In principle, no. The core purpose of pyrolysis is to be a clean-energy conversion process, but its environmental impact depends entirely on how it's executed. When properly managed with sustainable materials, it is a powerful tool for reducing pollution; however, poor controls or unsustainable sourcing can create significant environmental problems.

The environmental footprint of pyrolysis is not determined by the technology itself, but by the quality of its management. The key factors are the sustainability of the input material (the feedstock) and the precision of the process control.

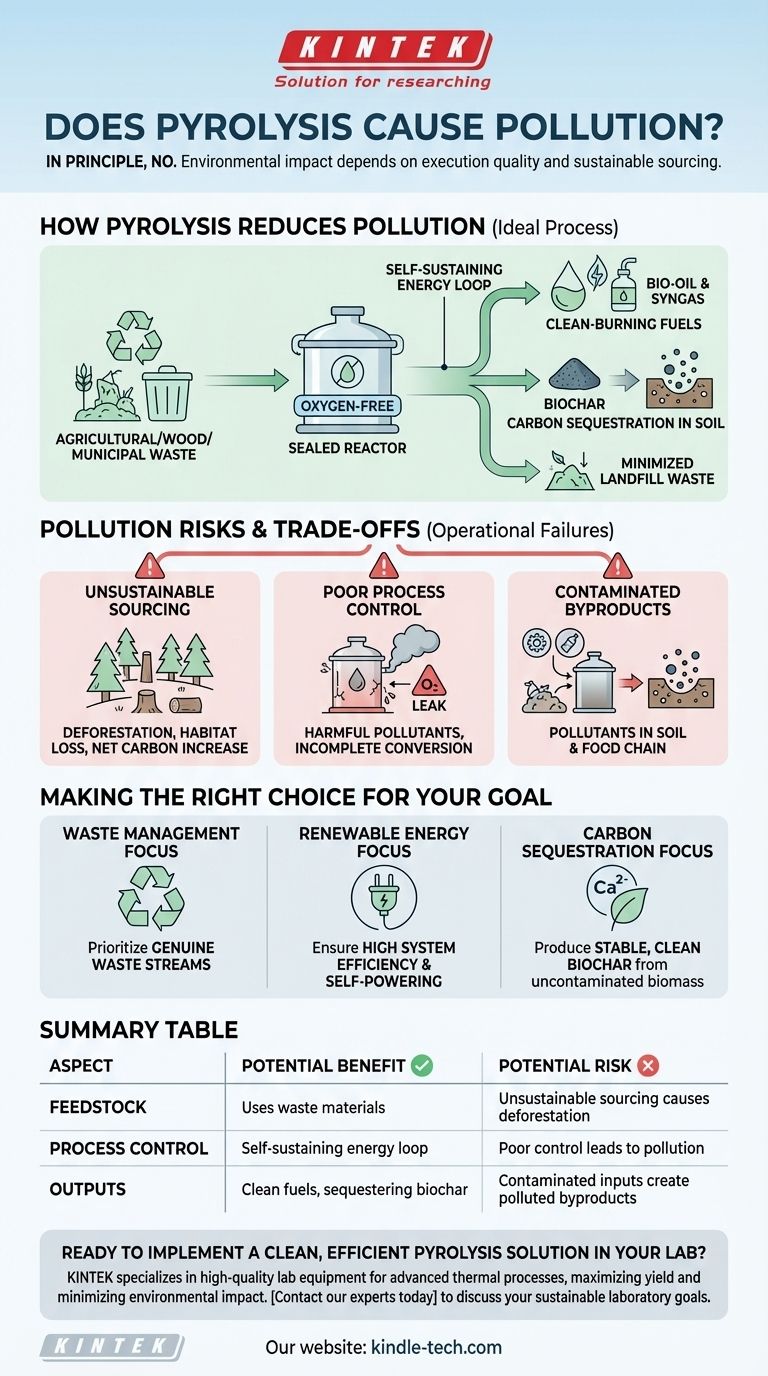

How Pyrolysis Is Designed to Reduce Pollution

Pyrolysis is the thermal decomposition of materials at high temperatures in an inert atmosphere, meaning in the absence of oxygen. This is fundamentally different from incineration (burning), and this distinction is the primary reason for its environmental benefits.

Converting Waste into Valuable Resources

Pyrolysis transforms materials that might otherwise end up in a landfill—such as agricultural residues, wood waste, or municipal solid waste—into valuable products.

This process creates bio-oil and syngas, which can be used as clean-burning fuels, reducing our dependence on fossil fuels and the pollution associated with their extraction and combustion.

Sequestering Carbon with Biochar

The solid byproduct of pyrolysis is a stable, carbon-rich material called biochar.

When added to soil, biochar doesn't decompose for hundreds or thousands of years. This effectively locks carbon away, preventing it from entering the atmosphere as CO2, a process known as carbon sequestration.

Creating a Self-Sustaining Energy Loop

Modern pyrolysis systems are highly efficient and can often be energy self-sufficient.

The syngas produced during the process can be circled back to provide the heat needed to run the system, creating a closed-loop process that doesn't require an external energy source once it's operational.

Understanding the Trade-offs and Pollution Risks

While the technology is sound, its real-world application introduces risks that must be managed carefully. Pollution from pyrolysis is not a result of the core process, but of operational failures and poor planning.

The Problem of Feedstock Sourcing

The single largest environmental risk is the source of the biomass.

If pyrolysis relies on virgin forests or crops that displace food agriculture, it can lead to deforestation, habitat destruction, and a net increase in carbon emissions. True environmental benefit is only achieved when using genuine waste materials.

The Impact of Poor Process Control

A poorly sealed or improperly managed pyrolysis reactor can fail to maintain an oxygen-free environment.

This can lead to unintentional combustion, releasing harmful pollutants. Likewise, if temperatures are not correctly controlled, the conversion can be incomplete, resulting in a less-than-optimal yield of products and potentially hazardous byproducts.

Contamination in Byproducts

If the initial feedstock (like municipal solid waste) contains contaminants such as heavy metals or plastics, these elements can become concentrated in the resulting bio-oil or biochar.

Using this contaminated biochar in agriculture could introduce pollutants into the soil and food chain. This requires careful pre-sorting of waste and rigorous testing of the final products.

Making the Right Choice for Your Goal

To determine if pyrolysis is the right solution, you must first clarify your primary objective.

- If your primary focus is sustainable waste management: Prioritize using genuine waste streams, such as agricultural residue or sorted municipal waste, to ensure you are solving a problem, not creating a new one.

- If your primary focus is renewable energy production: Verify that the system is highly efficient and capable of using its own syngas for power, minimizing external energy inputs.

- If your primary focus is carbon sequestration: Concentrate on producing stable, high-quality biochar from clean, uncontaminated biomass and ensure it has a clear path for use in agriculture or land remediation.

Ultimately, pyrolysis is a tool whose environmental benefit is realized only through responsible and intelligent application.

Summary Table:

| Aspect | Potential Benefit | Potential Risk |

|---|---|---|

| Feedstock | Uses waste materials (e.g., agricultural residue) | Unsustainable sourcing causes deforestation |

| Process Control | Creates a self-sustaining energy loop | Poor control leads to incomplete conversion & pollution |

| Outputs | Produces clean bio-oil, syngas, and sequestering biochar | Contaminated inputs create polluted byproducts |

Ready to implement a clean, efficient pyrolysis solution in your lab?

KINTEK specializes in high-quality lab equipment and consumables for advanced thermal processes. Whether you're researching waste conversion, biochar production, or renewable energy, our precise and reliable pyrolysis systems help you achieve optimal, controlled results—maximizing yield and minimizing environmental impact.

Contact our experts today to discuss how we can support your sustainable laboratory goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What temperature is a carbon regeneration kiln? Master the 650°C-800°C Range for Optimal Results

- What is the temperature of a rotary hearth furnace? Find the Right Heat for Your Process

- What temperature is needed for porcelain? A Guide to Cone 6 and Cone 10 Firing

- What is the temperature of a carbon regeneration kiln? Mastering the 750-800°C Reactivation Process

- What is the temperature for activated carbon regeneration? Key Ranges from 220°C to 900°C