To sterilize glassware by autoclave, you must use a cycle that employs pressurized steam at a minimum of 121°C (250°F) for at least 15-20 minutes. The core process involves properly cleaning and preparing the glassware, loading it to allow for steam penetration, and selecting the correct autoclave cycle—typically a "gravity" or "dry goods" cycle.

The key to successful sterilization is not just heat, but pressurized moist heat. An autoclave works by using steam under pressure to raise the boiling point of water, ensuring that this high-temperature moisture penetrates and destroys all microorganisms, including heat-resistant bacterial spores.

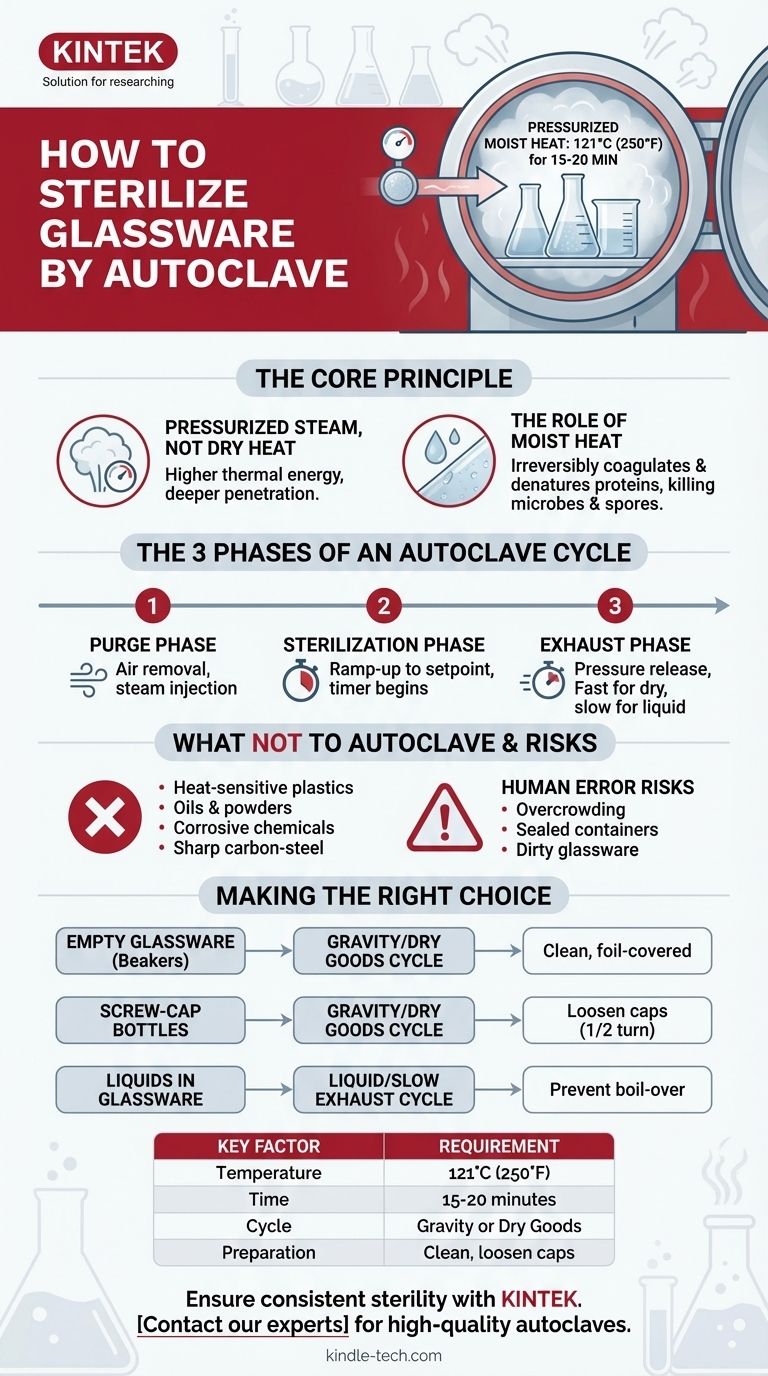

The Core Principle: How an Autoclave Achieves Sterility

Pressurized Steam, Not Just Dry Heat

An autoclave is essentially a highly controlled pressure cooker. By increasing the pressure inside its chamber, it forces water to remain liquid and turn to steam at temperatures far above its normal boiling point.

This superheated steam is the active sterilizing agent. It carries significantly more thermal energy than dry air at the same temperature, allowing for rapid and deep heat penetration.

The Role of Moist Heat

The moisture in the steam is critical. It efficiently transfers heat to any microorganisms present on the glassware.

This process, known as moist heat sterilization, kills microbes by irreversibly coagulating and denaturing their essential proteins and enzymes, a much faster and more effective method than simply baking them with dry heat.

The Three Phases of an Autoclave Cycle

Every autoclave cycle, regardless of the specific setting, proceeds through three fundamental phases. Understanding them is crucial for troubleshooting and ensuring success.

Phase 1: The Purge Phase

Once the door is sealed, the autoclave begins injecting steam into the chamber to displace the cooler, denser air. Air is a poor conductor of heat, and any trapped pockets will create "cold spots" where sterilization fails.

This phase is complete when all air has been flushed out and the chamber is filled only with pressurized steam.

Phase 2: The Sterilization (Exposure) Phase

During this phase, the autoclave's exhaust valve closes, allowing pressure and temperature to ramp up to the desired setpoint (e.g., 121°C and 15 psi).

The sterilization timer only begins once the target temperature is reached. The duration must be long enough for the superheated steam to penetrate the entire load and kill all microbial life.

Phase 3: The Exhaust Phase

Once the sterilization time is complete, the exhaust valve opens to release pressure from the chamber.

For glassware and other dry goods, a relatively fast exhaust is used, often followed by a heated drying phase to remove residual moisture. For sterilizing liquids, a very slow exhaust is critical to prevent the liquid from boiling over.

Understanding the Trade-offs and Limitations

What Not to Autoclave

An autoclave is a powerful tool, but its high heat and pressure will destroy certain materials. Never autoclave:

- Heat-sensitive plastics: Many plastics will melt or deform. Only use plastics explicitly rated as "autoclavable" (like polypropylene or polycarbonate).

- Oils and powders: Steam cannot effectively penetrate these water-insoluble substances. Dry heat sterilization is required instead.

- Corrosive or volatile chemicals: Substances like bleach or solvents can emit toxic fumes and damage the autoclave chamber.

- Sharp carbon-steel instruments: The high heat and moisture will dull the edges of non-stainless steel blades.

The Risk of Improper Preparation

The most common cause of sterilization failure is human error.

- Overcrowding the chamber prevents steam from circulating freely, creating cold spots.

- Using sealed containers creates a risk of explosion as pressure builds inside. Always loosen the caps on bottles by at least a half-turn.

- Failing to clean glassware first allows dirt and debris to shield microorganisms from the steam. Sterilization is not a substitute for cleaning.

Making the Right Choice for Your Goal

To ensure complete and safe sterilization, match your preparation and cycle selection to the specific items you are processing.

- If your primary focus is sterilizing empty glassware (beakers, flasks): Ensure items are clean, cover openings with aluminum foil, and use a standard "gravity" or "dry goods" cycle.

- If your primary focus is sterilizing screw-cap bottles or tubes: Loosen the caps significantly (a half- to full-turn) to allow pressure to equalize, preventing the glassware from shattering.

- If your primary focus is sterilizing liquids inside the glassware: Use a dedicated "liquid" or "slow exhaust" cycle to prevent the superheated liquid from boiling over violently during depressurization.

Mastering these principles ensures your glassware is a reliable foundation for your work, not a source of contamination.

Summary Table:

| Key Factor | Requirement |

|---|---|

| Sterilizing Temperature | 121°C (250°F) minimum |

| Sterilizing Time | 15-20 minutes (after reaching temperature) |

| Recommended Cycle | Gravity or Dry Goods cycle |

| Critical Preparation | Clean glassware, loosen caps, allow steam penetration |

Ensure your laboratory's glassware is consistently and reliably sterile. KINTEK specializes in providing high-quality autoclaves and lab equipment designed for precise, effective sterilization cycles. Whether you need to process glassware, liquids, or other materials, our solutions deliver the performance and safety your lab requires. Contact our experts today to find the perfect autoclave for your specific laboratory needs.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- What are the 4 principles of autoclave? Master Steam Sterilization for Your Lab

- How does the lab autoclave work? Achieve Complete Sterilization with High-Pressure Steam

- What to look for when buying an autoclave? A Guide to Selecting the Right Sterilization Technology

- What is the temperature effective for sterilization using autoclave? Achieve Sterile Conditions for Your Lab

- What are the requirements for an autoclave machine? Achieve Sterile Confidence for Your Lab