To prepare a KBr pellet, you must grind your solid sample into a fine powder, mix a very small amount (typically less than 1%) with dry, infrared-grade Potassium Bromide (KBr) powder, and then use a hydraulic press to compress the mixture in a specialized die set. The goal is to create a thin, transparent, or translucent disc through which the spectrometer's infrared beam can pass.

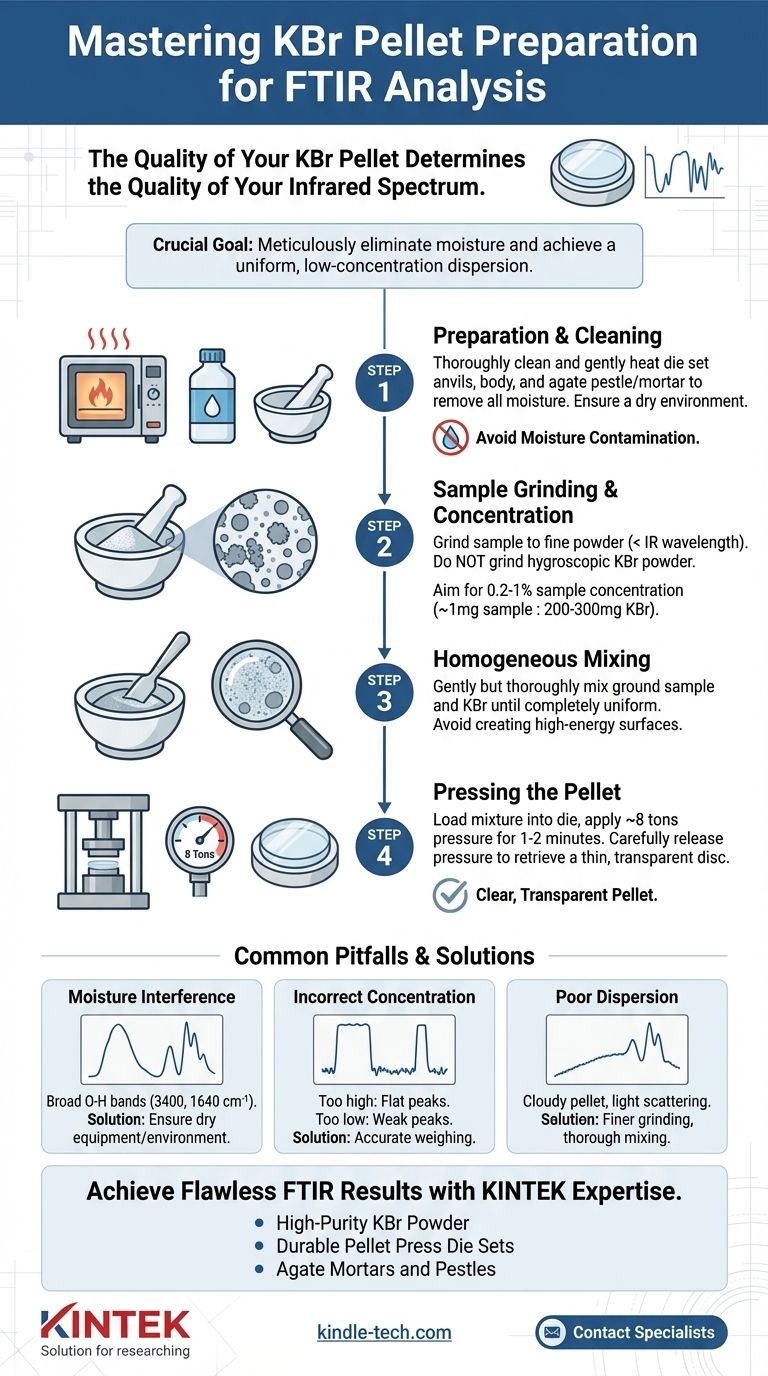

The quality of an infrared spectrum is directly determined by the quality of the KBr pellet. Success depends less on the mechanical act of pressing and more on two critical factors: meticulously eliminating moisture and achieving a uniform, low-concentration dispersion of the sample within the KBr matrix.

The Essential Toolkit and Environment

Before beginning, ensure you have the correct equipment and that your workspace minimizes potential contamination, especially from atmospheric water.

The Required Hardware

You will need a pellet press die set, which typically includes a body, a base, and two highly polished anvils. These are made of hardened metal alloys to withstand high pressure.

You also need a pestle and mortar, preferably made of agate. The non-porous, smooth surface of agate minimizes sample loss and cross-contamination compared to ceramic alternatives.

The Importance of a Dry Environment

KBr is hygroscopic, meaning it readily absorbs moisture from the air. Water has strong IR absorption bands that can easily obscure your sample's spectral features.

To combat this, store your KBr powder in a desiccator or a drying oven. If possible, perform the grinding and mixing steps in a glovebox with a dry atmosphere.

Step-by-Step Pellet Preparation

Following a systematic process is key to creating a high-quality, reproducible pellet that yields a clean spectrum.

Step 1: Meticulous Preparation and Cleaning

Begin by thoroughly cleaning all parts of the die set. Use a solvent like acetone or chloroform to remove any residual material, then wipe them completely dry with a clean tissue.

As a crucial step, gently heat the die set anvils and body, as well as the pestle and mortar, in an oven before use. This drives off any adsorbed moisture, ensuring a dry starting point.

Step 2: Sample Grinding and Concentration

The goal is to reduce your sample's particle size to be smaller than the wavelength of the IR radiation, which minimizes light scattering.

Grind a few milligrams of your solid sample in the agate mortar until it becomes a fine, flour-like powder.

Crucially, do not grind the KBr powder. Grinding KBr crystals creates fresh, high-energy surfaces that aggressively absorb atmospheric moisture. Use the KBr as supplied or by gently breaking up larger crystals if necessary.

Step 3: Homogeneous Mixing

The correct concentration is vital. Aim for a sample concentration between 0.2% and 1% in the KBr. A common ratio is approximately 1 mg of sample to 200-300 mg of KBr.

Add the pre-weighed KBr powder to the ground sample in the mortar. Mix the two components gently but thoroughly until the sample is evenly dispersed. The mixture should appear completely uniform.

Step 4: Loading and Pressing the Die

Place a small amount of the sample-KBr mixture into the die body, just enough to form a thin, even layer on the anvil face.

Assemble the die and place it in a hydraulic press. If using a vacuum die, attach the vacuum line to remove trapped air, which helps create a clearer pellet.

Apply pressure slowly, typically around 8 tons of force for a standard 13mm die. Hold the pressure for a minute or two to allow the KBr to fuse into a solid disc. Carefully release the pressure and disassemble the die to retrieve your transparent pellet.

Understanding the Trade-offs and Common Pitfalls

A poor spectrum is almost always traceable to a flaw in the pellet preparation. Understanding these issues is key to troubleshooting.

The Problem of Moisture

If your final spectrum shows broad absorption bands around 3400 cm⁻¹ (O-H stretching) and 1640 cm⁻¹ (H-O-H bending), your pellet is contaminated with water. This is the most common failure mode.

Incorrect Sample Concentration

If your sample concentration is too high, the strongest absorption bands will be "flat-topped" (total absorption), and the baseline may be noisy. If the concentration is too low, your sample's peaks will be too weak to distinguish from the background noise.

Poor Sample Dispersion

If the sample is not ground finely or mixed evenly, the resulting pellet will appear cloudy. This cloudiness is caused by light scattering from large particles, which results in a sloping baseline and distorted, poorly defined spectral peaks.

Making the Right Choice for Your Goal

Your analytical objective should guide your focus during the preparation process.

- If your primary focus is quantitative analysis: Be meticulous about weighing your sample and KBr to ensure an accurate and reproducible concentration.

- If your primary focus is qualitative identification: Your top priority is eliminating moisture contamination, as water peaks can be easily mistaken for or obscure key functional groups like alcohols or amines.

- If you are troubleshooting a noisy or sloping spectrum: The most likely cause is a cloudy pellet. Re-make the pellet, focusing on grinding the sample more finely and mixing it more thoroughly with the KBr.

Mastering this technique transforms it from a frustrating chore into a reliable tool for acquiring clean, accurate spectral data.

Summary Table:

| Key Step | Critical Factor | Common Pitfall |

|---|---|---|

| Preparation & Cleaning | Dry, heated die set and tools | Moisture contamination from humid environment |

| Sample Grinding | Particle size < IR wavelength | Cloudy pellet due to poor grinding |

| Mixing | 0.2-1% sample in KBr (1:200-300 ratio) | Incorrect concentration leading to noisy spectra |

| Pressing | 8 tons pressure for 1-2 minutes | Trapped air or uneven pressure causing cracks |

Achieve flawless FTIR results with KINTEK's expertise in laboratory sample preparation.

Struggling with cloudy pellets, water interference, or inconsistent spectra? Our team specializes in the precise equipment and consumables needed for perfect KBr pellet preparation. We provide high-purity, infrared-grade KBr powder, durable pellet press die sets, and agate mortars and pestles designed to minimize contamination and moisture absorption.

Whether you're focused on quantitative analysis or qualitative identification, KINTEK's solutions ensure your lab produces transparent, reproducible pellets every time. Let us help you eliminate common pitfalls and obtain clean, accurate spectral data.

Contact our specialists today to discuss your FTIR needs and optimize your sample preparation workflow.

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What is the pressed pellet technique? A Guide to Creating Uniform Solid Samples from Powder

- What is a punch tablet press? Precision Tableting for R&D and Small Batches

- What are the advantages of press working operation? Unlock High-Speed, Low-Cost Mass Production

- What is the difference between single punch and rotary tablet press? Choose the Right Machine for Your Lab or Production

- What are advantages of single punch tablet press machine? Maximize R&D Efficiency with Minimal Material