To prepare a KBr pellet for FTIR analysis, you must intimately mix a very small amount of your solid sample with spectroscopic-grade potassium bromide (KBr) powder. This mixture is then ground into a fine, homogenous dust and compressed under high pressure using a pellet press and die to form a thin, transparent disc suitable for analysis.

The ultimate goal is to create a solid solution where your sample is so finely dispersed within the KBr matrix that the pellet becomes transparent to the infrared beam. Success hinges on three critical factors: meticulous grinding, maintaining an absolutely dry environment, and applying pressure correctly.

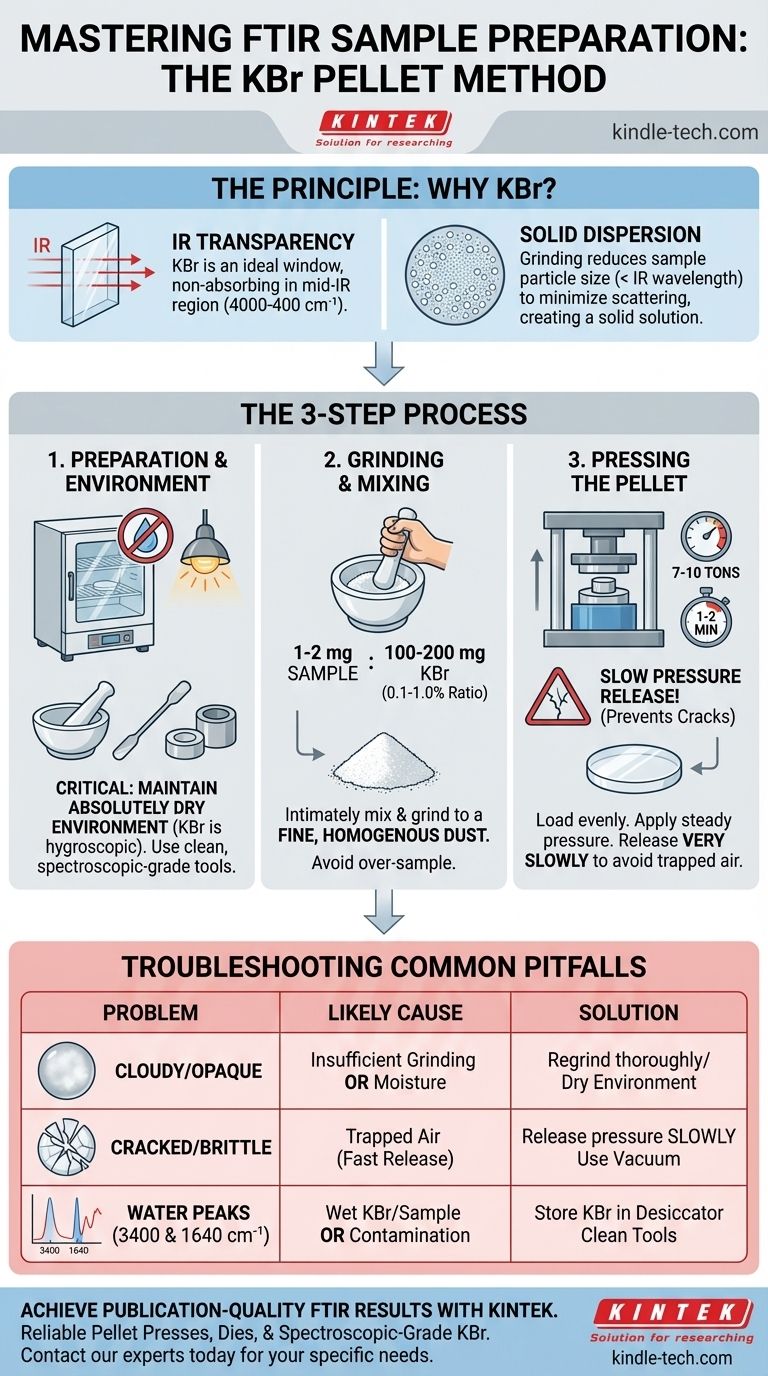

The Principle: Why Use KBr?

Understanding why this method works is key to troubleshooting it. KBr is used because it acts as an ideal window for the infrared light.

IR Transparency

Potassium bromide is a salt that does not absorb light in the mid-infrared region (roughly 4000 to 400 cm⁻¹). This makes it a perfect matrix material, as it allows the spectrometer's IR beam to pass through the pellet and interact only with your sample, not the KBr itself.

Creating a Solid Dispersion

By grinding the sample with KBr, you are not just mixing them. You are reducing the particle size of your sample below the wavelength of the IR light to minimize scattering. This uniform dispersion within the KBr matrix ensures the IR beam interacts with a representative amount of your sample.

Step 1: Gathering and Preparing Your Equipment

Proper preparation prevents contamination and artifacts in your final spectrum. A clean, dry setup is non-negotiable.

Essential Tools

You will need spectroscopic-grade KBr powder, a pestle and mortar (agate is preferred to minimize contamination), a pellet press, and a die set. A small spatula and a way to handle the pellet are also necessary.

The Importance of a Dry Environment

KBr is hygroscopic, meaning it readily absorbs moisture from the air. Water has very strong, broad absorption bands in the IR spectrum (around 3400 cm⁻¹ and 1640 cm⁻¹) that can easily obscure your sample's peaks. To prevent this, always store KBr in a desiccator and consider performing the preparation under a heat lamp or in a glovebox if the lab is humid.

Cleaning the Die Set

Before starting, thoroughly clean the die anvils and collar. Wipe them with a solvent like acetone or isopropanol on a laboratory tissue to remove any residual sample or oil, then ensure they are completely dry.

Step 2: Sample Preparation and Grinding

This is the most critical step for achieving a transparent pellet and a high-quality spectrum.

Determining the Right Ratio

The ideal concentration is 0.1% to 1.0% sample in KBr. A good starting point is to use approximately 1-2 mg of your solid sample and 100-200 mg of dry KBr powder. Using too much sample will result in an opaque pellet and saturated, flat-topped peaks in your spectrum.

The Grinding Process

First, place your small amount of sample into the clean, dry mortar and grind it into the finest powder possible. Then, add about a quarter of your KBr and grind again to mix. Add the remaining KBr in portions, grinding thoroughly after each addition until the mixture is a completely homogenous, fine powder.

Step 3: Pressing the Pellet

The goal here is to fuse the KBr mixture into a solid, glass-like disc.

Loading the Die

Carefully transfer the ground powder into the die collar. Distribute it as evenly as possible over the surface of the bottom anvil to ensure the final pellet has a uniform thickness.

Applying Pressure

Place the top anvil in the collar and transfer the entire assembly to the press. Apply pressure slowly and steadily. A typical pressure is 7-10 tons for a 13 mm die, held for 1-2 minutes. This allows the KBr particles to fuse and for trapped air to escape.

Releasing Pressure and Ejecting the Pellet

Release the pressure on the press very slowly. Releasing it too quickly is the most common cause of cracked or shattered pellets. Once the pressure is fully released, carefully remove the die assembly and eject the finished pellet. A good pellet will be thin and transparent or translucent.

Understanding Common Pitfalls

If your results are poor, the pellet is almost always the cause. Understanding why it failed is key to fixing it.

Cloudy or Opaque Pellets

This is the most frequent issue. It is almost always caused by either insufficient grinding (leaving sample particles large enough to scatter light) or moisture absorbed by the KBr. Re-grind your sample more thoroughly or take greater care to keep your KBr and equipment dry.

Cracked or Brittle Pellets

A pellet that cracks or shatters upon ejection was likely compromised by trapped air. This happens when pressure is applied or released too quickly. Sometimes, applying a vacuum to the die during pressing can help remove air and moisture, leading to a better-quality pellet.

Unwanted Peaks in Your Spectrum

Seeing a broad, rolling peak around 3400 cm⁻¹ and a sharper one near 1640 cm⁻¹ means your pellet contains water. This is a sign that your KBr or sample was not dry enough. Sharp, unusual peaks could also indicate contamination from an unclean mortar or die set.

Making the Right Choice for Your Goal

The required quality of your KBr pellet depends on the purpose of your analysis.

- If your primary focus is a quick qualitative scan: A slightly cloudy pellet may be acceptable, as long as your key sample peaks are clearly distinguishable from any moisture bands.

- If your primary focus is quantitative analysis or publication-quality data: Pellet transparency is non-negotiable. Invest the extra time in meticulous drying and grinding to produce a perfectly clear disc for the most accurate and artifact-free spectrum.

Mastering this technique is a matter of practice, but focusing on dryness and thorough grinding will consistently produce high-quality results.

Summary Table:

| Step | Key Action | Critical Factor |

|---|---|---|

| 1. Preparation | Gather spectroscopic-grade KBr, clean die set, work in dry environment | Prevent moisture contamination |

| 2. Grinding | Mix 0.1-1.0% sample with KBr, grind to fine homogeneous powder | Particle size below IR wavelength |

| 3. Pressing | Load die evenly, apply 7-10 tons pressure for 1-2 minutes, release slowly | Avoid trapped air and cracking |

| 4. Troubleshooting | Address cloudy pellets (grind more), cracked pellets (release pressure slowly), water peaks (dry environment) | Achieve transparency for quality spectra |

Achieve publication-quality FTIR results with reliable sample preparation equipment from KINTEK.

Whether you're performing qualitative scans or precise quantitative analysis, the right tools make all the difference. KINTEK specializes in high-quality laboratory equipment and consumables, including pellet presses, dies, and spectroscopic-grade KBr, designed specifically for demanding laboratory environments.

Let us help you eliminate common FTIR preparation pitfalls and ensure consistent, accurate results. Contact our experts today to discuss your specific application needs and discover how KINTEK solutions can enhance your analytical workflow.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

People Also Ask

- What is the pressing process of ceramics? A Guide to Precise, High-Strength Manufacturing

- Which oil is used in hydraulic press machine? Choose the Right Fluid for Maximum Performance

- What are the critical control factors and monitoring limitations in the HPHT process? Master Stability & Efficiency

- Why is a laboratory hydraulic press required for ceramic target pre-forming? Enhance Density and Thin Film Quality

- What is the specific application of a laboratory hydraulic press in the formation of lithium-air battery air electrodes?

- What are the disadvantages of KBr pellets? Avoid Moisture & Prep Errors in FTIR Analysis

- Why do hydraulics get slow when hot? Uncover the Viscosity Breakdown and Performance Loss

- What is the function of a laboratory hydraulic press in the manufacturing of composite boards? Essential Densification