The KBr pellet procedure is a standard method for preparing solid samples for Fourier-Transform Infrared (FTIR) spectroscopy. It involves meticulously grinding a small amount of your sample with pure potassium bromide (KBr) powder, placing the mixture into a die, and applying high pressure with a hydraulic press to form a thin, transparent disc suitable for analysis.

The key to a successful KBr pellet is not the press itself, but the preparation that precedes it. Achieving a high-quality, reproducible spectrum hinges on the purity of your KBr, the complete elimination of moisture, and the thoroughness of your grinding technique.

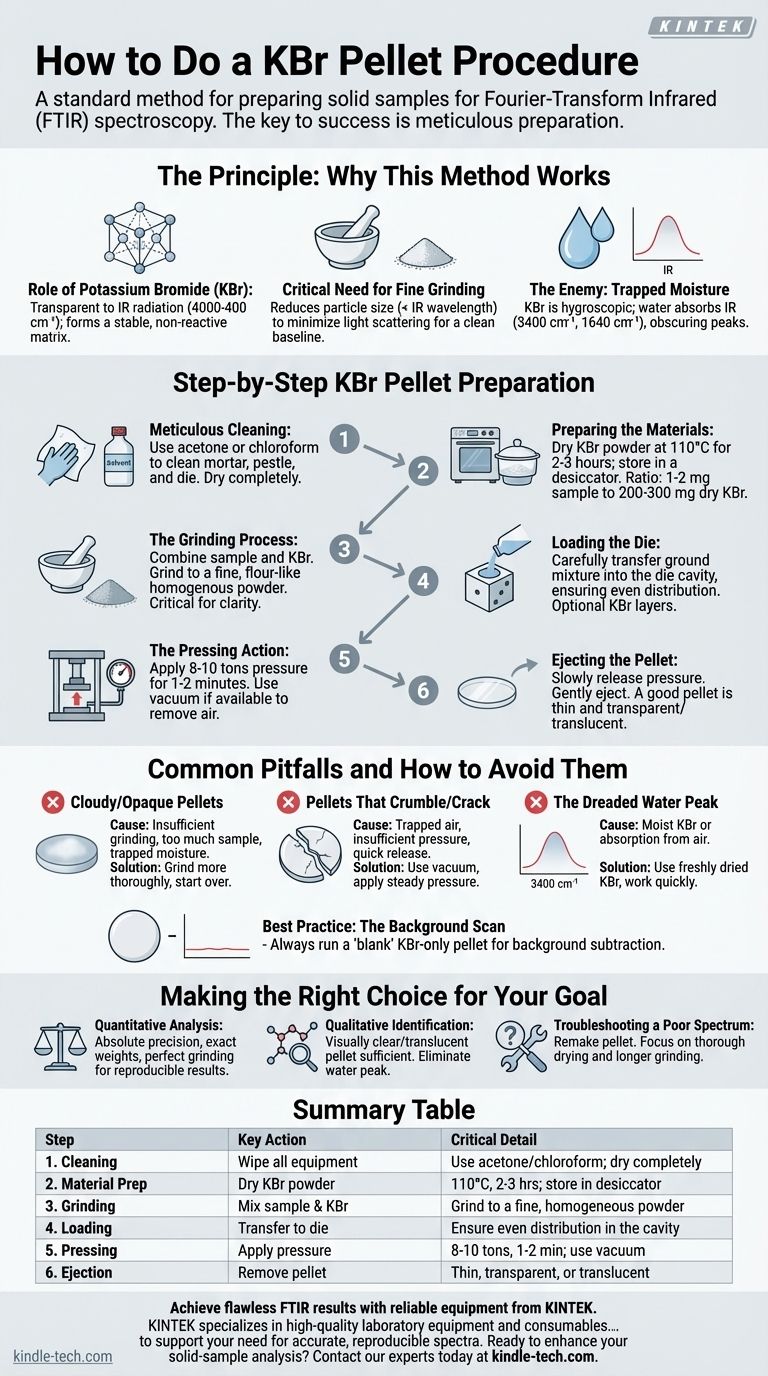

The Principle: Why This Method Works

To obtain a clean spectrum, infrared light must pass through your sample without scattering. The KBr pellet method transforms a solid, often opaque, sample into an IR-transparent medium.

The Role of Potassium Bromide (KBr)

Potassium bromide is used because it is transparent to infrared radiation in the typical analysis range (4000-400 cm⁻¹) and has a refractive index similar to many organic compounds when compressed. It acts as a stable, non-reactive matrix that holds your sample particles in place.

The Critical Need for Fine Grinding

Large sample particles scatter infrared light, causing a sloped, noisy baseline and inaccurate spectral peaks. Grinding the sample with KBr reduces the particle size to less than the wavelength of the IR light, minimizing this scattering effect and ensuring the light is absorbed by the sample, not deflected.

The Enemy: Trapped Moisture

Water (H₂O) is a very strong infrared absorber, showing broad, intense peaks around 3400 cm⁻¹ and 1640 cm⁻¹. Because KBr is hygroscopic (it readily absorbs moisture from the air), any contamination will obscure important regions of your spectrum, potentially masking key functional groups in your sample.

Step-by-Step KBr Pellet Preparation

Follow these steps precisely to produce a high-quality pellet. Assume a standard 13 mm die, but the principles apply to all sizes.

Step 1: Meticulous Cleaning

Before you begin, all equipment must be perfectly clean and dry. Use a solvent like acetone or chloroform to thoroughly wipe the mortar, pestle, and all parts of the pellet die. Dry them completely with a clean tissue.

Step 2: Preparing the Materials

Use only spectroscopic grade KBr. To remove absorbed moisture, dry the KBr powder in an oven at approximately 110°C for 2-3 hours and store it in a desiccator until use. A typical ratio is 1-2 mg of your solid sample to 200-300 mg of dry KBr.

Step 3: The Grinding Process

Weigh your sample and KBr accurately. Combine them in an agate mortar and grind them with the pestle. The goal is a homogenous, fine powder with the consistency of flour. This is the most critical step for pellet clarity.

Step 4: Loading the Die

Assemble the die set. Carefully transfer the ground sample mixture into the die cavity, ensuring an even distribution. For a cleaner result, you can add a small layer of pure KBr powder before and after adding the sample mixture.

Step 5: The Pressing Action

Place the loaded die into a hydraulic press. Apply pressure slowly and steadily up to 8-10 tons. If your press has a vacuum port, apply a vacuum during pressing to remove trapped air, which helps prevent the pellet from cracking. Hold the pressure for 1-2 minutes.

Step 6: Ejecting the Pellet

Slowly release the pressure from the press. Carefully disassemble the die set and gently eject the finished pellet. A good pellet will be thin and either fully transparent or uniformly translucent.

Common Pitfalls and How to Avoid Them

Troubleshooting is a key part of mastering this technique. Most failures occur due to issues in preparation, not pressing.

Problem: Cloudy or Opaque Pellets

This is the most common issue. It is almost always caused by insufficient grinding, leading to light scattering. It can also be caused by using too much sample or by trapped moisture. The solution is to start over and grind more thoroughly.

Problem: Pellets That Crumble or Crack

A brittle pellet that breaks upon ejection is typically caused by trapped air. Using a vacuum during the pressing stage is the best way to prevent this. It can also result from insufficient pressure or releasing the pressure too quickly.

Problem: The Dreaded Water Peak

If you see a very broad, strong peak around 3400 cm⁻¹, your pellet is contaminated with water. This means your KBr was not dried properly or it absorbed moisture from the air during preparation. Work quickly and always use freshly dried KBr.

Best Practice: The Background Scan

Always prepare a "blank" pellet containing only KBr from the same batch you used for your sample. Run this pellet first to obtain a background spectrum. This allows the FTIR software to subtract any minor absorptions from the KBr itself or atmospheric CO₂ and water vapor, ensuring your final spectrum shows only your sample.

Making the Right Choice for Your Goal

The level of precision required depends entirely on your analytical objective.

- If your primary focus is quantitative analysis: Absolute precision is paramount. You must weigh the sample and KBr exactly and ensure perfect grinding for a uniform pellet to get reproducible results.

- If your primary focus is qualitative identification: A visually clear, translucent pellet is often sufficient for identifying a compound. The most important factor is eliminating the water peak, which can obscure fingerprint regions.

- If you are troubleshooting a poor spectrum: Your first step should be to remake the pellet. Focus on thoroughly drying the KBr and grinding the mixture for longer than you think is necessary.

Mastering the KBr pellet technique is a foundational skill that gives you complete control over the quality and accuracy of your solid-state FTIR measurements.

Summary Table:

| Step | Key Action | Critical Detail |

|---|---|---|

| 1. Cleaning | Wipe all equipment | Use acetone or chloroform; dry completely |

| 2. Material Prep | Dry KBr powder | 110°C for 2-3 hours; store in desiccator |

| 3. Grinding | Mix sample & KBr | Grind to a fine, homogeneous powder |

| 4. Loading | Transfer to die | Ensure even distribution in the cavity |

| 5. Pressing | Apply pressure | 8-10 tons for 1-2 minutes; use vacuum if possible |

| 6. Ejection | Remove pellet | Should be thin, transparent, or uniformly translucent |

Achieve flawless FTIR results with reliable equipment from KINTEK.

Mastering the KBr pellet technique requires precision and the right tools. KINTEK specializes in high-quality laboratory equipment and consumables, including spectroscopic grade KBr, durable pellet dies, and reliable hydraulic presses designed for consistent performance.

Whether your focus is rigorous quantitative analysis or confident qualitative identification, our products are engineered to support your need for accurate, reproducible spectra by helping you avoid common pitfalls like moisture contamination and insufficient grinding.

Ready to enhance your solid-sample analysis? Contact our experts today to find the perfect solution for your laboratory's needs and ensure every pellet you press is a success.

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- Why is a laboratory hydraulic press utilized for electrolyte pelletizing? Unlock High Ionic Conductivity

- What is the use of manual hydraulic press? A Cost-Effective Tool for Lab Sample Preparation

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep

- What is the function of a bench-top laboratory hydraulic press for XRF? Maximize Accuracy in Prosopis juliflora Analysis

- How does a laboratory manual hydraulic press facilitate the FT-IR characterization of catalysts? Master Sample Prep.