To prepare a pressed pellet for XRF analysis, you must first grind your sample into a very fine powder, typically smaller than 75 micrometers. This powder is then thoroughly mixed with a binding agent, loaded into a pressing die, and compressed under high pressure (usually 15-40 tons) to form a solid, stable tablet. This method is standard practice because it is fast, cost-effective, and creates the ideal sample form for accurate analysis: a dense, homogeneous disc with a perfectly flat surface.

The ultimate goal of creating a pressed pellet is not just to solidify a powder, but to eliminate analytical errors caused by inconsistent particle sizes and surface voids. A properly made pellet is the foundation of reliable and repeatable XRF data.

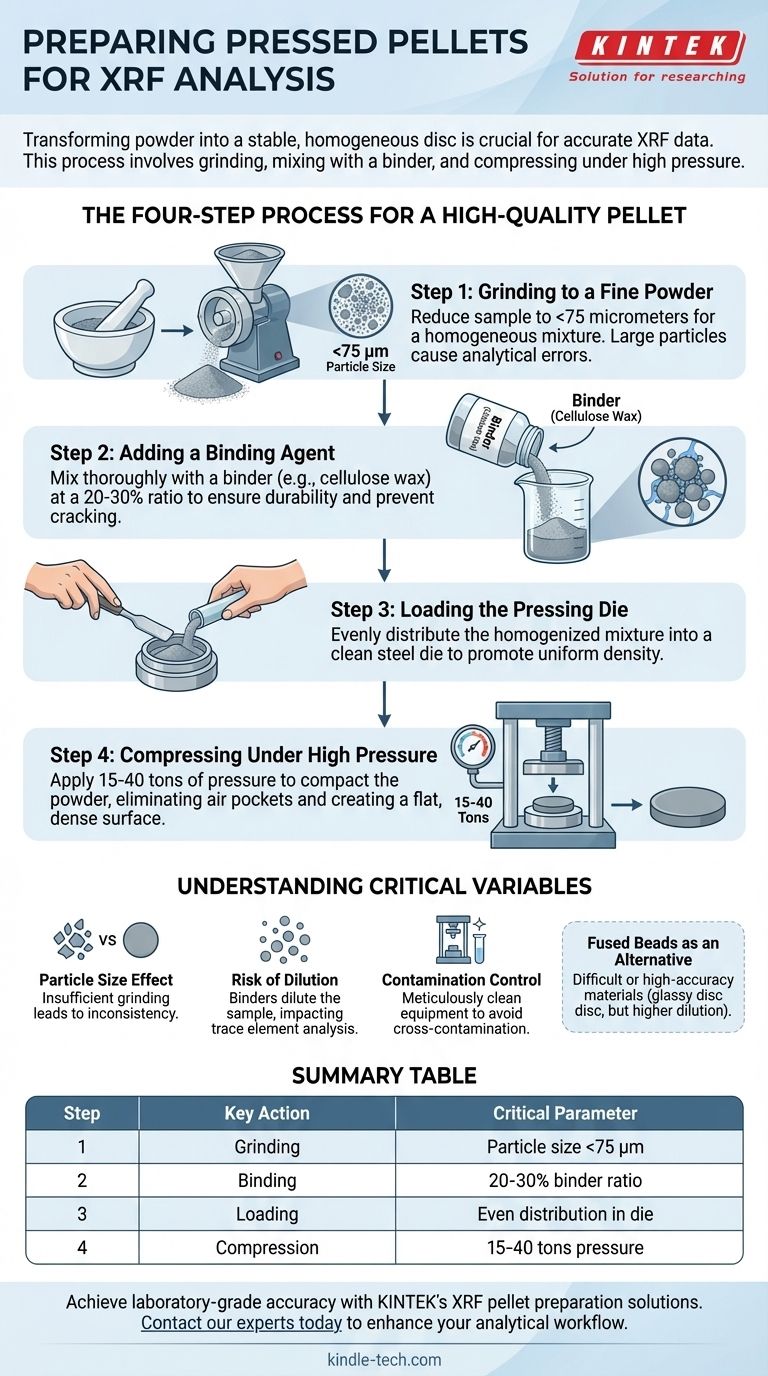

The Four-Step Process for a High-Quality Pellet

Achieving an ideal sample pellet requires a methodical approach. Each step is designed to minimize variables that can negatively impact the quality of your XRF results.

Step 1: Grinding to a Fine Powder

The first and most critical step is reducing your sample to a fine, uniform powder. The goal is to achieve a particle size of less than 75 micrometers (<75 µm).

This level of fineness is essential for creating a homogeneous sample. Large or inconsistent particles can cause the X-ray beam to scatter unpredictably, leading to significant analytical errors.

Step 2: Adding a Binding Agent

While some materials can be pressed directly, most require a binder to create a durable, crack-free pellet. This is typically a cellulose wax mixture.

A common starting point is a 20% to 30% binder-to-sample ratio. The binder fills microscopic voids and helps the sample particles adhere to one another under pressure, ensuring the final pellet is mechanically stable.

Step 3: Loading the Pressing Die

The homogenized powder and binder mixture is then poured into a pellet die. This is typically a steel cup or ring that contains the material during compression.

Ensure the die is clean to prevent cross-contamination between samples. The powder should be distributed evenly to promote uniform density in the final pellet.

Step 4: Compressing Under High Pressure

The loaded die is placed into a laboratory press. A pressure between 15 and 40 tons is applied to compact the powder into a solid tablet.

This high pressure forces out air pockets and ensures the particles are in intimate contact, creating the flat, dense surface required for accurate XRF measurements.

Understanding the Trade-offs and Critical Variables

Simply following the steps is not enough; understanding the variables and potential pitfalls is what separates acceptable results from excellent ones.

The Impact of Particle Size

If grinding is insufficient, the resulting pellet will not be truly homogeneous. This "particle size effect" is one of the most common sources of error in XRF, as larger grains can disproportionately absorb or fluoresce X-rays.

The Risk of Dilution

Using a binder is often necessary, but it also dilutes your sample. While this is less of an issue for major elements, it can be problematic for analyzing trace elements. Too much binder may push their concentration below the instrument's detection limit.

Contamination Control

Contamination can invalidate your results. Always use meticulously cleaned grinding vessels, spatulas, and pressing dies. To avoid cross-contamination, it is best practice to use dedicated equipment for vastly different sample types.

Fused Beads as an Alternative

Pressed pellets are not the only option. For materials that are very difficult to grind or for applications demanding the highest accuracy for major elements, fused beads are a common alternative. This involves mixing the sample with a lithium borate flux and melting it into a glassy disc, which guarantees perfect homogeneity but causes greater dilution.

Making the Right Choice for Your Goal

Your preparation method should align with your analytical needs. Use these guidelines to steer your approach.

- If your primary focus is rapid, routine analysis: Pressed pellets offer an unmatched balance of speed, low cost, and high-quality results for most common materials.

- If your primary focus is quantifying trace elements: Be meticulous with your binder ratio to minimize dilution and enforce strict cleaning protocols to prevent any cross-contamination.

- If your sample is cracking or mechanically unstable: Increase the binder-to-sample ratio slightly or ensure you are applying sufficient pressure within the recommended range.

- If your material is extremely hard or chemically complex: Consider the fused bead method as a more robust, albeit more involved, alternative to achieve complete homogeneity.

Ultimately, a consistent and well-documented preparation procedure is the key to generating trustworthy XRF data.

Summary Table:

| Step | Key Action | Critical Parameter |

|---|---|---|

| 1 | Grinding | Particle size <75 µm |

| 2 | Binding | 20-30% binder ratio |

| 3 | Loading | Even distribution in die |

| 4 | Compression | 15-40 tons pressure |

Achieve laboratory-grade accuracy with KINTEK's XRF pellet preparation solutions. Our specialized lab equipment and consumables are designed to help you create perfect pressed pellets every time, ensuring homogeneous samples and reliable analytical data. Whether you're processing routine samples or challenging materials, KINTEK provides the precision tools and expertise your laboratory needs. Contact our experts today to discuss your specific XRF preparation requirements and discover how we can enhance your analytical workflow.

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

People Also Ask

- How is a laboratory hydraulic press used for LLZTO pellets? Achieve 93% Density in Solid-State Battery Research

- What advantages does a hot press offer over cold pressing? Enhance Sulfide Solid-State Electrolyte Performance

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production

- How does a hydraulic hot press machine work? Unlock Precision in Material Bonding and Forming

- What role does a laboratory hydraulic press play in all-solid-state battery fabrication? Enhancing Ion Conductivity