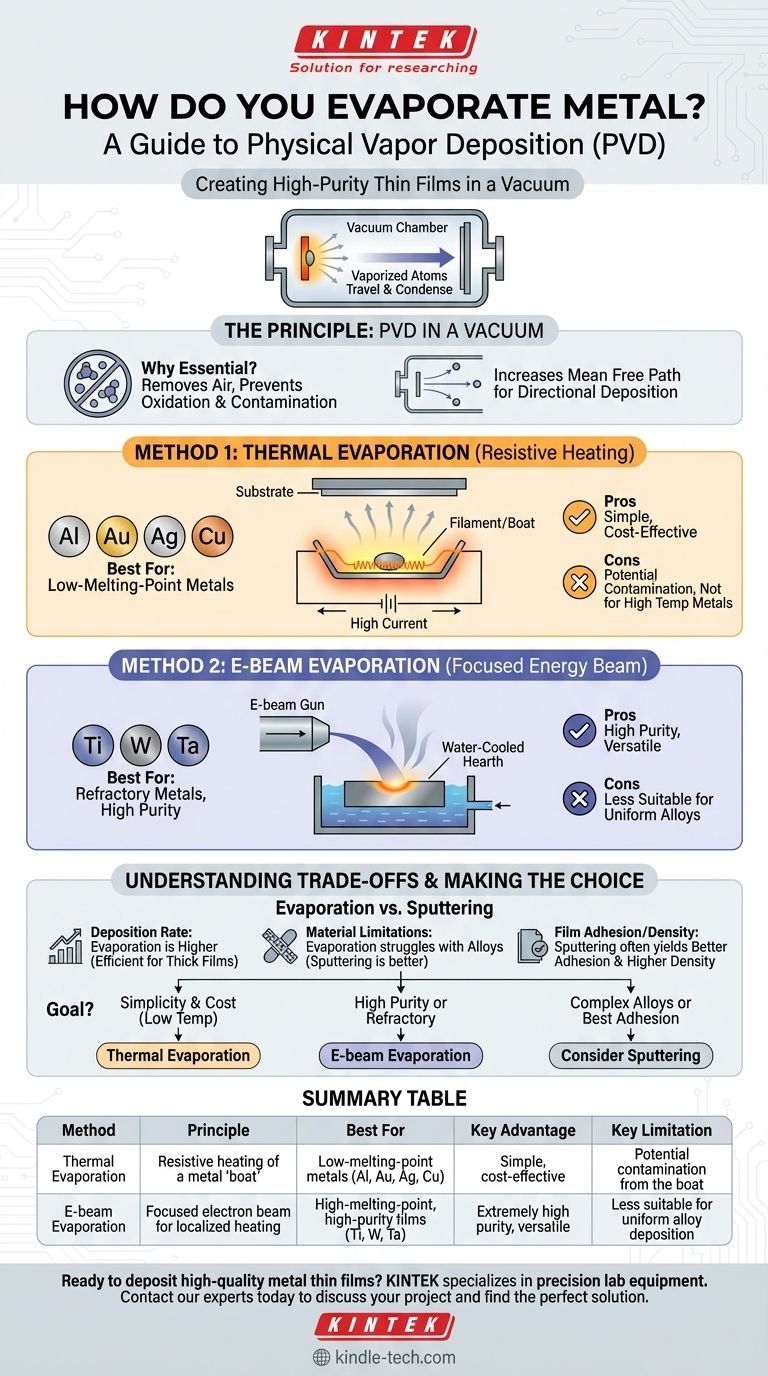

At its core, evaporating metal is a process of heating a source metal inside a high-vacuum chamber until its atoms gain enough thermal energy to vaporize. These vaporized atoms then travel in a straight line and condense onto a cooler surface, known as a substrate, forming an ultra-thin, solid film. This entire process is a form of Physical Vapor Deposition (PVD).

The question isn't just how to turn metal into a gas, but why. The goal is almost always to create a high-purity, uniform thin film on another material. Your choice of evaporation method—thermal or electron-beam—is dictated by the metal's melting point and the purity requirements of your final product.

The Principle: Physical Vapor Deposition in a Vacuum

The entire process of metal evaporation for thin-film coating hinges on one critical environment: a high vacuum.

Why a Vacuum is Essential

A vacuum chamber is pumped down to a very low pressure, removing most of the air molecules. This is non-negotiable for two reasons.

First, it prevents the hot metal vapor from reacting with oxygen or nitrogen in the air, which would form unwanted oxides or nitrides and contaminate the film.

Second, it dramatically increases the mean free path—the average distance a vapor atom can travel before colliding with another gas molecule. In a high vacuum, atoms travel unimpeded from the source to the substrate, ensuring a directional and clean deposition.

Method 1: Thermal Evaporation

Thermal evaporation, often called resistive heating, is the most straightforward method. It is a workhorse for depositing metals with relatively low boiling points.

How It Works: Resistive Heating

The source metal, often in the form of pellets or wire, is placed in a small container called a "boat" or a "filament." This boat is typically made of a refractory material like tungsten, molybdenum, or tantalum.

A very high electrical current is passed through the boat. The boat's natural electrical resistance causes it to heat up intensely, much like the filament in an old incandescent light bulb. This heat is transferred to the source metal, causing it to melt and then evaporate.

Materials and Applications

This method works exceptionally well for metals like Aluminum (Al), Gold (Au), Silver (Ag), and Copper (Cu). It is commonly used for creating reflective coatings on mirrors, electrical contacts in electronics, and decorative coatings.

Key Limitation: Potential Contamination

The primary drawback of thermal evaporation is that the boat material can also evaporate slightly, leading to minor contamination of the deposited film. It is also unsuitable for materials with very high boiling points, as the boat itself would melt or evaporate too quickly.

Method 2: Electron-Beam Evaporation

Electron-Beam (E-beam) Evaporation is a more sophisticated and powerful technique, essential for high-purity films and high-melting-point materials.

How It Works: A Focused Beam of Energy

In an E-beam system, a high-energy beam of electrons is generated and magnetically guided to strike the surface of the source metal, which sits in a water-cooled copper hearth.

This focused beam transfers its kinetic energy directly to a small spot on the source material, causing localized heating and evaporation. Because the rest of the source material and the hearth remain cool, contamination is virtually eliminated.

Materials and Applications

E-beam evaporation is the standard for depositing refractory metals like Titanium (Ti), Tungsten (W), and Tantalum (Ta). It is also used for depositing dielectric materials like silicon dioxide (SiO₂) for optical filters and advanced semiconductor layers.

Key Advantage: Purity and Versatility

Because only the source metal is heated, e-beam evaporation produces films of extremely high purity. It can deposit a much wider range of materials, including those with the highest melting points, giving it far greater process versatility.

Understanding the Trade-offs

Evaporation is not the only PVD technique. It exists alongside sputtering, and choosing between them depends on your specific goals.

Deposition Rate

Evaporation typically offers a much higher deposition rate than sputtering. This makes it more efficient for creating thicker films or for high-throughput manufacturing.

Material Limitations

Thermal evaporation is limited to lower-temperature metals. E-beam evaporation is highly versatile but struggles with the uniform deposition of alloys, as the constituent metals may evaporate at different rates. Sputtering is often superior for depositing complex alloys.

Film Adhesion and Density

Sputtering bombards the substrate with higher-energy atoms compared to evaporation. This generally results in films with better adhesion and higher density. Evaporated films can sometimes be less dense or have more internal stress.

Making the Right Choice for Your Goal

Selecting the correct method is a critical decision based on material, cost, and desired film properties.

- If your primary focus is simplicity and cost for low-temperature metals (like aluminum or gold): Thermal evaporation is your most direct and economical path.

- If your primary focus is high purity or depositing refractory metals (like titanium or tungsten): E-beam evaporation is the necessary and superior choice.

- If your film requires a complex alloy or the absolute best adhesion: You should investigate alternative PVD methods like sputtering.

Understanding these core principles empowers you to select the precise deposition technology that meets your material and performance requirements.

Summary Table:

| Method | Principle | Best For | Key Advantage | Key Limitation |

|---|---|---|---|---|

| Thermal Evaporation | Resistive heating of a metal 'boat' | Low-melting-point metals (Al, Au, Ag, Cu) | Simple, cost-effective | Potential contamination from the boat |

| E-beam Evaporation | Focused electron beam for localized heating | High-melting-point, high-purity films (Ti, W, Ta) | Extremely high purity, versatile | Less suitable for uniform alloy deposition |

Ready to deposit high-quality metal thin films? The right evaporation equipment is critical for achieving the purity, adhesion, and uniformity your research or production demands. KINTEK specializes in precision lab equipment, including thermal and e-beam evaporation systems, to meet your specific laboratory needs. Contact our experts today to discuss your project and find the perfect solution for your thin-film applications.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does electron beam curing work? Achieve Instant, Durable Curing for Industrial Applications

- What is evaporation and sputtering? Choose the Right PVD Method for Your Thin Film Needs

- What is the electron deposition method? Achieve High-Purity Thin Films for Advanced Applications

- What is film thickness uniformity? Achieve Consistent Performance and Higher Yield

- What precautions should be taken during evaporation process? Ensure High-Quality Film Deposition

- What is the process of evaporation coating? A Guide to Thin Film Deposition

- What is the thermal process of evaporation? A Guide to High-Purity Thin Film Deposition

- What is the deposition rate of electron beam evaporation? Unlock Precision Control from 0.1 to 100 nm/min