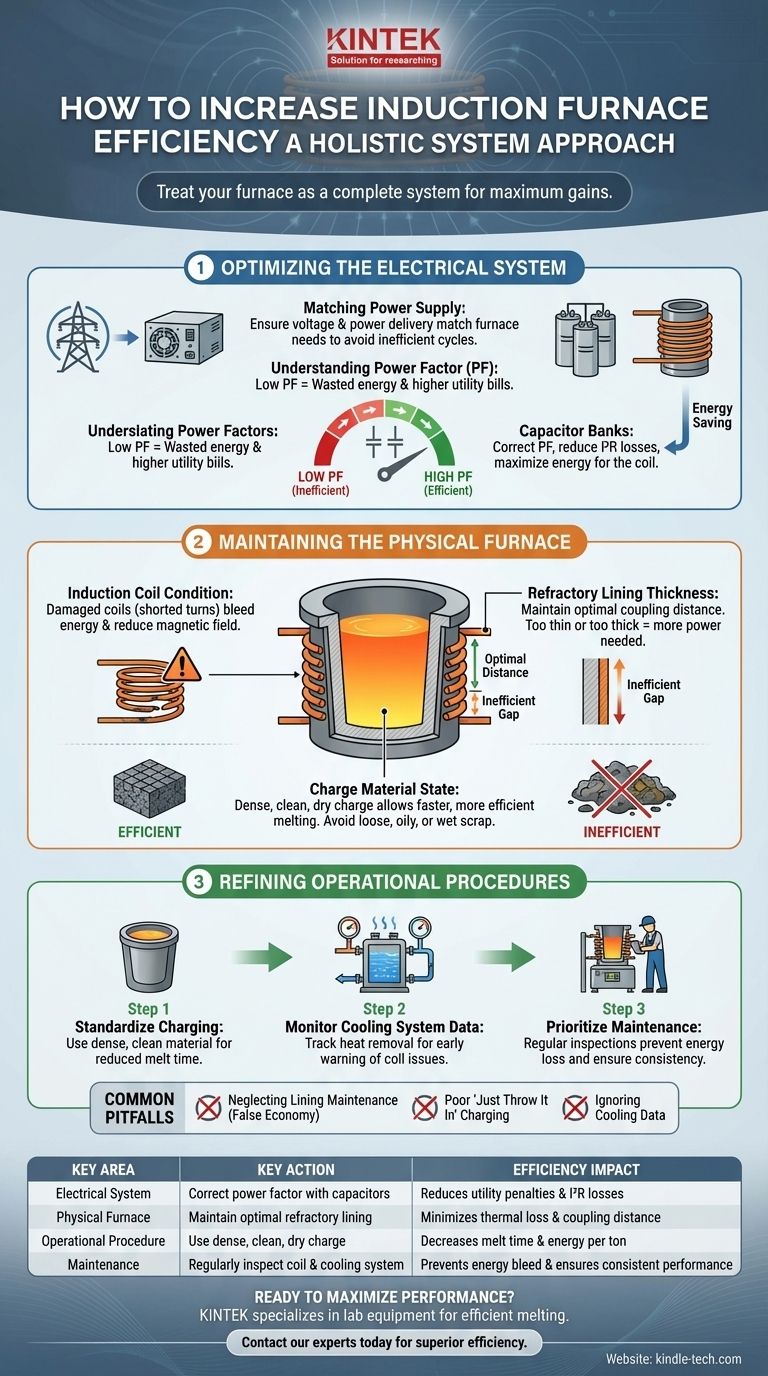

To increase the efficiency of your induction furnace, you must treat it as a complete system, not just a single piece of equipment. The most significant gains come from optimizing the electrical power delivery, maintaining the physical condition of the furnace itself, and refining your operational procedures to minimize wasted energy.

True induction furnace efficiency is a holistic process. It involves a disciplined approach to managing the electrical system, the physical components, and the operational workflow to minimize every form of thermal, electrical, and procedural waste.

Optimizing the Electrical System

The journey of energy from the grid to the molten metal is where the first major efficiency losses occur. A well-tuned electrical system is the foundation of an efficient melting operation.

Matching Power Supply to Your Needs

Your power supply must be correctly sized for your furnace and production demands. An undersized unit will constantly struggle, leading to longer melt times and significant energy waste as it operates outside its ideal efficiency curve.

Ensuring your supply can deliver the required voltage and power is the first critical check. This guarantees the furnace has the energy it needs to melt metal effectively without prolonged, inefficient heating cycles.

Understanding Power Factor

Power factor is a measure of how effectively your furnace uses the electrical current supplied to it. A low power factor means you are drawing more current from the grid than you are actually using to perform work, resulting in higher utility bills and heat loss in your cables.

Most utilities penalize industrial users for poor power factor, making this a direct and often hidden operational cost.

The Critical Role of Capacitors

Capacitor banks are used to correct a low power factor. They act as a local reservoir of reactive energy, reducing the amount of current your system needs to draw from the grid.

Well-maintained and properly sized capacitors are essential for minimizing electrical losses (known as I²R losses) and ensuring the maximum amount of supplied energy is available for the induction coil.

The Physical Furnace: Where Energy Becomes Heat

The furnace itself is where electrical energy is converted into useful heat. The condition and configuration of its core components have a direct and immediate impact on efficiency.

The Induction Coil

The induction coil creates the magnetic field that heats the metal. Any damage, such as shorted turns from debris or insulation failure, creates an electrical short circuit. This drastically reduces the coil's ability to generate a focused magnetic field, bleeding energy and reducing melting performance.

The Refractory Lining

The refractory lining is one of the most critical factors in daily efficiency. Its thickness determines the distance between the coil and the metal charge—a space known as the coupling distance.

A lining that is too worn increases this distance, weakening the magnetic field and requiring more power to melt the charge. Conversely, an overly thick new lining also creates a large gap. There is an optimal thickness that must be maintained.

The Charge Material

The physical state of the metal you load (the charge) is paramount. A densely packed charge with minimal air gaps allows the magnetic field to work on more metal at once, leading to a rapid and efficient melt.

Loose, oily, or wet scrap is highly inefficient. Energy is first wasted burning off contaminants and moisture before it even begins to heat the metal.

Understanding the Trade-offs and Common Pitfalls

Achieving peak efficiency requires avoiding common operational traps that prioritize short-term convenience over long-term performance.

Neglecting Refractory Maintenance

Pushing a refractory lining to its absolute limit to avoid downtime is a false economy. While it may save on labor in the short term, the furnace's electrical efficiency steadily declines as the lining wears, costing far more in wasted energy over time.

Poor Charging Practices

The "just throw it in" approach is a major source of inefficiency. Taking a few extra moments to ensure a dense, well-packed charge pays significant dividends by reducing melt time and overall energy consumption per ton.

Ignoring Cooling System Data

The water-cooling system for the coil and power supply is not just for protection; it's a diagnostic tool. The heat it removes is a direct measurement of the system's electrical and thermal losses. Monitoring this data can provide early warnings of developing problems, like a failing coil turn.

How to Apply This to Your Project

Your specific actions should be guided by your primary operational goal.

- If your primary focus is reducing energy costs: Prioritize power factor correction and diligent refractory monitoring to minimize electrical and thermal waste.

- If your primary focus is increasing production throughput: Focus on optimizing your charging procedures with dense, clean material to minimize melt cycle times.

- If your primary focus is improving melt quality and consistency: Standardize your operational procedures and ensure your power supply delivers consistent energy every cycle.

By treating your furnace as an integrated system, you can systematically turn energy losses into productive output.

Summary Table:

| Key Area | Key Action | Impact on Efficiency |

|---|---|---|

| Electrical System | Correct power factor with capacitors | Reduces utility penalties & I²R losses |

| Physical Furnace | Maintain optimal refractory lining thickness | Minimizes thermal loss & coupling distance |

| Operational Procedure | Use dense, clean, dry charge material | Decreases melt time & energy per ton |

| Maintenance | Regularly inspect induction coil & cooling system | Prevents energy bleed & ensures consistent performance |

Ready to maximize your induction furnace's performance?

KINTEK specializes in the lab equipment and consumables that support efficient melting operations. Whether you're focused on reducing energy costs, increasing production throughput, or improving melt quality, our expertise can help you optimize your entire system.

Contact our experts today to discuss how we can help you achieve superior efficiency and productivity in your laboratory.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys