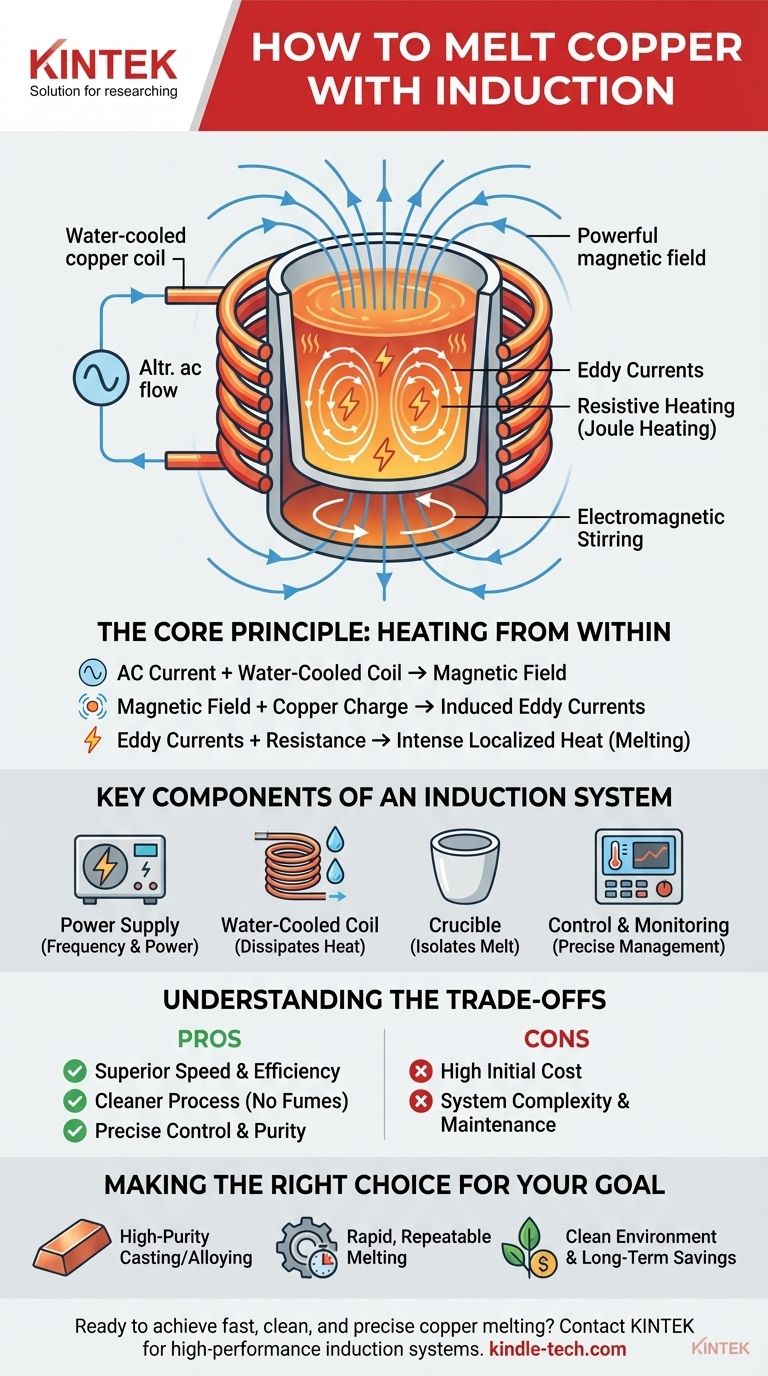

Melting copper with induction is a process of non-contact heating driven by electromagnetic principles. A high-frequency alternating current (AC) is passed through a water-cooled copper coil, which generates a powerful and rapidly changing magnetic field. When copper metal is placed inside this coil, the magnetic field induces strong electrical currents, known as eddy currents, directly within the copper itself. These currents, flowing against the copper's inherent electrical resistance, generate intense, localized heat that quickly brings the metal to its melting point.

The core advantage of induction melting is not just the heat, but the control. By using electromagnetism to heat the copper from within, the process achieves superior speed, energy efficiency, and metallurgical purity compared to conventional methods that rely on external flames or heating elements.

The Core Principle: Heating from Within

Induction melting is fundamentally different from a conventional furnace. Instead of applying external heat and waiting for it to conduct into the metal, induction generates the heat inside the target material.

The Induction Coil and Magnetic Field

The heart of the system is a precisely wound, water-cooled copper coil. A specialized power supply sends a medium-frequency AC current through this coil. This current flow creates a concentrated and dynamic magnetic field in the space contained by the coil.

Inducing Eddy Currents

When conductive material like copper is placed into this magnetic field, the field induces powerful, circulating electrical currents within the copper. These are called eddy currents. The coil acts as the primary of a transformer, and the copper charge effectively becomes a short-circuited secondary.

Resistive Heating Leads to Melting

The induced eddy currents are not "free" to flow; they must overcome the natural electrical resistance of the copper. This struggle generates immense heat (known as Joule or resistive heating). This heating is rapid, uniform, and occurs directly within the metal, causing it to melt efficiently without any direct contact from a heat source.

The Benefit of Electromagnetic Stirring

A unique and critical side effect of this process is electromagnetic stirring. The powerful magnetic forces repel and interact with the molten metal, creating a natural stirring action. This ensures the liquid copper achieves a uniform temperature and a homogenous composition, which is vital for creating high-quality alloys.

Key Components of an Induction System

An induction furnace is more than just a coil. It is a complete system where each component plays a critical role in achieving a controlled, efficient melt.

The Power Supply

This unit, often a medium-frequency generator, converts mains electricity into the high-amperage, specific-frequency AC current required by the induction coil. The power and frequency determine the heating characteristics and efficiency.

The Water-Cooled Coil

The induction coil itself carries enormous electrical current and would quickly melt if not actively cooled. A continuous flow of water through the hollow copper tubing of the coil is essential to dissipate its own resistive heat and maintain structural integrity.

The Crucible

The copper charge is held within a crucible, which is a non-conductive, heat-resistant container typically made of ceramic or graphite. The crucible isolates the molten metal and must be able to withstand extreme thermal shock without contaminating the melt.

Control and Monitoring Systems

Modern systems include components like infrared temperature sensors and controllers. These allow for precise management of the melting process, ensuring the metal reaches the exact target temperature without overheating, which helps minimize metal loss and save energy.

Understanding the Trade-offs

While highly effective, induction melting is not the universal solution for every application. Understanding its specific advantages and limitations is key to making an informed decision.

Superior Efficiency and Speed

Induction is exceptionally fast. The direct internal heating leads to a rapid rise in temperature and significantly higher energy efficiency compared to fuel-fired furnaces, where much of the heat is lost to the furnace walls and exhaust gases.

A Cleaner Process

Because there is no combustion, the process is free of the smoke, dust, and pollutants associated with burning fossil fuels. This results in a cleaner working environment and, more importantly, prevents contaminants from being introduced into the molten copper.

High Initial Cost

The primary drawback of induction systems is their initial capital cost. The sophisticated power supply, water-cooling circuits, and precision coils make them more expensive to purchase and install than a simple gas-fired furnace.

System Complexity

While operation can be simple, the underlying system is complex. Maintenance and repair of the power electronics or cooling systems typically require specialized technical expertise. The crucible is also a consumable item that requires periodic replacement.

Making the Right Choice for Your Goal

Selecting an induction furnace depends entirely on your specific manufacturing or casting objectives.

- If your primary focus is high-purity casting or alloying: Induction is the superior choice because its clean heating process and electromagnetic stirring ensure minimal contamination and a perfectly homogenous final product.

- If your primary focus is rapid, repeatable melting of small-to-medium batches: The speed, precision, and efficiency of induction make it ideal for production environments that value consistency and fast cycle times.

- If your primary focus is a clean work environment and long-term operational savings: Induction provides a fume-free process and significant power savings that can offset the higher initial investment over time.

Ultimately, induction melting empowers you to melt copper with an unmatched combination of speed, cleanliness, and precise control.

Summary Table:

| Key Aspect | Induction Melting Advantage |

|---|---|

| Heating Method | Internal heating via induced eddy currents |

| Speed | Rapid melting due to direct energy transfer |

| Purity | Clean process with no combustion contaminants |

| Control | Precise temperature management and stirring |

| Efficiency | High energy efficiency with minimal heat loss |

Ready to achieve fast, clean, and precise copper melting?

KINTEK specializes in high-performance lab equipment, including induction melting systems designed for superior results. Our solutions offer the speed, purity, and control essential for high-quality casting, alloying, and R&D.

Contact our experts today to find the perfect induction melting system for your laboratory's specific needs and unlock efficient, contaminant-free metal processing.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity

- What functions does a vacuum hot press (VHP) furnace perform? Master Al/EHEA Composite Fabrication

- How does a vacuum hot pressing furnace optimize Ni-Co-Al density? Achieve 97.6% Relative Density via Precision Control

- What are the advantages of using a vacuum hot pressing furnace over HIP? Optimize Fiber-Foil Composite Production

- Why is the vacuum system of a Vacuum Hot Pressing furnace critical for ODS ferritic stainless steel performance?