Choosing the right XRF analyzer requires looking beyond the basic components and focusing on your specific application. The ideal choice is determined by the elements you need to measure, the precision you require, and the environment where you'll be working. It involves matching the analyzer's X-ray source, detector, and form factor to your unique analytical challenge.

The best XRF analyzer is not the one with the most features, but the one whose technical capabilities are precisely aligned with your primary analytical need—whether that's sorting scrap metal, ensuring regulatory compliance, or performing quality control on precision alloys.

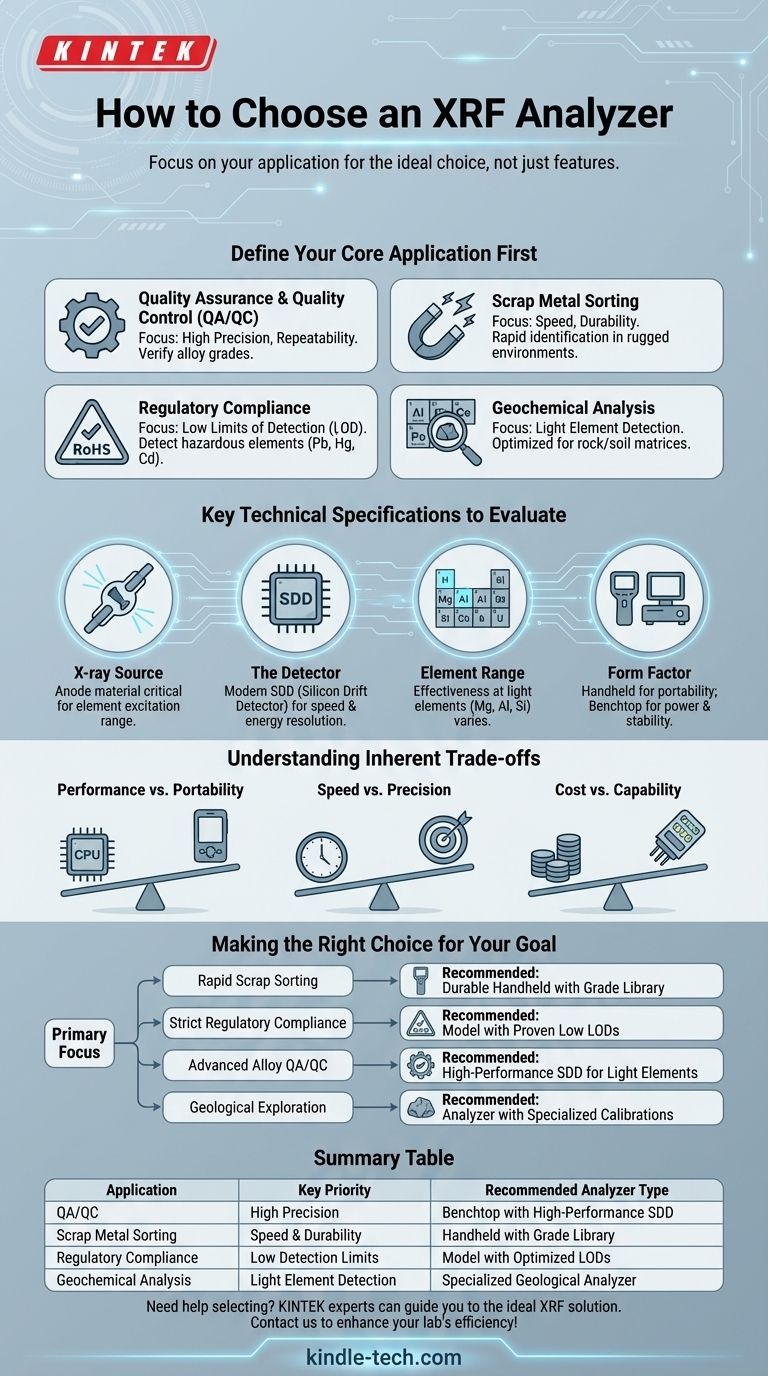

Define Your Core Application First

Before comparing technical specifications, you must clearly define the job the analyzer needs to perform. The demands of different applications dictate which features are essential and which are unnecessary.

Quality Assurance & Quality Control (QA/QC)

In a manufacturing or fabrication environment, QA/QC requires high precision and repeatability. You need to verify alloy grades or confirm the composition of incoming raw materials against a strict specification.

Scrap Metal Sorting

This application prioritizes speed and durability. The goal is to rapidly and positively identify different types of metals in a rugged environment, often with less emphasis on measuring trace elements with extreme precision.

Regulatory Compliance

For applications like RoHS (Restriction of Hazardous Substances), the key is the ability to detect specific hazardous elements like lead (Pb), mercury (Hg), and cadmium (Cd) at very low levels. The analyzer's Limits of Detection (LOD) are the most critical factor here.

Geochemical Analysis

In mining or environmental testing, the focus is often on detecting light elements (like magnesium, aluminum, and silicon) in rock or soil matrices. This requires specialized hardware and software calibrations.

Key Technical Specifications to Evaluate

Once you know your application, you can assess the hardware components that directly impact performance. These specifications are the technical foundation for meeting your goal.

The X-ray Source

The X-ray tube's anode material (the target that emits X-rays) is critical. Different materials are optimized to excite different ranges of elements on the periodic table, directly affecting performance.

The Detector

The detector is the heart of the analyzer. Modern Silicon Drift Detectors (SDD) are the standard, offering superior speed and energy resolution compared to older Si-PIN diode detectors. An SDD is essential for accurately measuring light elements.

Element Range

All XRF analyzers can measure elements from magnesium (Mg) to uranium (U). However, their effectiveness at detecting lighter elements (Mg, Al, Si, P, S) varies dramatically based on the quality of the X-ray source and detector.

Form Factor (Handheld vs. Benchtop)

Handheld XRF analyzers provide incredible portability for in-field testing and point-of-inspection analysis. Benchtop or workstation models offer higher power, more stability, and often better performance for lab-based applications.

Understanding the Inherent Trade-offs

Choosing an analyzer always involves balancing competing priorities. Understanding these trade-offs is key to making an informed, objective decision.

Performance vs. Portability

A portable, handheld unit is ideal for field work but may have limitations in power or cooling compared to a larger benchtop system designed for a controlled lab environment.

Speed vs. Precision

You can often get a faster result by shortening the test time. However, this comes at the cost of precision, as a longer test allows the detector to collect more X-ray counts, improving statistical certainty.

Cost vs. Capability

Analyzers capable of accurately measuring light elements require more advanced (and expensive) detectors and lower-energy X-ray tubes. If you don't need to measure these elements, you can select a more cost-effective model.

Making the Right Choice for Your Goal

To select the ideal analyzer, align your choice with your primary objective. This ensures you invest in the capabilities you truly need.

- If your primary focus is rapid scrap sorting: Prioritize a durable, handheld analyzer with a simple user interface and a comprehensive grade library.

- If your primary focus is strict regulatory compliance: Choose a model with proven low limits of detection for the specific hazardous elements you must control.

- If your primary focus is advanced alloy QA/QC: Invest in an analyzer with a high-performance SDD to ensure precise measurement of light elements like magnesium, aluminum, and silicon.

- If your primary focus is geological exploration: Select an analyzer with calibrations and hardware specifically optimized for light element detection in geological matrices.

By focusing on your application first, you transform a complex technical choice into a clear, strategic decision.

Summary Table:

| Application | Key Priority | Recommended Analyzer Type |

|---|---|---|

| QA/QC | High Precision | Benchtop with High-Performance SDD |

| Scrap Metal Sorting | Speed & Durability | Handheld with Grade Library |

| Regulatory Compliance | Low Detection Limits | Model with Optimized LODs |

| Geochemical Analysis | Light Element Detection | Specialized Geological Analyzer |

Need help selecting the right XRF analyzer for your specific application? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can guide you to the ideal XRF solution for your unique analytical challenges, whether you're focused on QA/QC, scrap sorting, regulatory compliance, or geochemical analysis. Contact us today to discuss your requirements and discover how our solutions can enhance your lab's efficiency and accuracy!

Visual Guide

Related Products

- Customizable XRD Sample Holders for Diverse Research Applications

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- How does pressure affect hydraulic system? Mastering Force, Efficiency, and Heat

- Why is a laboratory hydraulic press used to compress powders into pellets? Enhance Solid-State Reaction Kinetics

- What are the components of hydraulic machines? Master the Core System for Maximum Power

- What are the potential hazards in a hydraulic press? Understanding the Risks of Crushing, Injection, and Failure

- Why was the hydraulic press invented? To Solve the Industrial Revolution's Force Problem

- What is the purpose of a laboratory hydraulic press for LATP electrolyte pellets? Achieve Optimal Density & Conductivity

- What is the function of a laboratory hydraulic press and a 15 mm circular mold? Create Dense Oxygen Membrane Green Bodies

- How does a hydraulic press generate force? Unlocking the Power of Hydraulic Pressure