In short: no, PVD plating itself does not tarnish. The process creates a hard, inert barrier on the surface of a material that is exceptionally resistant to the chemical reaction that causes tarnish. Its fundamental properties of high corrosion and abrasion resistance prevent the degradation that plagues many other metals and finishes.

The core reason PVD (Physical Vapor Deposition) coatings don't tarnish is that they create a chemically non-reactive surface. While the coating itself is extremely stable, its long-term effectiveness is ultimately defined by its ability to withstand physical wear and tear that could expose the base material underneath.

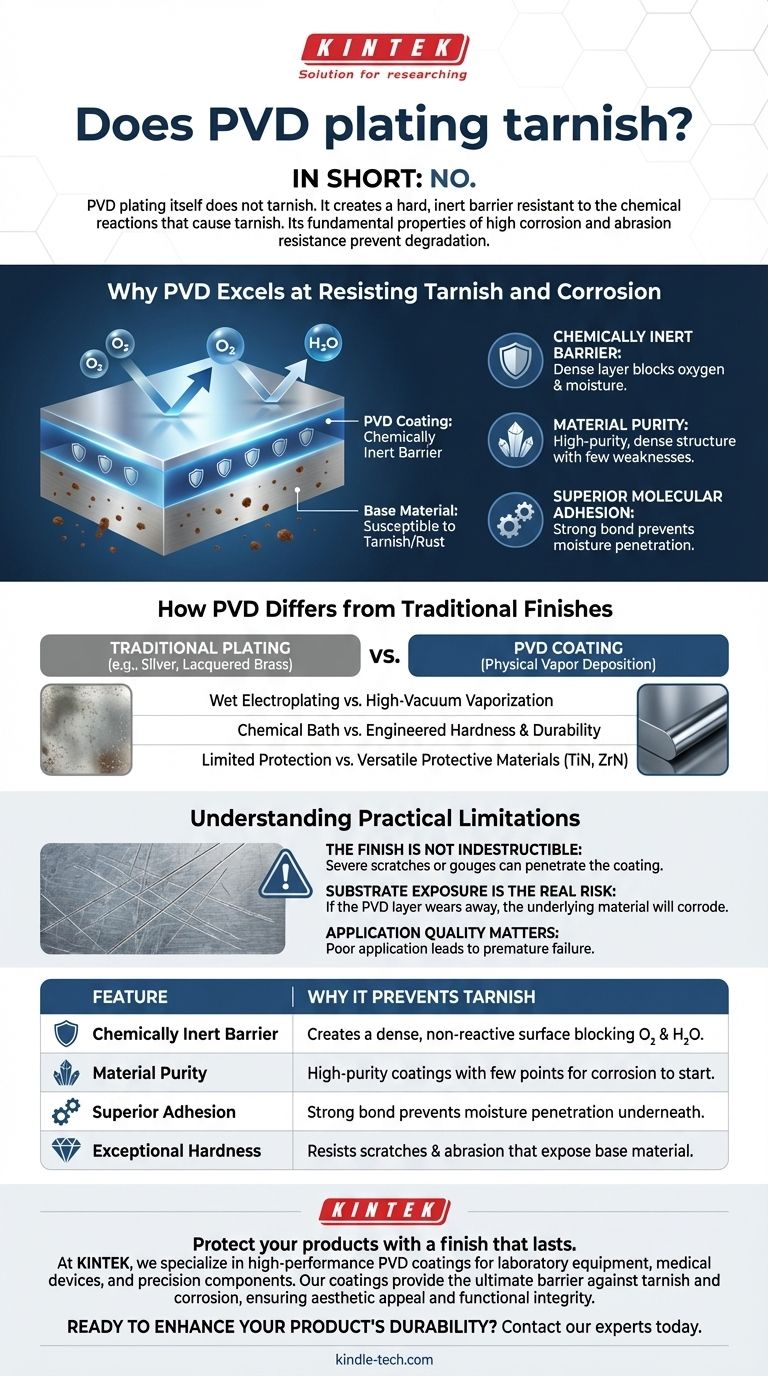

Why PVD Excels at Resisting Tarnish and Corrosion

Tarnish is simply a mild form of corrosion, a chemical reaction that occurs when a metal's surface is exposed to air and moisture. PVD coatings are specifically engineered to prevent this process at a molecular level.

A Chemically Inert Barrier

PVD deposits an extremely thin but dense layer of material onto a substrate. This coating is chosen for its chemical stability and acts as a shield, preventing oxygen and other environmental elements from reaching the base metal.

The Role of Material Purity

The PVD process creates extremely pure, high-performance coatings. This purity and dense structure leave very few points of weakness where a corrosive reaction like tarnishing could begin.

Superior Molecular Adhesion

Unlike some traditional plating methods, PVD forms a powerful bond with the underlying material. This strong adherence ensures there are no gaps or pores where moisture could penetrate and cause the substrate to corrode from beneath the coating.

How PVD Differs from Traditional Finishes

Understanding the PVD process reveals why it offers superior protection compared to finishes that are prone to tarnishing, such as traditional silver plating or lacquered brass.

Beyond a Simple Chemical Bath

PVD is not a wet electroplating process. It takes place in a high-vacuum chamber where a solid material is vaporized into plasma and then bonded to the object, creating an extremely hard and durable finish.

Engineered for Hardness and Durability

The primary benefits cited for PVD are its hardness and resistance to scratches and abrasion. A finish that can withstand physical damage is far more likely to maintain its protective barrier over time.

Versatility in Protective Materials

The process allows for the use of various inorganic materials, such as Titanium Nitride and Zirconium Nitride. These materials are chosen specifically for their robust protective properties, including their inherent resistance to corrosion and chemical attack.

Understanding the Practical Limitations

While the PVD coating itself is stable, it's critical to understand that it is a surface layer. Its purpose is to protect the material underneath, and its limitations are primarily physical, not chemical.

The Finish Is Not Indestructible

PVD coatings are exceptionally durable but not invincible. A severe scratch or deep gouge from a sharp object can penetrate the coating.

Substrate Exposure Is the Real Risk

The primary point of failure is when the PVD layer is worn away or scratched through, exposing the base metal. If the underlying material (like brass, copper, or steel) is susceptible to tarnish or rust, it will begin to corrode once exposed.

The Impact of Application Quality

The performance of a PVD coating is heavily influenced by the quality of the application process. A poorly applied coating may not adhere properly, leading to premature failure and a loss of its protective qualities.

Making the Right Choice for Your Application

Choosing PVD is an investment in long-term surface stability. To determine if it’s the right solution, consider the primary stress your product will endure.

- If your primary focus is aesthetic longevity for items like jewelry, watches, or fixtures: PVD is an outstanding choice that provides a tarnish-free finish that will not require polishing.

- If your primary focus is durability against high wear and abrasion: The specific PVD material and its applied thickness are the most critical factors to ensure the protective layer isn't physically worn away.

- If your primary focus is environmental resistance in a corrosive setting: PVD's inert nature makes it a superior option to most traditional platings for preventing chemical degradation.

Ultimately, choosing PVD means prioritizing a finish that maintains its integrity through exceptional chemical stability and physical resilience.

Summary Table:

| Feature | Why It Prevents Tarnish |

|---|---|

| Chemically Inert Barrier | Creates a dense, non-reactive surface that blocks oxygen and moisture. |

| Material Purity | High-purity coatings with few weaknesses for corrosion to start. |

| Superior Adhesion | Strong bond prevents moisture penetration underneath the coating. |

| Exceptional Hardness | Resists scratches and abrasion that could expose the base material. |

Protect your products with a finish that lasts.

At KINTEK, we specialize in high-performance PVD coatings for laboratory equipment, medical devices, and precision components. Our coatings provide the ultimate barrier against tarnish and corrosion, ensuring your products maintain their aesthetic appeal and functional integrity in demanding environments.

Ready to enhance your product's durability? Contact our experts today to discuss how our PVD solutions can meet your specific needs.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance