In modern medicine, ceramics are primarily used to create highly durable and biocompatible surgical implants. Materials like alumina are processed at extreme temperatures to form components for devices such as artificial hip and knee joints, where exceptional wear resistance is critical for long-term performance inside the human body.

The true value of ceramics in medicine is their unique combination of properties: they are not just hard, but are also chemically inert and biocompatible, meaning the body does not attack them as a foreign material. This allows them to function safely for decades in demanding applications.

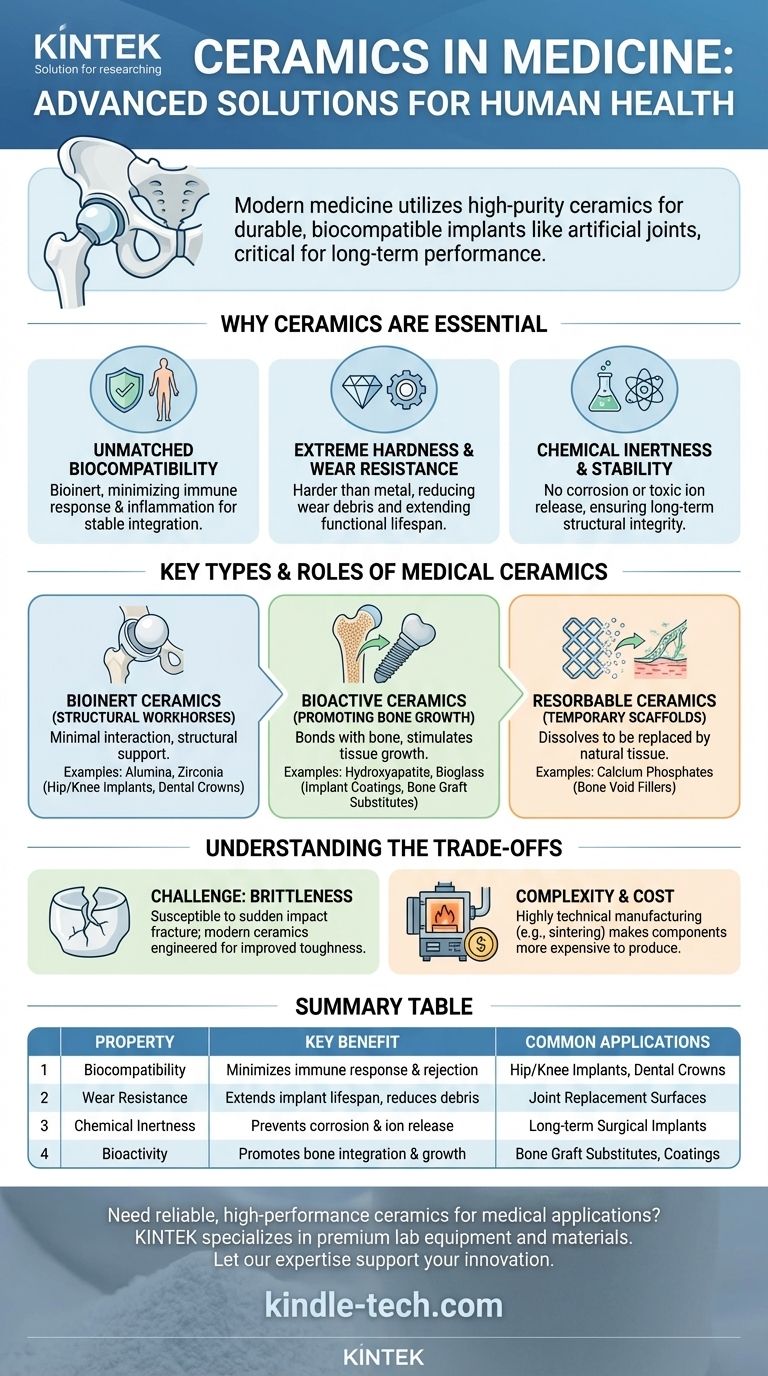

Why Ceramics are Essential in Medicine

The use of ceramics is not accidental; they are chosen for a specific set of properties that make them uniquely suited for integration with human biology. These characteristics solve critical problems that metals or polymers alone cannot.

Unmatched Biocompatibility

Biocompatibility is the ability of a material to exist within a biological system without causing a negative reaction. High-purity ceramics are bioinert, meaning the body’s immune system largely ignores them.

This prevents the inflammation, allergic reactions, and rejection issues that can occur with other materials, ensuring the implant remains stable and harmless over its lifetime.

Extreme Hardness and Wear Resistance

Ceramic components, particularly in joint replacements, are significantly harder and smoother than their metal counterparts. This is their most recognized advantage.

This extreme wear resistance means the implant degrades very slowly, generating far less debris. Less debris translates to a lower risk of inflammation in surrounding tissues and a longer functional lifespan for the implant.

Chemical Inertness and Stability

Unlike some metals, medical-grade ceramics do not corrode or release metallic ions into the bloodstream when exposed to the body's internal environment.

This chemical stability is crucial for long-term safety, preventing potential toxicity and ensuring the material's structural integrity is not compromised over time.

Key Types of Medical Ceramics and Their Roles

Medical ceramics are not a single category. They are separated into distinct classes based on how they interact with the body's tissues.

Bioinert Ceramics: The Structural Workhorses

These ceramics are designed to have minimal interaction with the body. Their job is to provide structural support without triggering a biological response.

Alumina and Zirconia are the leading examples. They are used for the load-bearing surfaces in hip and knee replacements and for durable dental crowns and bridges.

Bioactive Ceramics: Promoting Bone Growth

This class of ceramics is designed to bond directly with bone and stimulate new tissue growth. They are not inert; they are designed to be "active."

Materials like Hydroxyapatite (HA) and Bioglass are often used as coatings on metal implants (like titanium hip stems) to encourage bone to grow onto the implant, creating a strong, living bond.

Resorbable Ceramics: The Temporary Scaffolds

Resorbable ceramics are engineered to perform a temporary function and then safely dissolve, being replaced by the body's own natural tissue.

Materials like Calcium Phosphates are used as bone graft substitutes to fill voids from trauma or surgery. They provide a scaffold for new bone to form and are gradually absorbed by the body as the healing process completes.

Understanding the Trade-offs

While ceramics offer powerful advantages, they are not without limitations. Acknowledging these trade-offs is essential for proper material selection and engineering design.

The Challenge of Brittleness

The primary drawback of ceramics is their brittleness. While exceptionally hard, they are more susceptible to catastrophic fracture from a sudden, sharp impact compared to metals, which tend to bend or deform.

Modern medical ceramics, like zirconia-toughened alumina, have been engineered to greatly improve fracture toughness, but it remains a fundamental design consideration.

Manufacturing Complexity and Cost

Creating ceramic medical components is a highly technical process. It involves processing ultra-pure powders and firing them at very high temperatures in a process called sintering, as noted for alumina.

This complex manufacturing makes ceramic components more expensive and difficult to produce than their metal equivalents, which can often be cast or machined more easily.

Making the Right Choice for Your Goal

The selection of a ceramic material is driven entirely by the desired medical outcome.

- If your primary focus is creating a long-lasting, high-load joint replacement: Bioinert ceramics like alumina and zirconia are the industry standard for their superior wear resistance and biocompatibility.

- If your primary focus is stimulating bone repair or filling a void: Bioactive or resorbable ceramics like hydroxyapatite are used to integrate with and encourage natural tissue growth.

- If your primary focus is a permanent dental restoration: Zirconia and other dental ceramics offer an unmatched combination of strength, longevity, and aesthetics.

By selecting the right class of ceramic, medical professionals can provide solutions that are not just tolerated by the body, but in many cases, actively work with it to heal.

Summary Table:

| Property | Key Benefit | Common Applications |

|---|---|---|

| Biocompatibility | Minimizes immune response & rejection | Hip/Knee Implants, Dental Crowns |

| Wear Resistance | Extends implant lifespan, reduces debris | Joint Replacement Surfaces |

| Chemical Inertness | Prevents corrosion & ion release | Long-term Surgical Implants |

| Bioactivity | Promotes bone integration & growth | Bone Graft Substitutes, Coatings |

Need reliable, high-performance ceramics for your medical or laboratory applications? KINTEK specializes in premium lab equipment and consumables, including materials crucial for developing and testing advanced medical ceramics. Let our expertise support your innovation—contact us today to discuss your specific needs!

Visual Guide

Related Products

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Boron Nitride (BN) Ceramic Rod for High Temperature Applications

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

People Also Ask

- How long does ceramic insulation last? Unlock 20+ Years of Performance

- What are the seven classifications of ceramic materials? A Guide to Selecting the Right Material

- What is the maximum operating temperature of alumina? The Critical Role of Purity and Form

- Which is harder silicon carbide or tungsten carbide? Discover the Key to Material Selection

- How do high-purity alumina washers function in electrochemical tests? Ensure Isolation in Supercritical Water Research

- What is the significance of ceramic materials like SiC and Al2O3 in electric cracking reactors? Boost Yield and Heat Efficiency

- Why must ceramic fiber precursors be processed at 1350°C? Mastering Sintering for High-Strength Ceramics

- What is the effect of heating rate on sintering mechanism of alumina nanoparticles? Control Density and Strength