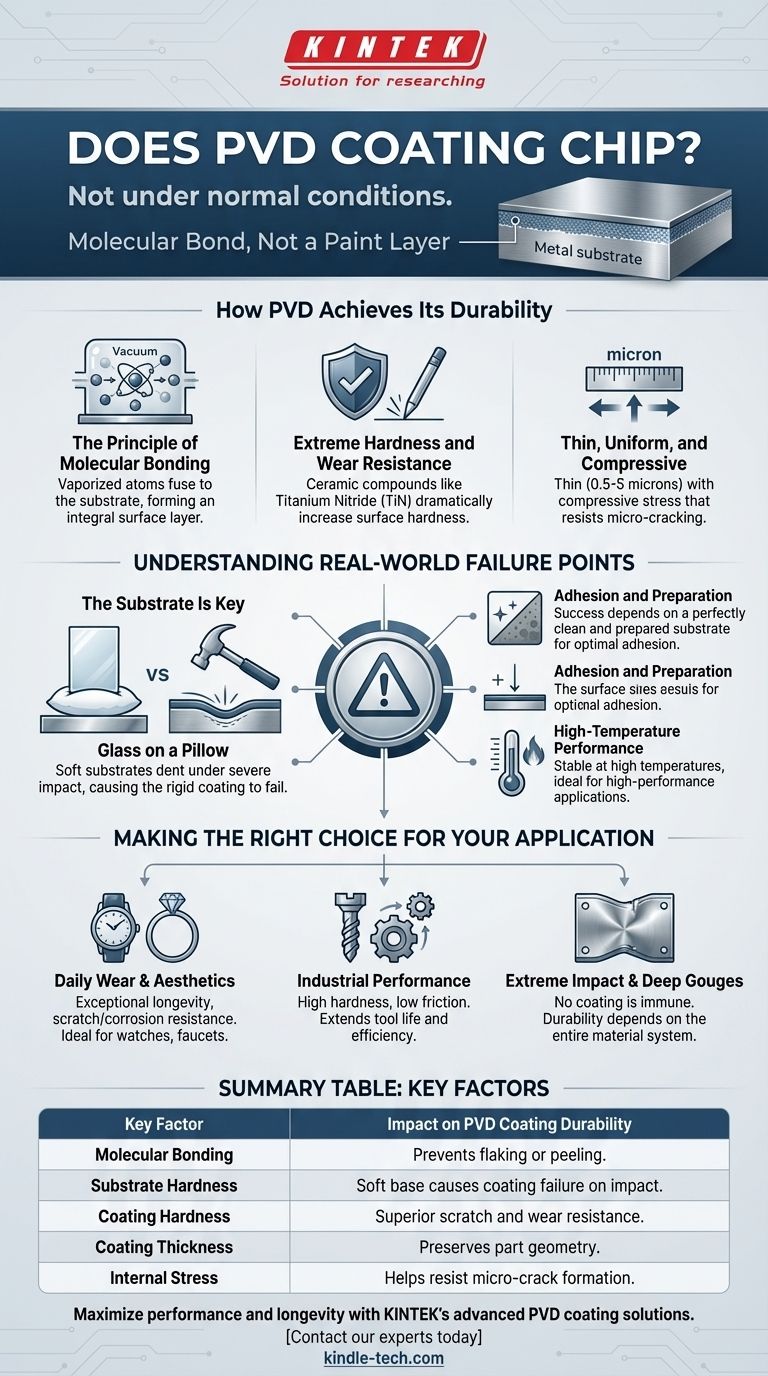

Under normal conditions, a properly applied PVD coating is exceptionally resistant to chipping. Unlike paint or traditional plating, Physical Vapor Deposition (PVD) is a process that bonds a thin film of metal or ceramic to a substrate at the molecular level. This creates a surface finish that is part of the object itself, rather than just a layer sitting on top, making it incredibly durable and unlikely to flake or chip from everyday use.

The core issue is not whether the PVD coating itself will chip, but whether the underlying material can support it. While the coating is extremely hard, a severe impact can dent or deform the softer substrate beneath it, causing the entire surface layer to fail in that specific location.

How PVD Achieves Its Durability

The Principle of Molecular Bonding

PVD is performed in a high-vacuum chamber where a solid material is vaporized into a plasma of atoms or molecules. These vaporized particles are then deposited onto the substrate, forming a new, bonded surface layer that is atomically fused with the base material.

Think of it less like a layer of paint and more like the surface of the metal itself has been fundamentally changed. This molecular bond is the primary reason PVD coatings demonstrate such high adhesion and resistance to peeling or flaking.

Extreme Hardness and Wear Resistance

PVD can deposit ceramic compounds like Titanium Nitride (TiN), which dramatically increase the surface hardness of the final product. This enhanced hardness provides superior resistance to scratches, abrasion, and daily wear.

The hardness of the coating is a critical factor in its overall durability. For example, applying a TiN coating to a titanium alloy can increase its fatigue limit and endurance, making it more resilient to repeated stress.

Thin, Uniform, and Compressive

PVD coatings are remarkably thin, typically ranging from 0.5 to 5 microns. This thinness ensures the original texture and sharp edges of the substrate are preserved, which is critical for applications like cutting tools.

Crucially, the PVD process often creates compressive stress within the coating layer as it cools. This internal stress works to hold the coating together, actively resisting the formation and propagation of micro-cracks that could lead to chipping.

Understanding the Real-World Failure Points

The Substrate Is the Key

The single most important factor in PVD chipping is the hardness of the underlying material, or substrate. A very hard PVD coating on a very soft base metal creates a scenario like glass on a pillow.

If the base metal is dented or gouged by a significant impact, the rigid PVD coating bonded to it has no choice but to deform or break along with it. The failure is not the coating "chipping off," but the entire surface system failing due to the substrate's deformation.

The Role of Adhesion and Preparation

While the PVD process creates an excellent bond, its success is dependent on a perfectly clean and prepared substrate. Improper pre-treatment can lead to poor adhesion, which could cause the coating to fail prematurely.

However, when performed correctly, the adhesion of PVD is far superior to that of traditional electroplating or painting.

High-Temperature Performance

PVD coatings are applied at high temperatures (typically 250°C to 750°C) and are engineered to be highly resistant to heat and corrosion. This makes them exceptionally stable and suitable for high-performance applications, such as protecting industrial cutting tools from the heat and friction of milling.

Making the Right Choice for Your Application

Choosing a finish requires understanding its limits. PVD is a top-tier performer in surface durability, but it is not indestructible.

- If your primary focus is daily wear and aesthetics (watches, faucets, jewelry): PVD offers exceptional longevity and will resist scratches, corrosion, and discoloration far better than almost any alternative.

- If your primary focus is industrial performance (cutting tools, components): The combination of high hardness, low friction, and resistance to cracking makes PVD an ideal choice for extending tool life and improving efficiency.

- If your primary focus is resistance to extreme impact and deep gouges: Remember that no coating can make a soft material immune to denting; the durability of the final product is a function of the entire material system.

By understanding that PVD’s strength lies in its molecular bond to the substrate, you can confidently specify it for applications where surface integrity and longevity are paramount.

Summary Table:

| Key Factor | Impact on PVD Coating Durability |

|---|---|

| Molecular Bonding | Creates an atomically fused layer, preventing flaking or peeling. |

| Substrate Hardness | A soft base metal can dent, causing the rigid coating to fail. |

| Coating Hardness | Ceramic coatings like TiN provide superior scratch and wear resistance. |

| Coating Thickness | Thin (0.5-5 microns) and uniform, preserving part geometry. |

| Internal Stress | Compressive stress helps resist micro-crack formation. |

Maximize the performance and longevity of your components with KINTEK's advanced PVD coating solutions.

As specialists in lab equipment and consumables, we understand that surface integrity is critical for your tools and parts. Our PVD coatings provide unparalleled hardness, wear resistance, and durability, extending the life of your most demanding equipment.

Ready to enhance your product's durability? Contact our experts today to discuss how our PVD coatings can solve your specific wear and corrosion challenges.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability