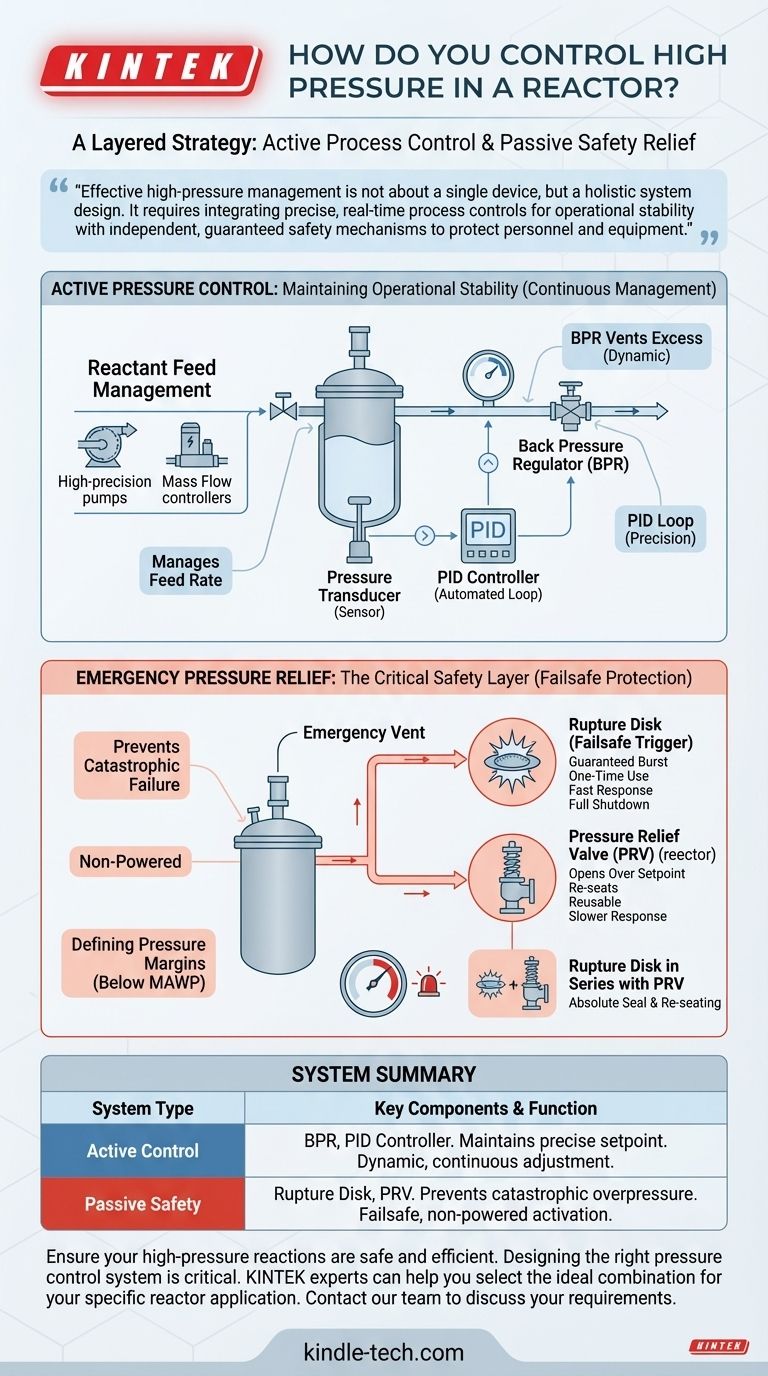

Controlling high pressure in a reactor is achieved through a layered strategy that combines two distinct types of systems. The first is an active process control system, such as a back pressure regulator, which continuously manages pressure during normal operation. The second is a passive safety relief system, such as a rupture disk or relief valve, which acts as a critical failsafe to prevent catastrophic overpressurization in an emergency.

Effective high-pressure management is not about a single device, but a holistic system design. It requires integrating precise, real-time process controls for operational stability with independent, guaranteed safety mechanisms to protect personnel and equipment.

Active Pressure Control: Maintaining Operational Stability

Active control systems are the primary tools used to maintain the desired pressure setpoint during a chemical process. They are dynamic and designed for continuous adjustment.

The Role of the Back Pressure Regulator (BPR)

A back pressure regulator is the most common device for active pressure control. It is essentially a specialized valve installed on the reactor's outlet line.

The BPR works by sensing the upstream pressure within the reactor. It remains closed until the pressure reaches a specified setpoint, at which point it opens just enough to vent excess gas or liquid, thereby maintaining the desired pressure.

Automated Control with PID Loops

For high-precision applications, the BPR is often managed by an automated control loop. A pressure transducer (sensor) inside the reactor sends a continuous signal to a PID controller (Proportional-Integral-Derivative).

The controller compares the actual pressure to the desired setpoint and automatically adjusts the BPR's opening. This creates a highly stable environment, compensating for pressure changes caused by temperature shifts or gas evolution from the reaction.

Managing Reactant Feed Rates

In some systems, pressure is also controlled by manipulating the inlet flow. By using high-precision pumps or mass flow controllers, you can carefully manage the rate at which gaseous or liquid reactants are introduced, thereby controlling the rate of pressure build-up.

Emergency Pressure Relief: The Critical Safety Layer

While active systems manage operational pressure, emergency relief systems are designed for one purpose: to prevent a catastrophic failure if the pressure unexpectedly exceeds the reactor's safe limits. These are passive, non-powered devices.

Rupture Disks: The Failsafe Trigger

A rupture disk is a precision-engineered metal diaphragm designed to burst at a specific, predetermined pressure. It provides a non-mechanical, guaranteed method of relieving pressure.

Once a rupture disk bursts, it cannot be reset. The entire contents of the reactor are vented, and the process must be shut down to replace the disk. This makes it an ideal "last resort" safety device.

Pressure Relief Valves (PRVs): The Re-seating Protector

A pressure relief valve uses a spring-loaded mechanism to open when pressure exceeds its setpoint. Unlike a rupture disk, a PRV will close again once the pressure drops back to a safe level.

This makes PRVs suitable for scenarios where minor, temporary overpressure events might occur. They can prevent a full process shutdown, but are more mechanically complex than a rupture disk.

Combining Disks and Valves

A common and highly reliable strategy is to install a rupture disk in series with a pressure relief valve. The disk is placed between the process and the valve.

This configuration protects the valve's mechanical components from corrosive process fluids, prevents minor leaks through the valve seat, and provides an absolute seal until a true overpressure event occurs.

Understanding the Trade-offs

Choosing the right control and safety strategy requires understanding the functional differences and operational consequences of each component.

Rupture Disks vs. Relief Valves

A rupture disk offers a faster response and a guaranteed, leak-proof seal before activation. However, its activation results in a complete process shutdown and requires manual replacement.

A pressure relief valve is reusable and can manage minor pressure spikes without interrupting the entire process. Its downsides include a slower response time and the potential for leaks or failure to re-seat perfectly after activation.

The Cost of an Emergency Vent

The activation of any emergency relief device is a significant event. It often results in the total loss of the reaction batch, which can be extremely expensive. This underscores the importance of a well-designed active control system to prevent nuisance trips of the safety system.

Defining Pressure Margins

A critical design parameter is the pressure margin. The setpoint for the emergency relief device must be safely above the normal operating pressure but below the reactor's Maximum Allowable Working Pressure (MAWP). A tight margin risks unnecessary shutdowns, while a wide margin could risk vessel integrity if active controls fail.

Designing Your Pressure Control Strategy

Your choice of components should be dictated by your process goals, the nature of your chemistry, and your tolerance for risk and downtime.

- If your primary focus is process stability and repeatability: Prioritize a high-quality automated back pressure regulator with a responsive PID control loop for fine-tuned active management.

- If your primary focus is absolute safety with highly energetic or toxic materials: Use a rupture disk as your primary relief device, as it provides a guaranteed, fast-acting release.

- If your primary focus is managing frequent, minor pressure fluctuations without shutdown: A standalone pressure relief valve is a suitable choice, provided the process fluids are not corrosive to the valve's internal parts.

- If your primary focus is balancing safety with operational reliability: A combination of a rupture disk protecting a pressure relief valve offers the best of both worlds—a perfect seal and re-seating capability.

A layered approach, combining active control for stability with passive safety for protection, is the cornerstone of safe and effective high-pressure reactor operation.

Summary Table:

| System Type | Key Components | Primary Function | Key Characteristic |

|---|---|---|---|

| Active Control | Back Pressure Regulator (BPR), PID Controller | Maintains precise pressure setpoint during operation | Dynamic, continuous adjustment |

| Passive Safety | Rupture Disk, Pressure Relief Valve (PRV) | Prevents catastrophic overpressure in an emergency | Failsafe, non-powered activation |

Ensure your high-pressure reactions are safe and efficient. Designing the right pressure control system is critical for your lab's success and safety. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the ideal combination of back pressure regulators, rupture disks, and relief valves for your specific reactor application.

Contact our team today to discuss your high-pressure reactor requirements and build a safer, more reliable process.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

People Also Ask

- Why is high-pressure nitriding equipment with a dual-pressure balance structure utilized? Boost Speed and Hardness

- What are the technical advantages of using an HTC reactor for biochar? Optimize Wet Biomass Processing

- Why is manual adjustment of back-pressure regulators preferred in SCWG? Gain Precision in Supercritical Research

- Why is the application of high-pressure reactors critical in CO2 hydrogenation to methanol? Boost Yield and Efficiency

- Why are vacuum pumps and nitrogen bubbling devices used to pre-treat high-pressure reactors? Ensure Pure Test Results

- What role do high-pressure reactors and laboratory ovens play in hematite synthesis? Unlock Hydrothermal Precision

- How do high-pressure reactors contribute to corrosion resistance evaluation? Simulating Deep Geological Disposal

- Why are corrosion-resistant chemical reactors essential for the hydrometallurgical leaching of platinum?