In short, no. PVD (Physical Vapor Deposition) coatings are not easily scratched. They are specifically engineered to create a very hard, durable surface that is significantly more resistant to abrasion and wear than traditional plating methods or the base material itself. The process creates a thin film that is atomically bonded to the metal, resulting in a finish that is exceptionally tough for its thickness.

The scratch resistance of a PVD coating is extremely high, but its real-world performance is a function of two things: the hardness of the coating itself and the hardness of the material underneath it. A hard coating on a soft metal can still be damaged by an impact that deforms the underlying substrate.

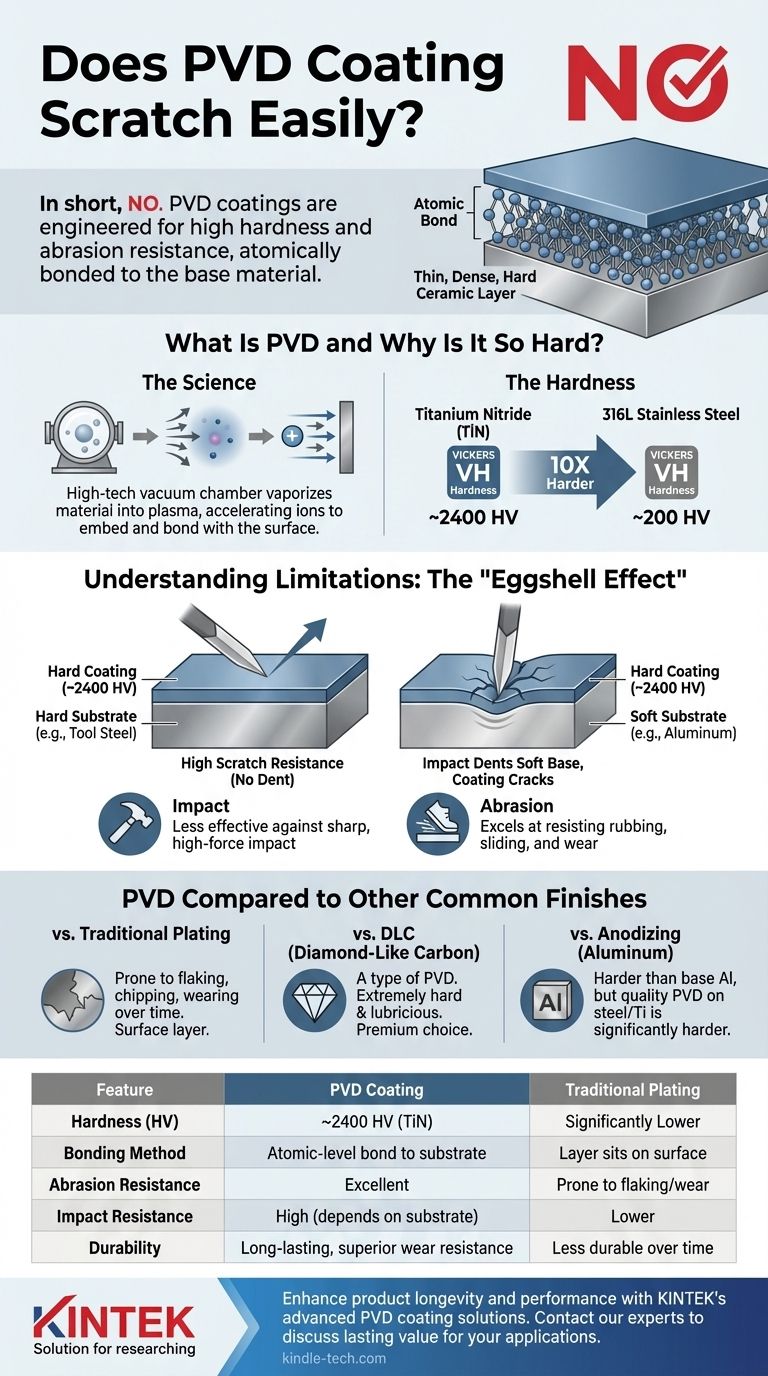

What Is PVD and Why Is It So Hard?

To understand PVD's durability, you must first understand the process. It is not a paint, powder coat, or simple plating method.

The Science in Simple Terms

Imagine the difference between painting a wall and staining wood. Paint sits on the surface, while stain soaks in and becomes part of the wood fibers.

PVD is more like the staining analogy, but on a molecular level. In a high-tech vacuum chamber, a solid material (like titanium nitride) is vaporized into a plasma of atoms and ions. An electrical voltage then accelerates these particles toward the object being coated, causing them to embed into and bond with its surface.

How This Process Creates Hardness

This process forms a thin, dense, and exceptionally well-bonded ceramic layer. This layer, often just a few microns thick, is what provides the hardness.

For example, a common PVD coating like Titanium Nitride (TiN) has a Vickers hardness of around 2400 HV, whereas 316L stainless steel is only about 200 HV. The PVD coating is literally an order of magnitude harder than the steel it protects.

Understanding the Trade-offs and Limitations

While extremely durable, PVD coatings are not indestructible. Their limitations are predictable and important to understand for any application.

The "Eggshell Effect"

This is the single most important concept for understanding PVD durability. A PVD coating is like a hard eggshell. If you place that eggshell on a hard surface like a granite countertop, it's very difficult to scratch.

However, if you place that same eggshell on a soft sponge and press down, the sponge will deform and the hard shell will crack.

The same is true for PVD. A hard PVD coating on a soft base metal (like aluminum or softer stainless steel) is highly resistant to surface scratches. But a sharp impact can dent the soft metal underneath, causing the PVD coating to deform and potentially crack or chip along with the dent. The damage you see is not from the coating scratching, but from the failure of the entire material system.

Impact vs. Abrasion

PVD coatings excel at resisting abrasion. This includes rubbing, sliding, or general wear from contact with other surfaces. This is why it's used on cutting tools, watch bracelets, and door hardware.

It is less effective against a sharp, high-force impact. A direct hit with a sharp object can exceed the substrate's strength, leading to the "eggshell effect" described above.

PVD Compared to Other Common Finishes

Context is key. PVD's value becomes clear when compared to other common finishing methods.

vs. Traditional Plating (e.g., Electroplating)

PVD is far superior in terms of hardness and adhesion. Traditional plating is prone to flaking, chipping, and wearing away over time because it is a distinct layer sitting on top of the metal. PVD's atomic bond prevents this.

vs. DLC (Diamond-Like Carbon)

DLC is actually a specific type of PVD coating. It is among the hardest and most lubricious PVD options available, offering even greater scratch resistance than standard coatings like Titanium Nitride. It is often considered a premium choice for high-end watches and performance tools.

vs. Anodizing (on Aluminum)

Anodizing is a process that converts the surface of aluminum into aluminum oxide, which is harder than the base aluminum. However, a high-quality PVD coating applied over steel or titanium is significantly harder and more scratch-resistant than a standard anodized aluminum finish.

Making the Right Choice for Your Application

Ultimately, the choice depends on your specific goal and the environment the product will face.

- If your primary focus is maximum durability for tools or high-end watches: Choose a PVD or DLC coating on a very hard substrate material like hardened tool steel or titanium.

- If your primary focus is color and daily wear resistance for jewelry or hardware: PVD is an excellent choice, but be aware that on softer base metals, severe impacts can still cause dents.

- If your primary focus is decorative color on a budget: Traditional plating or powder coating may suffice, but you will be sacrificing the superior longevity and wear resistance of PVD.

By understanding that PVD's strength lies in its synergy with the base material, you can accurately judge its value and longevity for any product.

Summary Table:

| Feature | PVD Coating | Traditional Plating |

|---|---|---|

| Hardness (Vickers HV) | ~2400 HV (Titanium Nitride) | Significantly Lower |

| Bonding Method | Atomic-level bond to substrate | Layer sits on surface |

| Abrasion Resistance | Excellent | Prone to flaking/wear |

| Impact Resistance | High (depends on substrate hardness) | Lower |

| Durability | Long-lasting, superior wear resistance | Less durable over time |

Enhance your product's longevity and performance with KINTEK's advanced PVD coating solutions.

As a specialist in laboratory equipment and consumables, KINTEK understands the critical need for durable, high-quality finishes that can withstand demanding environments. Our PVD coating services provide a hard, wear-resistant surface that is atomically bonded to your components, ensuring superior protection against abrasion and daily wear.

Whether you are manufacturing precision tools, high-end watches, or durable hardware, our expertise can help you select the ideal coating and substrate combination to maximize durability and performance. We work with you to achieve a finish that not only looks exceptional but also stands the test of time.

Ready to elevate your product's durability? Contact our experts today to discuss how KINTEK's PVD coating solutions can bring lasting value to your applications.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

People Also Ask

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- Is diamond coating worth it? Maximize Component Life and Performance

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance