Yes, atomic diffusion is the fundamental mechanism that makes sintering possible. When a collection of powder particles is heated, the atoms gain enough thermal energy to move and rearrange themselves. This atomic movement, or diffusion, allows the individual particles to bond together, reducing the empty space (porosity) between them and forming a solid, coherent mass long before the material reaches its melting point.

Sintering is not a process of melting particles together. Instead, it leverages thermally-activated atomic diffusion to eliminate the surfaces between particles, effectively welding them together on an atomic scale to create a dense, solid object.

How Heat and Diffusion Drive the Sintering Process

To understand sintering, it's crucial to look beyond the high-level process and focus on the behavior of individual atoms. The entire goal is to reduce the system's total energy.

The Role of Thermal Energy

Heating a powder compact provides the necessary activation energy for its atoms. This energy doesn't melt the bulk material but causes the atoms within the crystal lattice to vibrate intensely.

This vibration gives atoms the ability to break their fixed bonds and migrate, or diffuse, from one location to another.

Atomic Diffusion in Action

Diffusion is the net movement of atoms from an area of high concentration to an area of low concentration. In sintering, the particles themselves are areas of high atomic concentration, and the pores or voids between them are areas of zero concentration.

Atoms migrate to fill these voids, bridging the gaps between adjacent particles. This process begins by forming small "necks" at the points of contact, which gradually grow until the pores are eliminated.

The Goal: Minimizing Surface Energy

A fine powder has an enormous amount of surface area relative to its volume. From a thermodynamic perspective, this is a high-energy, unstable state.

By bonding together and eliminating the internal surfaces of the pores, the material achieves a more stable, lower-energy state. Diffusion is simply the physical mechanism the material uses to reach this preferred state.

Key Sintering Mechanisms and the Role of Diffusion

While diffusion is always the core driver, how it occurs can vary. The two primary approaches are solid-state and liquid-phase sintering.

Solid-State Sintering

This is the purest form of the process, where the material remains entirely solid throughout.

Diffusion occurs through several pathways, including along the surface of the particles, along the boundaries between grains, and through the bulk of the crystal lattice itself. This method offers excellent dimensional control.

Liquid-Phase Sintering

In this technique, a small fraction of the material (or an added binder) melts at the sintering temperature, creating a liquid phase that coexists with the solid particles.

This liquid acts as a high-speed transport path. Atoms from the solid particles dissolve into the liquid, diffuse rapidly through it, and re-precipitate at the growing necks between particles. This significantly accelerates densification.

Understanding the Trade-offs

Controlling diffusion is a balancing act. The variables you manipulate to encourage diffusion have direct consequences on the final product.

Time and Temperature

This is the central trade-off. Higher temperatures increase the rate of diffusion exponentially, reducing the time needed to achieve density.

However, excessively high temperatures can cause unwanted grain growth, which can degrade the mechanical properties of the final material.

Porosity vs. Shrinkage

The direct result of eliminating porosity is that the overall component shrinks. Sintering is fundamentally a process of densification.

This shrinkage must be precisely predicted and accounted for in the initial design of the part, often requiring complex modeling and empirical testing.

The Liquid Phase Advantage and Risk

While liquid-phase sintering is faster and can lead to higher densities, it introduces complexity.

The amount and viscosity of the liquid must be carefully controlled. Too much liquid can cause the part to slump or lose its shape, while too little will not provide the intended acceleration.

Making the Right Choice for Your Goal

Understanding that diffusion is the engine of sintering allows you to select and control the process to achieve specific material properties.

- If your primary focus is high purity and precise dimensional control: Solid-state sintering is often the superior choice, as it avoids the complexities and potential contamination of a liquid phase.

- If your primary focus is speed and achieving maximum density: Liquid-phase sintering is highly effective because the liquid provides a fast path for the required atomic transport.

- If you are working with very strong materials (like ceramics or refractory metals): Advanced methods like hot pressing or laser sintering (DMLS) use external pressure or intense, localized energy to assist the natural diffusion process.

Ultimately, mastering sintering means mastering the control of atomic diffusion to build a stronger, denser material from the atom up.

Summary Table:

| Sintering Type | Primary Diffusion Mechanism | Key Advantage |

|---|---|---|

| Solid-State | Diffusion through solid lattice, grain boundaries, or surfaces | Excellent dimensional control and purity |

| Liquid-Phase | Rapid diffusion through a liquid phase | Faster densification and higher final density |

Ready to master the sintering process for your materials?

KINTEK specializes in providing the advanced lab equipment and consumables necessary to precisely control temperature, atmosphere, and time—the critical variables that govern diffusion and determine your final product's properties. Whether you are developing new ceramics, metals, or composites, our solutions help you achieve the perfect balance of density, strength, and dimensional accuracy.

Contact us today to discuss how we can support your laboratory's sintering R&D and production goals.

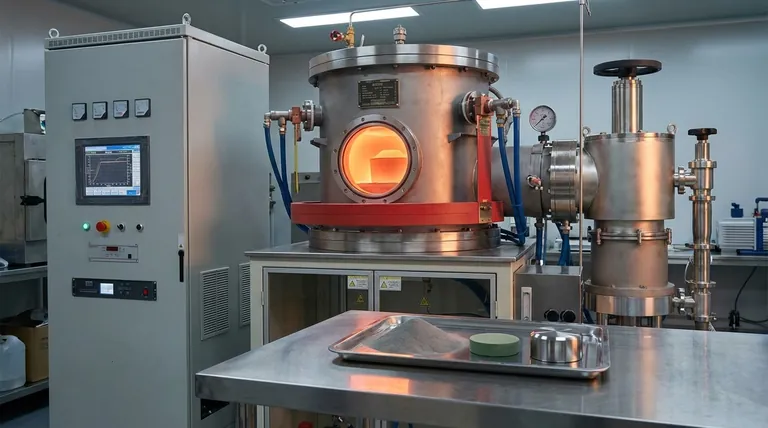

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the defects in sintered parts? Avoid Warping, Cracking, and Porosity Issues

- What is vacuum sintering? Achieve Unmatched Purity and Performance for Advanced Materials

- Why would you braze instead of solder? For Superior Joint Strength and High-Temperature Performance

- What are the methods of brazing heating? Choose the Right Method for Your Production Needs

- What is sintering reaction? Transform Powders into Dense Solids Without Melting