To make biochar in a muffle furnace, you must place your dried biomass inside a sealed container, such as a crucible with a tight-fitting lid, before heating. This container creates an oxygen-free environment, which is essential for pyrolysis (thermal decomposition without oxygen) to occur. Simply placing biomass directly into the furnace will cause it to combust and turn to ash, not biochar.

The muffle furnace provides the necessary controlled heat, but you must provide the oxygen-limited environment. The success of your biochar production hinges entirely on preventing oxygen from reaching the biomass during the heating and cooling phases.

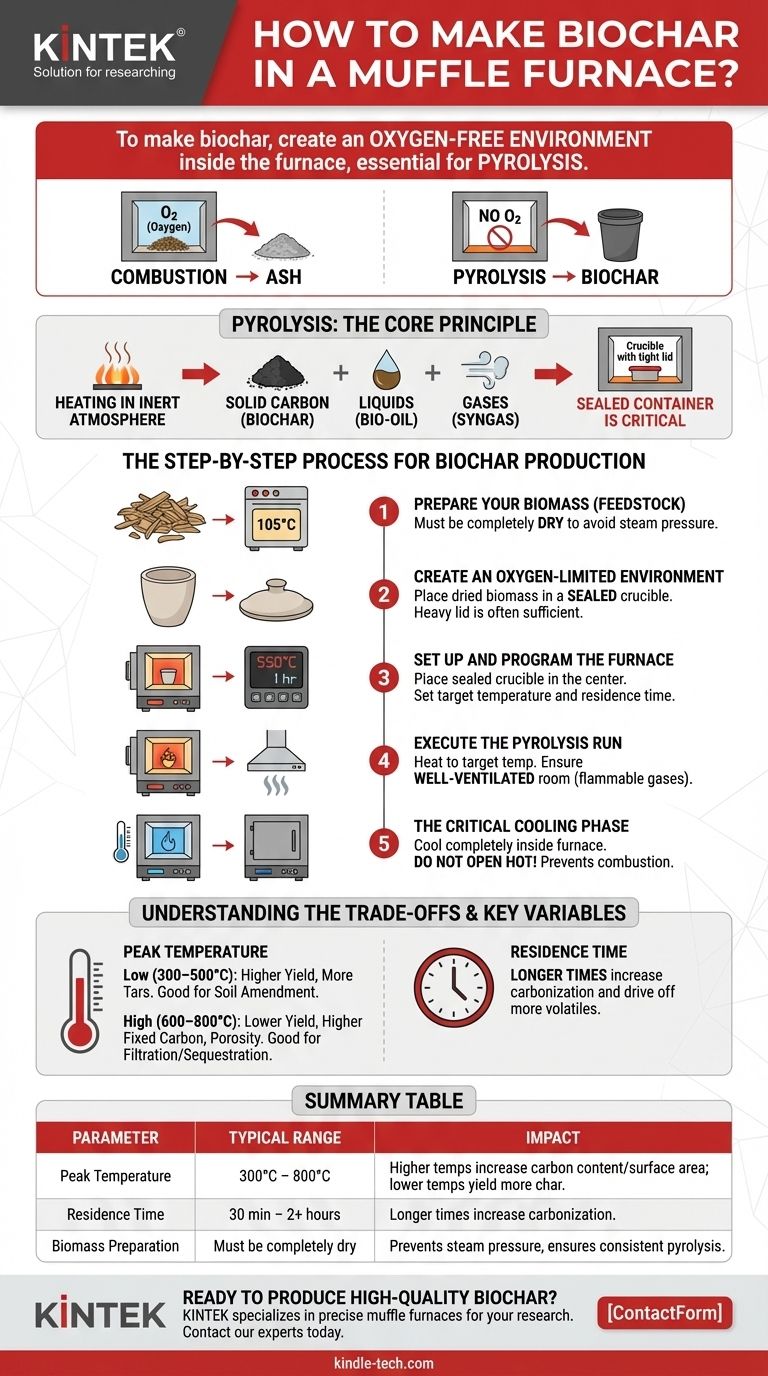

Understanding the Core Principle: Pyrolysis, Not Combustion

To produce high-quality biochar, it's critical to understand the fundamental process you are trying to control within the furnace.

What is Pyrolysis?

Pyrolysis is the thermal decomposition of materials at elevated temperatures in an inert atmosphere. It involves a change in chemical composition and is fundamentally different from burning.

For biochar, you are heating organic material (biomass) until its complex molecules break down into solid carbon (biochar), liquids (bio-oil), and gases (syngas).

Combustion vs. Pyrolysis in a Muffle Furnace

A muffle furnace chamber contains air (and therefore oxygen). If you place biomass directly on the furnace hearth and heat it, the oxygen will cause it to burn. This is combustion, and the result is ash.

To achieve pyrolysis, you must isolate the biomass from the oxygen in the furnace chamber. This is why using a sealed container is the single most important step.

The Step-by-Step Process for Biochar Production

Follow these steps to safely and effectively create biochar using a standard laboratory muffle furnace.

Step 1: Prepare Your Biomass (Feedstock)

Before heating, your biomass must be completely dry. Place your feedstock (wood chips, straw, etc.) in an oven at a low temperature (around 105°C or 221°F) for several hours until its weight stabilizes.

Moisture inside the feedstock will turn to steam, which can build pressure and interfere with the pyrolysis process.

Step 2: Create an Oxygen-Limited Environment

This is the most critical technical step. Place your dried biomass into a ceramic or metal crucible that has a well-fitting lid.

For a tighter seal, you can press the lid on firmly. In advanced applications, a refractory sealant might be used, but a heavy, tight lid is often sufficient for basic production.

Step 3: Set Up and Program the Furnace

Place the sealed crucible in the center of the muffle furnace, ensuring it's stable. Do not let it touch the heating elements.

Close the furnace door and set your target temperature and heating time (residence time). A common starting point is 550°C for 1 hour.

Step 4: Execute the Pyrolysis Run

Turn the furnace on. The controller will indicate that the temperature is rising. As the biomass heats, it will release volatile gases, which may seep from the crucible.

Ensure the furnace is in a well-ventilated room or under a fume hood, as these gases are flammable. Once the target temperature is reached, the furnace will hold it for your set residence time.

Step 5: The Critical Cooling Phase

After the heating cycle is complete, turn the furnace off but leave the door closed. Do not open the furnace or remove the crucible.

The biochar inside is extremely hot and will instantly combust into ash if exposed to the oxygen in the air. You must allow the furnace to cool down completely, often overnight, to a safe temperature (below 100°C) before opening the door and removing your sample.

Understanding the Trade-offs and Key Variables

You can engineer different types of biochar by manipulating two key variables: peak temperature and residence time.

The Role of Peak Temperature

The final temperature directly impacts the biochar's properties.

- Low Temperatures (300–500°C): Produces a higher yield of biochar, but with lower carbon content and more residual tars. This is often better for agricultural soil amendments.

- High Temperatures (600–800°C): Results in a lower yield but produces a biochar with higher fixed carbon, greater porosity, and higher surface area. This is ideal for filtration or carbon sequestration.

The Impact of Residence Time

Residence time is the duration the biomass is held at the peak temperature. Longer times (e.g., 2 hours vs. 30 minutes) will increase the degree of carbonization, driving off more volatiles and increasing the fixed carbon percentage.

How to Apply This to Your Goal

Your production parameters should be dictated by your intended use for the biochar.

- If your primary focus is agricultural soil amendment: Use a lower peak temperature (~450°C) to create a biochar with a higher nutrient content and cation exchange capacity.

- If your primary focus is carbon sequestration or water filtration: Use a higher peak temperature (~700°C) to maximize the fixed carbon content and surface area.

- If your primary focus is experimental research: Start with a baseline (e.g., 550°C for 1 hour) and methodically adjust only one variable at a time to observe its effect on the final product.

By mastering these principles, you can transform a simple muffle furnace into a precise tool for creating custom-engineered biochar.

Summary Table:

| Parameter | Typical Range for Biochar | Impact on Final Product |

|---|---|---|

| Peak Temperature | 300°C - 800°C | Higher temps increase carbon content and surface area; lower temps yield more char. |

| Residence Time | 30 min - 2+ hours | Longer times increase carbonization and drive off more volatiles. |

| Biomass Preparation | Must be completely dry | Prevents steam pressure and ensures consistent pyrolysis. |

Ready to produce high-quality biochar for your research or application?

KINTEK specializes in the precise lab equipment you need for success. Our muffle furnaces offer the exact temperature control and safety features required for reliable pyrolysis. Whether you're developing soil amendments, filtration media, or conducting advanced materials research, we have the solution.

Contact our experts today to find the perfect furnace for your biochar production goals and ensure your process is efficient, safe, and effective.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the safety precautions during heat treatment process? A Guide to Mitigating Thermal, Atmospheric, and Mechanical Hazards

- How does a muffle furnace work? A Guide to Clean, High-Temperature Heating

- Why is it important to hardening a steel? To Achieve Superior Strength and Wear Resistance

- How is melting point affected by heating rate? Avoid Inaccurate Measurements in Your Lab

- What is a muffle furnace for laboratory use? A Guide to Contaminant-Free High-Temperature Processing