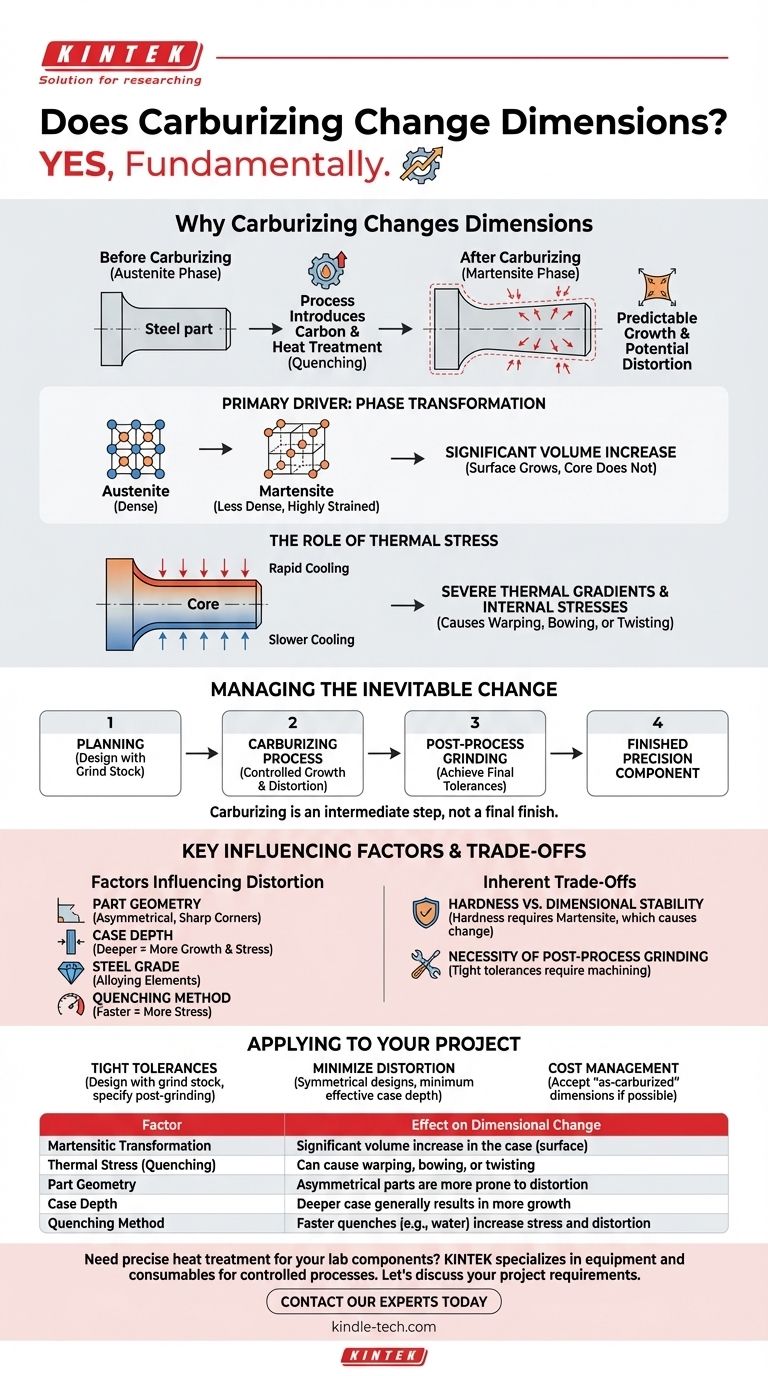

Yes, carburizing fundamentally changes the dimensions of a steel part. The process introduces carbon into the surface and involves a subsequent heat treatment (quenching) that alters the steel's microstructure, leading to predictable growth and potential distortion. This dimensional change is not an accident but an inherent consequence of the metallurgical transformations that produce the hard, wear-resistant surface.

The core issue is not if dimensions will change, but how to manage the change. Carburizing causes volume expansion and stress that necessitates planning for post-process machining, such as grinding, to achieve final tolerances.

Why Carburizing Changes Dimensions

The dimensional and shape changes during carburizing are not caused by a single factor, but by a combination of chemical and thermal effects. Understanding these drivers is key to predicting and controlling the outcome.

The Primary Driver: Phase Transformation

The most significant cause of dimensional change is the martensitic transformation. During quenching, the high-carbon steel surface (the case) rapidly cools and transforms from a dense structure called austenite to a less dense, highly strained structure called martensite.

This change from austenite to martensite causes a significant volume increase. Because this transformation only happens in the carbon-enriched case, the surface of the part literally grows while the softer, low-carbon core does not.

The Role of Thermal Stress

The rapid cooling inherent in quenching creates severe thermal gradients. The surface cools and contracts much faster than the core, inducing powerful internal stresses.

These stresses can cause the part to warp, bow, or twist. The final shape is a result of the battle between the volume expansion from martensite formation and the thermal contraction from cooling.

The Effect of Carbon Absorption

Simply diffusing carbon atoms into the iron crystal lattice causes a slight expansion. While this contributes to the overall growth, its effect is minor compared to the volume increase from the subsequent phase transformation during the quench.

Predicting and Managing the Change

While dimensional change is inevitable, its magnitude and nature can be controlled. The reference to needing "large material allowances for post-processing operations" highlights that managing this change is a standard part of the manufacturing process.

Key Factors Influencing Distortion

- Part Geometry: Asymmetrical parts, or those with sharp corners and thin sections, are far more prone to warping than simple, symmetrical shapes.

- Case Depth: A deeper carburized case generally results in more growth and higher internal stress.

- Steel Grade: The specific alloying elements in the steel affect how it responds to both carburizing and quenching.

- Quenching Method: The speed and uniformity of the quench have a direct impact on the level of thermal stress and distortion. Oil quenching is less severe than water quenching, for example.

The Inherent Trade-Offs

Choosing carburizing requires accepting and planning for its consequences. It is not a final-step process for high-precision components.

The Necessity of Post-Process Grinding

Because of the predictable growth and potential for distortion, parts that require tight tolerances must be machined after carburizing. A specific amount of "grind stock" is intentionally left on the part before heat treatment to be removed afterward.

Process Control vs. Final Form

As noted in the references, achieving repeatable results requires "empirically gained experience." A skilled heat treater can control the process to produce a consistent amount of growth and distortion, but they cannot eliminate it. This consistency is what makes post-process machining predictable and efficient.

Hardness vs. Dimensional Stability

The goal of carburizing is to create an extremely hard surface. This hardness is achieved by creating martensite, the very transformation that causes the most significant dimensional change. You cannot have one without the other.

How to Apply This to Your Project

Your strategy must incorporate dimensional change from the very beginning of the design process.

- If your primary focus is achieving tight final tolerances: Design the part with extra material (grind stock) on all critical surfaces and specify a post-carburizing grinding operation.

- If your primary focus is minimizing distortion: Design symmetrical parts where possible, avoid sharp internal corners, and specify the minimum effective case depth for your application.

- If your primary focus is managing cost for a non-critical part: Consider if the "as-carburized" dimensions are acceptable for the part's function, which eliminates the expense of post-process grinding.

Ultimately, you must treat carburizing as an intermediate manufacturing step, not a final finish.

Summary Table:

| Factor | Effect on Dimensional Change |

|---|---|

| Martensitic Transformation | Significant volume increase in the case (surface) |

| Thermal Stress (Quenching) | Can cause warping, bowing, or twisting |

| Part Geometry | Asymmetrical parts are more prone to distortion |

| Case Depth | Deeper case generally results in more growth |

| Quenching Method | Faster quenches (e.g., water) increase stress and distortion |

Need precise heat treatment for your lab components?

Carburizing is a powerful process for creating wear-resistant surfaces, but managing the resulting dimensional changes is critical for success. At KINTEK, we specialize in providing the lab equipment and consumables necessary for controlled heat treatment processes. Our expertise helps you plan for post-process grinding and achieve the tight tolerances your applications demand.

Let's discuss your project requirements. Contact our experts today to ensure your heat-treated parts meet your exact specifications.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the three types of furnaces? Choose the Right Furnace for Your Needs

- Why do we use a muffle furnace? For Pure, Precise, and Contaminant-Free High-Temperature Processing

- Why the melting temperature of ceramic is higher than for most metals? Unpacking Atomic Bond Strength

- Does casting change material properties? Understand the Microstructural Impact on Performance

- What are the environmental impacts of metal processing? A Guide to Sustainability and Solutions