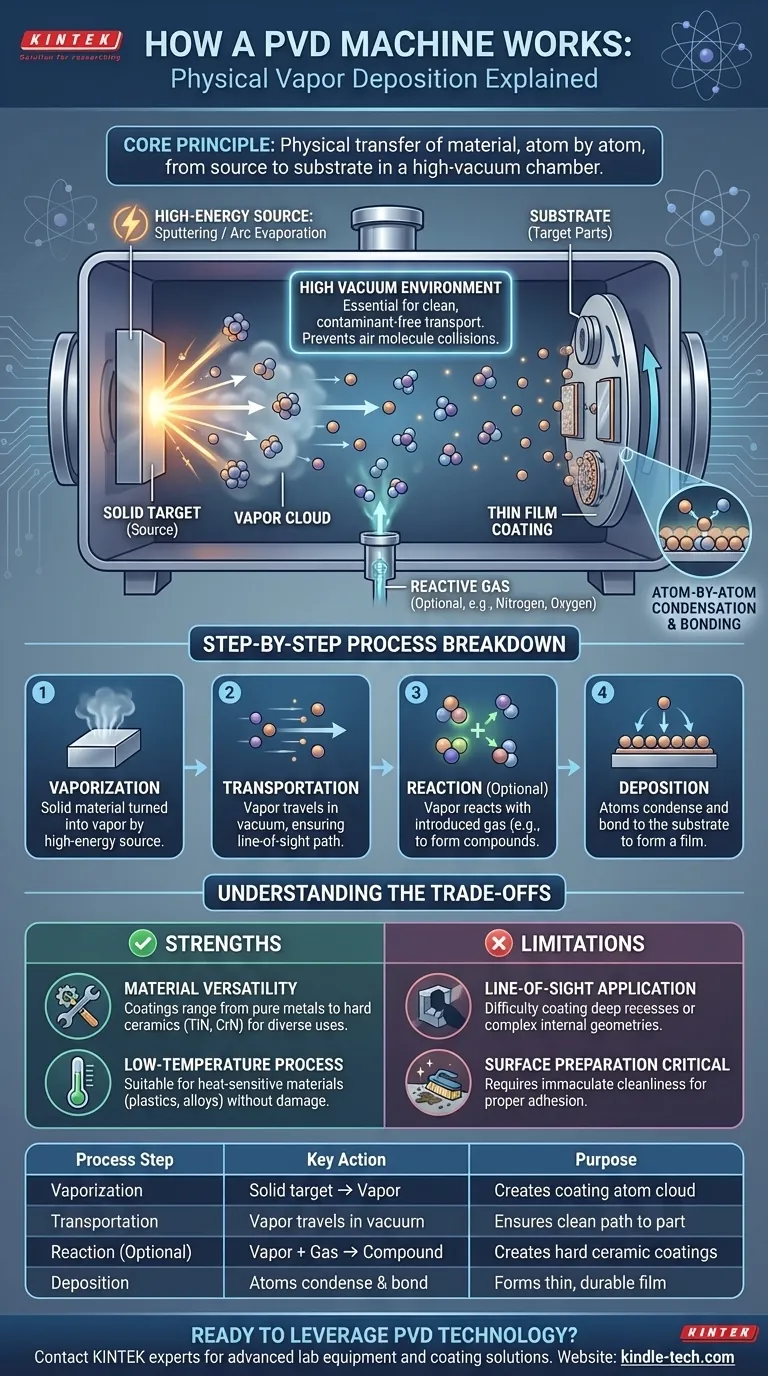

At its core, a Physical Vapor Deposition (PVD) machine works by taking a solid coating material, turning it into a vapor inside a high-vacuum chamber, and then allowing that vapor to condense onto the surface of a part, forming a thin, durable film. This entire process is a physical transfer of material, atom by atom, from a source to a substrate without a primary chemical reaction.

While the term "Physical Vapor Deposition" sounds complex, the underlying principle is simple and highly controlled. It's a line-of-sight process that physically moves material from a source to a target part inside a vacuum, offering exceptional control over the final coating's properties.

The Fundamental Principle: A Journey in a Vacuum

To truly understand how a PVD machine functions, you must think of it as a controlled environment for transporting atoms. Every stage is designed for precision.

The Source: From Solid to Vapor

The process begins with the "target," which is a block of the pure material you want to use for the coating (e.g., titanium, chromium, gold).

A high-energy source inside the vacuum chamber is directed at this target. This energy, often from a plasma (in a process called sputtering) or an electric arc (arc evaporation), is powerful enough to knock individual atoms or small clusters of atoms off the target, turning the solid material into a vapor.

The Chamber: The Importance of the Vacuum

This entire process happens inside a sealed chamber where virtually all the air has been pumped out to create a high vacuum.

This vacuum is not an afterthought; it is critical. Without it, the vaporized coating atoms would collide with air molecules (like oxygen and nitrogen), contaminating the coating and preventing them from reaching the part effectively. The vacuum ensures a clear, unobstructed path.

The Destination: Condensation and Film Growth

The vaporized atoms travel in a straight line from the source until they strike a surface. The parts to be coated are strategically placed within the chamber to intercept this vapor cloud.

When the vapor atoms hit the cooler surface of the part (the "substrate"), they rapidly cool, condense, and bond to the surface. This happens layer by layer, atom by atom, creating an extremely thin, dense, and well-adhered film.

A Step-by-Step Breakdown of the Process

While the principle is straightforward, the operational process can be broken down into four distinct steps.

Step 1: Vaporization

The cycle begins by generating a vapor from the solid source material. The PVD machine uses an energy source to bombard the target, dislodging atoms and creating a cloud of material within the chamber.

Step 2: Transportation

The vaporized atoms travel from the target toward the substrate parts. Because this occurs in a vacuum, the path is direct and predictable, a key characteristic known as line-of-sight deposition.

Step 3: Reaction (Optional but Crucial)

For basic metallic coatings, this step is skipped. However, for many high-performance applications, a specific reactive gas (like nitrogen, oxygen, or methane) is precisely introduced into the chamber.

The vaporized metal atoms react with this gas during their flight to form new compounds. This is how hard ceramic coatings like Titanium Nitride (TiN), Titanium Carbide (TiC), or Chromium Oxide (Cr₂O₃) are created. This "reactive PVD" process is what gives coatings their specific properties like extreme hardness or color.

Step 4: Deposition

This is the final step where the coating material—either pure metal vapor or the newly formed compound—condenses onto the substrate. The machine controls variables like temperature and pressure to ensure the film grows with the desired structure, density, and adhesion.

Understanding the Trade-offs

PVD technology is powerful, but its physical nature creates specific strengths and limitations that are important to understand.

Strength: Material Versatility

PVD can deposit a vast range of materials, including pure metals, alloys, and very hard ceramic compounds. This makes it suitable for everything from decorative finishes to high-performance cutting tools.

Strength: Low-Temperature Process

Compared to other methods like Chemical Vapor Deposition (CVD), PVD is a "cold" process. This allows for coating heat-sensitive materials, such as plastics or certain metal alloys, without damaging them.

Limitation: Line-of-Sight Application

Because the vapor travels in a straight line, PVD is excellent at coating surfaces it can "see." However, it struggles to coat deep recesses, internal bores, or complex, shadowed geometries without sophisticated fixtures that rotate the part on multiple axes.

Limitation: Surface Preparation is Critical

The quality of a PVD coating is heavily dependent on the cleanliness and preparation of the substrate. The surface must be immaculately clean for the atomic-level bond to form correctly. Any oil, dust, or oxide layer will result in poor adhesion.

Making the Right Choice for Your Goal

Understanding the PVD process empowers you to select it for the right reasons and to design parts that are optimized for coating.

- If your primary focus is extreme hardness and wear resistance: PVD is the definitive choice for applying ceramic coatings like TiN, AlTiN, or CrN to cutting tools, dies, and wear components.

- If your primary focus is a durable, high-end decorative finish: PVD provides brilliant, long-lasting metallic colors (gold, black, bronze) on watches, faucets, and consumer electronics that are far superior to traditional plating.

- If your primary focus is biocompatibility: PVD is used to apply inert coatings like Titanium or Hydroxyapatite to medical implants, ensuring they are not rejected by the body.

- If your primary focus is coating complex internal channels: You should consider that PVD has limitations and may require specialized setups or an alternative process like CVD or plating.

By understanding how a PVD machine physically transfers material atom by atom, you can better leverage its unique capabilities for your specific application.

Summary Table:

| Process Step | Key Action | Purpose |

|---|---|---|

| Vaporization | Solid target material is vaporized (e.g., via sputtering). | Creates a cloud of coating atoms. |

| Transportation | Vaporized atoms travel in a straight line through a vacuum. | Ensures a clean, contaminant-free path to the part. |

| Reaction (Optional) | Vapor reacts with a gas (e.g., Nitrogen) to form a compound. | Creates hard ceramic coatings like Titanium Nitride (TiN). |

| Deposition | Atoms condense and bond to the substrate surface. | Forms a thin, dense, and highly adherent film. |

Ready to leverage PVD technology for your application?

KINTEK specializes in advanced lab equipment and consumables for coating development and production. Whether you are working on cutting tools, medical implants, or decorative finishes, our expertise can help you achieve superior, durable coatings.

Contact our experts today to discuss how our PVD solutions can enhance your product's performance and durability.

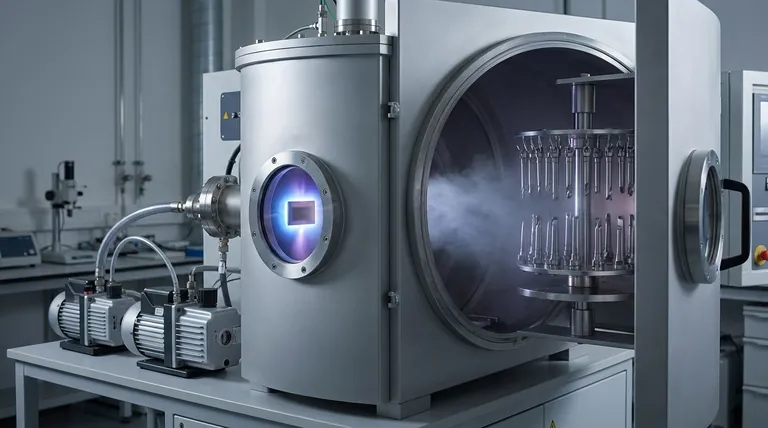

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process

- How does hot pressing work? Achieve Maximum Density for Advanced Materials

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding