While no surface coating is indestructible, PVD coatings are exceptionally resistant to wear. Unlike traditional plating that can chip or flake, a properly applied PVD finish is so durable that it typically outlasts the lifetime of the product itself under normal use. Significant wear only occurs under extreme abrasion over a long period.

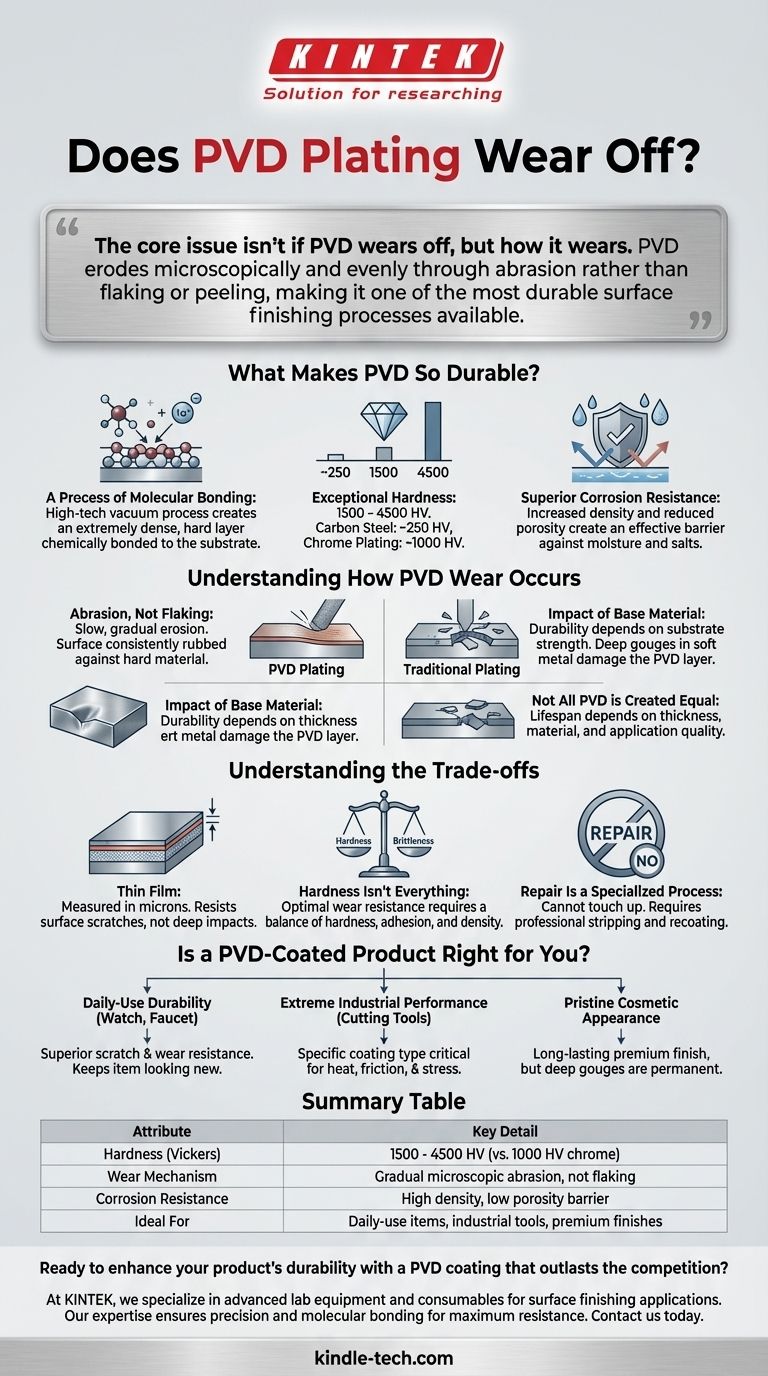

The core issue isn't if PVD wears off, but how it wears. PVD erodes microscopically and evenly through abrasion rather than flaking or peeling, making it one of the most durable surface finishing processes available.

What Makes PVD So Durable?

Physical Vapor Deposition (PVD) is not a simple coating like paint; it is a high-tech vacuum process that molecularly bonds the finishing material to the product's surface. This fundamental difference is the source of its superior performance.

A Process of Molecular Bonding

The PVD process places the item in a vacuum chamber and bombards its surface with ions of the coating material. This creates an extremely dense, hard, and resilient layer that is chemically bonded to the substrate. It becomes part of the surface, not just a layer sitting on top of it.

Exceptional Hardness

PVD coatings are incredibly hard. They typically measure between 1500 and 4500 on the Vickers hardness scale (HV).

To put that in perspective, standard carbon steels are around 250 HV, and durable chrome plating is around 1000 HV. This extreme hardness is a primary reason PVD is so resistant to scratches and everyday wear.

Superior Corrosion Resistance

The ion bombardment during the PVD process increases the coating's density and reduces its porosity. This creates a highly effective barrier against moisture, salts, and other corrosive agents, preventing rust or tarnish on the underlying material that could compromise the finish.

Understanding How PVD Wear Occurs

Because PVD doesn't chip or flake, its failure mode is different from what many people expect from a "plated" finish.

Abrasion, Not Flaking

Wear on a PVD coating is a process of slow, gradual erosion. It happens when the surface is consistently rubbed against an equally hard or harder material. For a watch or faucet, this might mean years of contact with abrasive dust, sand, or other harsh elements. The finish will thin over time rather than peel away.

The Impact of the Base Material

The durability of the coating also depends on the strength of the material underneath it. While the PVD layer is extremely hard, it is also very thin. A deep gouge or dent in a soft base metal will damage the PVD layer along with it.

Not All PVD is Created Equal

The lifespan of a PVD coating depends on its thickness, the specific material used (e.g., Titanium Nitride vs. DLC), and the quality of the application process. A coating designed for a decorative item will be different from one designed for an industrial cutting tool.

Understanding the Trade-offs

While PVD is a superior technology, it's important to recognize its practical limitations.

It Is a Thin Film

PVD coatings are measured in microns. They are designed to resist surface-level scratches and abrasion, not deep impacts or gouges from sharp metal tools. A deep enough scratch will always penetrate the coating and expose the substrate.

Hardness Isn't Everything

There is an optimal hardness level for wear resistance. A coating that is too hard can become brittle. True durability comes from a balance of hardness, adhesion, and density, which is achieved through a precisely controlled application process.

Repair Is a Specialized Process

You cannot simply "touch up" a damaged PVD finish. Repairing a significant scratch or worn area typically requires the entire object to be professionally stripped and recoated, which can be costly and is not always feasible.

Is a PVD-Coated Product Right for You?

Choosing a PVD-coated item is an investment in long-term durability. Use these points to guide your decision based on your primary goal.

- If your primary focus is daily-use durability (e.g., watch, jewelry, faucet): PVD offers superior scratch and wear resistance that will keep the item looking new far longer than traditional plating methods.

- If your primary focus is extreme industrial performance (e.g., cutting tools): The specific type and quality of the PVD coating are critical, as it must be engineered to withstand immense heat, friction, and stress.

- If your primary focus is maintaining pristine cosmetic appearance: PVD provides a long-lasting premium finish, but understand that deep gouges are permanent and cannot be easily buffed out or repaired.

Ultimately, choosing a PVD-coated product is a choice for exceptional resilience against the wear and tear of daily life.

Summary Table:

| PVD Coating Attribute | Key Detail |

|---|---|

| Hardness (Vickers) | 1500 - 4500 HV (vs. 1000 HV for chrome plating) |

| Wear Mechanism | Gradual microscopic abrasion, not flaking or peeling |

| Corrosion Resistance | High density and low porosity create an effective barrier |

| Ideal For | Daily-use items (watches, jewelry), industrial tools, and premium finishes |

Ready to enhance your product's durability with a PVD coating that outlasts the competition?

At KINTEK, we specialize in advanced lab equipment and consumables for surface finishing applications. Our expertise ensures your PVD coatings are applied with precision, offering molecular bonding for maximum wear and corrosion resistance. Whether you're in manufacturing, jewelry, or tooling, KINTEK provides the solutions you need for superior, long-lasting results.

Contact us today to discuss how our PVD solutions can meet your specific laboratory and production needs!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Isostatic Molding Pressing Molds for Lab

People Also Ask

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- Is diamond coating worth it? Maximize Component Life and Performance

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance