To perform the KBr pellet method, you must meticulously mix a very small amount of your solid sample (0.1-1.0%) with pure, dry potassium bromide (KBr) powder. This mixture is then finely ground and compressed under several tons of pressure in a die, often under vacuum, to form a small, transparent disc. This resulting pellet is then placed in the spectrometer for infrared (IR) analysis.

The goal is not simply to make a pellet, but to create a perfectly transparent medium for IR analysis. Success hinges on two critical factors: the absolute removal of moisture from the KBr matrix and achieving a uniform, finely ground mixture to prevent light scattering.

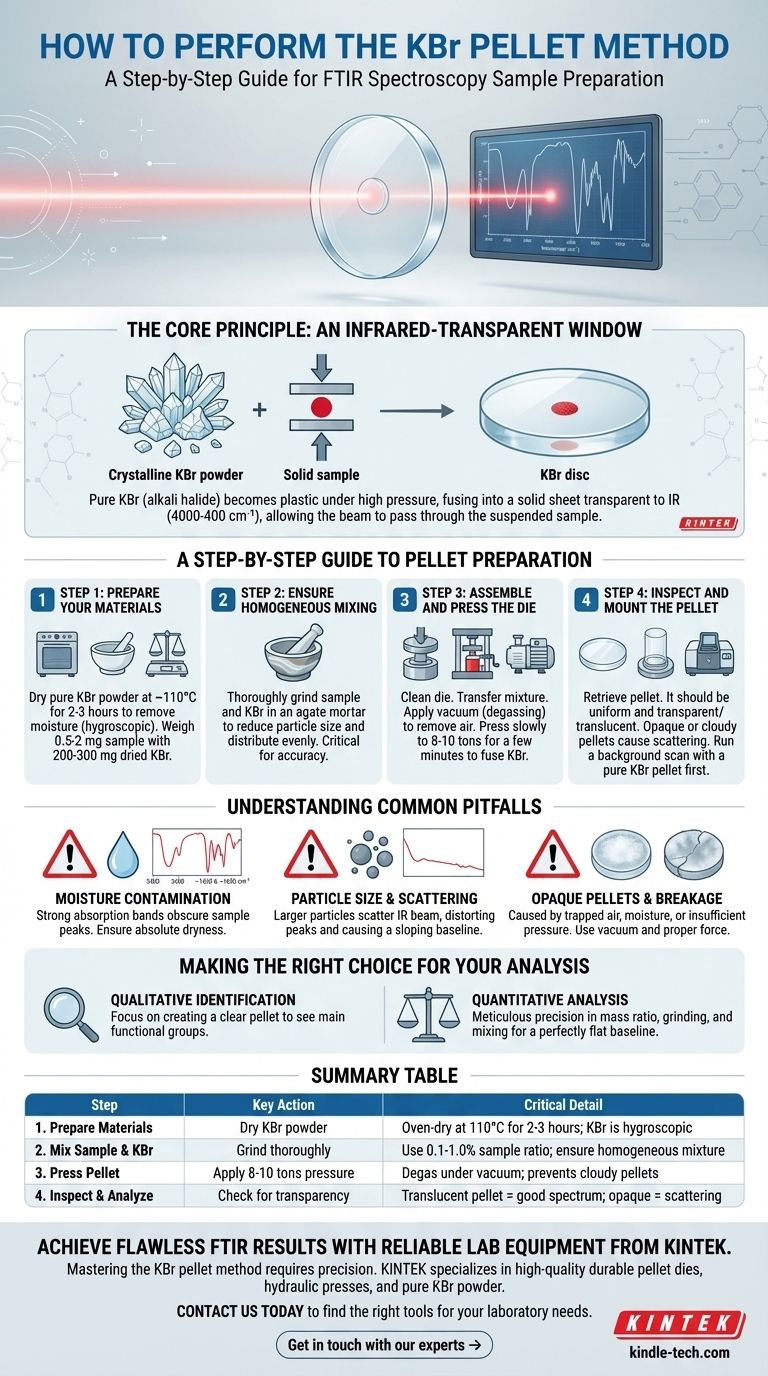

The Core Principle: Why Use KBr?

At its core, the KBr pellet method works because alkali halides like potassium bromide have a unique physical property. While crystalline in their normal state, they become plastic when subjected to high pressure.

An Infrared-Transparent Window

Under pressure, the finely ground KBr powder flows and fuses into a solid, glass-like sheet. Crucially, pure KBr is transparent to infrared radiation across most of the analytical range (4000-400 cm⁻¹).

This process effectively suspends your solid sample particles within an IR-transparent matrix, allowing the spectrometer's IR beam to pass through and generate a spectrum.

A Step-by-Step Guide to Pellet Preparation

Precision at each stage is essential for a high-quality, reproducible spectrum. Rushing any of these steps is the most common source of poor results.

Step 1: Prepare Your Materials

The quality of your raw materials dictates the quality of your final spectrum. KBr is hygroscopic, meaning it readily absorbs moisture from the air.

First, grind pure KBr powder using an agate mortar and pestle. Then, dry the powder in an oven at approximately 110°C for at least two to three hours to eliminate all absorbed water. Store the dried KBr in a desiccator until use.

Next, accurately weigh your materials. A typical ratio is 0.5-2 mg of your solid sample to 200-300 mg of dried KBr.

Step 2: Ensure Homogeneous Mixing

This is the most critical step for spectral accuracy. Pour your weighed sample and the bulk of the KBr into a clean, dry agate mortar.

Grind the mixture thoroughly for several minutes. The goal is to reduce the particle size of the sample and distribute it evenly throughout the KBr matrix. Inadequate mixing will produce a non-representative spectrum.

Step 3: Assemble and Press the Die

First, ensure all parts of your pellet die are impeccably clean. Wipe them down with a solvent like chloroform or acetone and dry them completely.

Assemble the die base and barrel. Carefully transfer the ground sample mixture into the die cavity, distributing it as evenly as possible. Insert the top bolt or plunger.

Transfer the assembled die to a hydraulic press. It is highly recommended to connect the die to a vacuum line to perform degassing. Applying a vacuum for several minutes removes trapped air and residual moisture, which are primary causes of cloudy or fractured pellets.

Apply pressure slowly and steadily up to approximately 8-10 tons for a standard 13 mm die. Hold the pressure for a few minutes to allow the KBr to fully fuse.

Step 4: Inspect and Mount the Pellet

Carefully release the pressure and disassemble the die to retrieve your pellet.

A good pellet should be uniform and transparent or translucent, much like a small piece of glass. If it is opaque, cloudy, or cracked, the spectrum will be poor due to light scattering.

Place the finished pellet into the appropriate sample holder for your FTIR spectrometer and you are ready for analysis.

Understanding the Common Pitfalls

Knowing what can go wrong is key to troubleshooting and perfecting your technique.

The Problem of Moisture Contamination

Water has very strong and broad absorption bands in the infrared spectrum (~3400 cm⁻¹ and ~1630 cm⁻¹). If your KBr is not perfectly dry, these peaks will appear in your spectrum and can easily obscure important peaks from your sample.

The Effect of Particle Size and Scattering

If your sample or KBr is not ground finely enough, the larger particles will scatter the IR beam instead of absorbing it. This results in a sloping baseline (a phenomenon known as the Christiansen effect) and can distort the shape and intensity of your absorption peaks, making quantitative analysis impossible.

Opaque Pellets and Breakage

A cloudy or opaque pellet is almost always caused by one of two things: moisture or trapped air. This is why drying the KBr and applying a vacuum during pressing are not optional steps for high-quality results. Insufficient pressure can also lead to a fragile pellet that crumbles easily.

KBr Oxidation

When drying KBr, avoid rapid or excessively high temperatures. This can cause some of the bromide (KBr) to oxidize into potassium bromate (KBrO₃), which may cause a slight brown discoloration in the pellet.

Performing the Measurement and Background Correction

Before analyzing your sample pellet, you must first run a background spectrum.

Why a Background Scan is Non-Negotiable

A background scan measures the spectrum of everything except your analyte. For this method, the ideal background is a pellet made from pure KBr from the same batch you used for your sample.

This allows the instrument software to subtract absorptions from atmospheric CO₂ and water vapor, as well as any minor impurities or scattering effects from the KBr matrix itself. This ensures the final spectrum shows only the absorptions from your sample.

Making the Right Choice for Your Analysis

Your specific analytical goal should guide the level of rigor you apply to the process.

- If your primary focus is quick qualitative identification: You can prioritize creating a clear pellet to see the main functional group peaks, even if the baseline is not perfectly flat.

- If your primary focus is quantitative analysis: You must be meticulous. Precisely control the sample-to-KBr mass ratio and aim for a perfectly flat baseline by ensuring extremely fine grinding and excellent mixing.

- If you are troubleshooting a failed pellet: If your pellet is cloudy, cracked, or opaque, the most likely culprits are insufficient drying of the KBr or inadequate vacuum during the pressing stage.

Mastering this technique is a matter of systematically controlling moisture and pressure to transform your solid sample into a clear window for infrared analysis.

Summary Table:

| Step | Key Action | Critical Detail |

|---|---|---|

| 1. Prepare Materials | Dry KBr powder | Oven-dry at 110°C for 2-3 hours; KBr is hygroscopic |

| 2. Mix Sample & KBr | Grind thoroughly in agate mortar | Use 0.1-1.0% sample ratio; ensure homogeneous mixture |

| 3. Press Pellet | Apply 8-10 tons pressure under vacuum | Degas to remove air/moisture; prevents cloudy pellets |

| 4. Inspect & Analyze | Check for transparency | Translucent pellet = good spectrum; opaque = scattering |

Achieve flawless FTIR results with reliable lab equipment from KINTEK.

Mastering the KBr pellet method requires precision at every step—especially in moisture control, mixing, and pressing. KINTEK specializes in high-quality lab equipment and consumables, including durable pellet dies, hydraulic presses, and pure, dry KBr powder, designed to help you create perfect pellets for accurate, reproducible spectroscopy.

Contact us today to find the right tools for your laboratory needs and ensure your sample preparation is never a variable in your analysis.

Get in touch with our experts →

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What are the factor affecting pelletization technique? Mastering Material, Process, and Binder Variables

- Why is a laboratory hydraulic press used for 380 MPa pressure? Master Solid-State Electrolyte Densification

- What are the primary functions of the core holder and high-pressure manual pump? Master Stress Simulation for Lab Tests

- What products can be made on a hydraulic press? From Metal Parts to Lab Samples

- What task does a laboratory hydraulic press perform in Fe@C specimen preparation? Optimize Electromagnetic Testing

- Why is pressing force important in sintering? Achieve Denser, Stronger Materials Faster

- What types of hydraulic press systems are used for research? Discover Pellet, Hot, and Isostatic Solutions

- What is a cubic press and how does it function? Master High-Volume, Uniform 3D Compression