To clean a quartz furnace tube, the method depends on whether you are cleaning the interior or exterior. For the exterior, you can use a mild solution of four parts water to one part muriatic acid, followed by a thorough water rinse and drying with a soft cloth. For the interior, the primary goal is to remove residual substances without damaging the quartz, which often involves preventative measures and targeted cleaning based on the specific contaminant.

Cleaning a quartz furnace tube is less about a single universal procedure and more about a disciplined maintenance strategy. The best approach prioritizes preventing contamination in the first place, as this is the most effective way to ensure experimental integrity and extend the life of the tube.

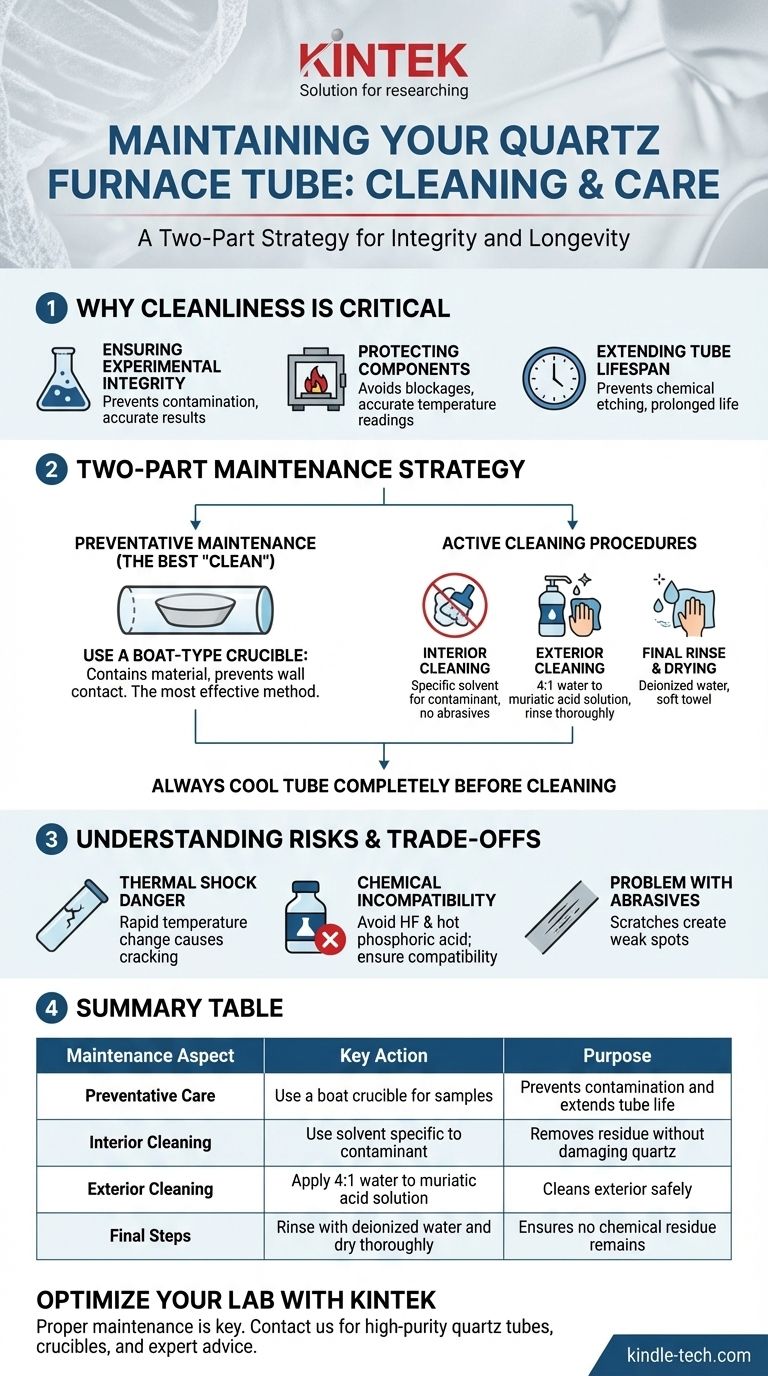

Why Cleanliness is Critical for Your Furnace Tube

A clean quartz tube is not just for appearance; it is fundamental to the function and reliability of the entire furnace system. Neglecting its condition can have direct consequences on your work.

Ensuring Experimental Integrity

The quartz tube serves as the reaction chamber. Any residual substances left over from previous runs can become contaminants, reacting with your new materials and compromising the accuracy of your results.

Protecting Furnace Components

Debris buildup, especially near the ends of the tube, is not inert. It can block the gas flow paths or obstruct internal thermocouples, leading to inaccurate temperature readings and poor atmospheric control.

Extending the Tube's Lifespan

Quartz (SiO2) is robust but not indestructible. Allowing materials to be heated in direct contact with the tube wall risks a chemical reaction, especially at high temperatures. This can etch and weaken the tube, eventually leading to failure.

A Two-Part Strategy for Tube Maintenance

Effective maintenance is a combination of proactive prevention and reactive cleaning. Prioritizing prevention will significantly reduce the need for aggressive cleaning procedures.

Part 1: Preventative Maintenance (The Best "Clean")

The easiest way to keep a tube clean is to stop it from getting dirty. This involves placing your sample materials in a separate container within the tube.

Use a boat-type crucible or a similar sample holder. This contains the material, preventing it from ever touching the walls of the quartz tube, which is the single most effective way to maintain cleanliness and prolong tube life.

Part 2: Active Cleaning Procedures

When active cleaning is necessary, always ensure the tube has cooled completely to room temperature before introducing any liquids to prevent thermal shock, which can crack the quartz.

Cleaning the Interior

Removing internal residue is critical. The first step is to mechanically remove any loose debris. For adhered films or residues, you must choose a solvent that will dissolve the specific contaminant without harming the quartz. This often requires knowledge of the materials used in the furnace.

Cleaning the Exterior

For general exterior cleaning, a 4:1 solution of water to muriatic acid (hydrochloric acid) can be effective. Always wear appropriate personal protective equipment (gloves, goggles) when handling acid. Apply the solution with a cloth, gently wipe the surface, and then rinse it off completely with clean water.

Final Rinse and Drying

After any chemical cleaning, a thorough rinse with deionized water is crucial to remove any remaining cleaning agents. Dry the tube completely with a soft, lint-free towel before returning it to service.

Understanding the Risks and Trade-offs

Improper cleaning can cause more harm than good. Understanding the limitations and potential dangers is essential for protecting your equipment.

The Danger of Thermal Shock

Introducing a cold cleaning liquid to a hot or even warm quartz tube is a primary cause of failure. The rapid temperature change creates immense stress in the material, causing it to crack. Always wait for the tube to cool completely.

The Risk of Chemical Incompatibility

While quartz is highly resistant to most acids, it can be attacked by certain substances like hydrofluoric acid (HF) and hot phosphoric acid. Never use a chemical cleaner unless you are certain it is compatible with quartz and effective for your specific contaminant.

The Problem with Abrasives

Avoid scrubbing the inside of the tube with abrasive pads or powders. Scratches on the quartz surface act as stress concentration points, creating weak spots that are more likely to fail under thermal or mechanical stress during operation.

Making the Right Choice for Your Goal

Your maintenance approach should align with your operational needs and the condition of the tube.

- If your primary focus is routine, daily use: Always use a crucible for your samples and visually inspect and remove any loose debris from the tube after each cooldown.

- If your primary focus is removing a specific internal film: Identify the contaminant from your process and research a compatible solvent to dissolve it, then rinse thoroughly.

- If your primary focus is long-term equipment health: Make it a rule to never clean a tube until it is at room temperature and always perform a final rinse with high-purity water.

Properly maintaining your quartz furnace tube is a direct investment in the reliability and accuracy of your work.

Summary Table:

| Maintenance Aspect | Key Action | Purpose |

|---|---|---|

| Preventative Care | Use a boat crucible for samples | Prevents contamination and extends tube life |

| Interior Cleaning | Use solvent specific to contaminant | Removes residue without damaging quartz |

| Exterior Cleaning | Apply 4:1 water to muriatic acid solution | Cleans exterior safely |

| Final Steps | Rinse with deionized water and dry thoroughly | Ensures no chemical residue remains |

Ensure your lab's furnace tubes operate at peak performance with KINTEK's expertise. Proper maintenance is key to experimental accuracy and equipment longevity. Whether you need high-purity quartz tubes, compatible crucibles, or expert advice on cleaning procedures, KINTEK is here to support your laboratory needs. Contact us today to discuss how our lab equipment and consumables can enhance your processes and protect your investments.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What factors influence the general design of a tube furnace? Match Your Process with the Perfect System

- What is the pressure on a tube furnace? Essential Safety Limits for Your Lab

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- What is the ceramic tube high temperature? From 1100°C to 1800°C, Choose the Right Material

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness