At its core, a tube furnace works by heating samples indirectly within a contained tube. Rather than exposing the sample to heating elements directly, the furnace heats the exterior of a ceramic or quartz tube. This tube then radiates heat inward, uniformly raising the temperature of the sample inside while isolating it from the outside environment.

The crucial insight is that a tube furnace isn't just a heater; it's a highly controlled micro-environment. The tube itself acts as a sealed chamber, enabling precise control over the atmosphere (gas or vacuum) surrounding the sample—a capability essential for advanced materials processing.

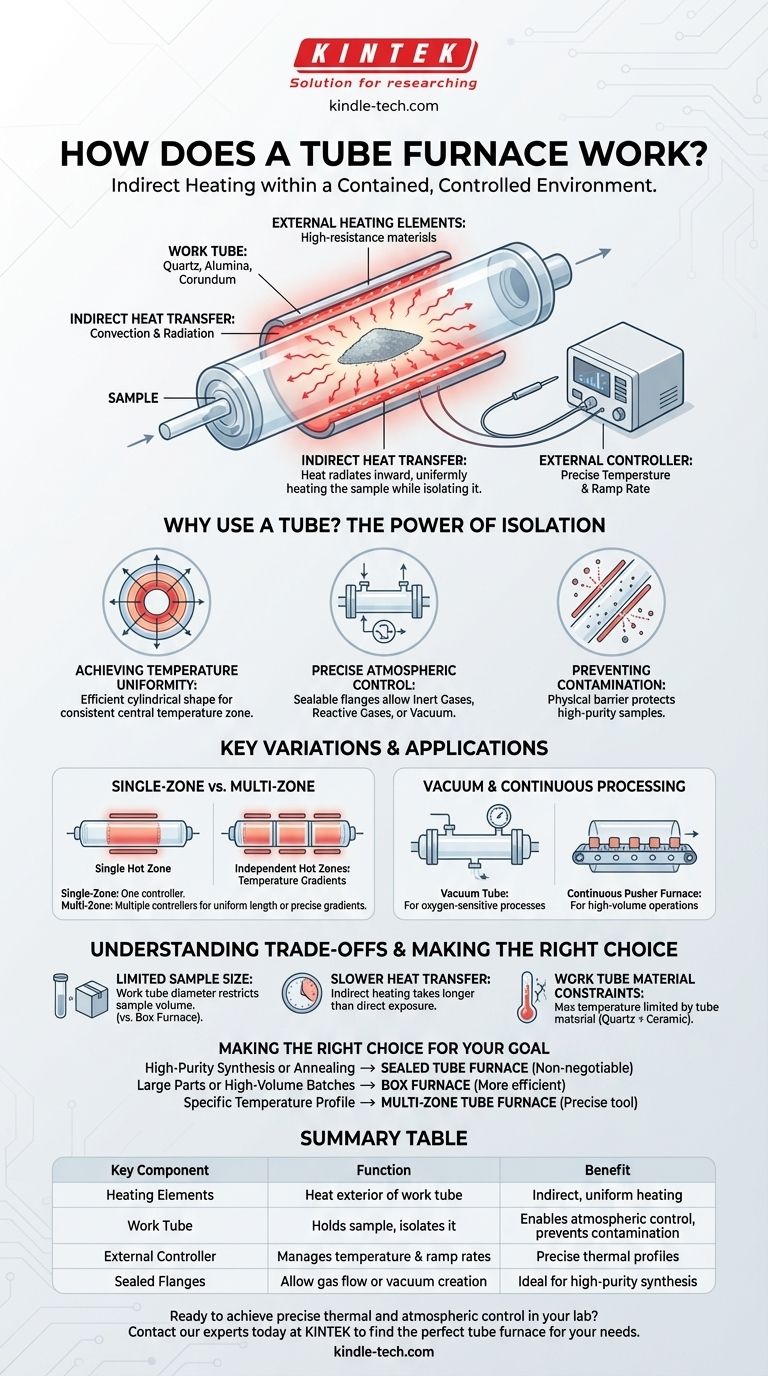

The Core Operating Principle: Indirect Heating

The mechanics of a tube furnace are straightforward, centered on isolating the sample to achieve environmental control.

The Heating Elements

The process begins with external heating elements, typically made of high-resistance materials, that surround a central chamber but do not enter it. When electricity is passed through them, they heat up significantly.

The Work Tube

A work tube, made from materials like quartz, alumina, or corundum, is placed through the center of the heated chamber. This tube serves as the container for the sample material.

Indirect Heat Transfer

The heating elements heat the outside of the work tube. This heat is then transferred through the tube's wall to the sample inside via convection and radiation. This gradual, indirect heating is key to achieving temperature stability.

The Controller

The user sets a target temperature and ramp rate on an external controller. This device uses a thermocouple to measure the furnace temperature and adjusts power to the heating elements to precisely follow the desired profile.

Why Use a Tube? The Power of Isolation

The cylindrical tube is what distinguishes this furnace. Its geometry and the ability to seal it provide two fundamental advantages over a standard box furnace.

Achieving Temperature Uniformity

A cylinder is an inherently efficient shape for uniform heating. Heat radiates inward from all sides toward the central axis, creating a very consistent temperature zone in the middle of the tube.

Precise Atmospheric Control

Because the sample is inside a sealed tube, you have complete control over its gaseous environment. Sealing flanges can be attached to the ends of the tube, allowing you to:

- Introduce inert gases (like argon or nitrogen) to prevent oxidation.

- Pass reactive gases through the tube for specific chemical processes.

- Pull a vacuum to remove all atmospheric gases for high-purity applications.

Preventing Contamination

The work tube acts as a physical barrier, protecting the sample from any potential contaminants shed by the heating elements or insulation. This is critical for creating high-purity materials.

Key Variations and Their Applications

Not all tube furnaces are the same. Their design is tailored to specific scientific and industrial tasks.

Single-Zone vs. Multi-Zone Furnaces

A single-zone furnace has one set of heating elements and one controller, creating a single hot zone in the center. A multi-zone furnace has several independent sets of heating elements and controllers along its length. This allows for a much longer uniform temperature zone or the creation of precise temperature gradients.

Vacuum Tube Furnaces

This is a specific configuration where the tube is sealed with vacuum-tight flanges. It's a type of "hot wall" furnace because the tube itself gets hot while under vacuum. These are essential for processes that are highly sensitive to oxygen or other atmospheric components.

Continuous vs. Batch Processing

Most lab tube furnaces are used for batch processing, where a sample is loaded, heated, and then removed. Some industrial versions, like a pusher furnace, allow for continuous operation by pushing a train of sample-filled "boats" through the tube.

Understanding the Trade-offs

While powerful, tube furnaces are not the solution for every heating application.

Limited Sample Size

The diameter of the work tube inherently restricts the size and volume of the sample you can process at one time. A box furnace can accommodate much larger or more numerous samples.

Slower Heat Transfer

Because the heat must travel through the work tube to reach the sample, the overall heating process can be slower compared to furnaces where the sample is exposed directly to the heating elements.

Work Tube Material Constraints

The maximum operating temperature of the furnace is often limited by the material of the work tube. Quartz is common but has a lower temperature limit than ceramic tubes like alumina, which can withstand much higher heat but may be more brittle.

Making the Right Choice for Your Goal

Selecting the right heating equipment depends entirely on your primary objective.

- If your primary focus is high-purity synthesis or annealing: The superior atmospheric control of a sealed tube furnace is non-negotiable.

- If your primary focus is processing large parts or high-volume batches: A box furnace offers far more capacity and may be more efficient.

- If your primary focus is creating a specific temperature profile along your sample: A multi-zone tube furnace is the only tool designed for this precise task.

Ultimately, a tube furnace is the premier choice when the precision of the thermal and atmospheric environment is more important than sample size or processing speed.

Summary Table:

| Key Component | Function | Benefit |

|---|---|---|

| Heating Elements | Heat the exterior of the work tube | Indirect, uniform heating |

| Work Tube | Holds the sample and isolates it | Enables atmospheric control (gas/vacuum) and prevents contamination |

| External Controller | Manages temperature and ramp rates | Precise thermal profiles for consistent results |

| Sealed Flanges | Allow gas flow or vacuum creation | Ideal for high-purity synthesis and annealing |

Ready to achieve precise thermal and atmospheric control in your lab?

At KINTEK, we specialize in high-performance tube furnaces designed for advanced materials processing. Whether you need single-zone consistency or multi-zone gradients, our equipment ensures the precision and reliability your research demands.

Contact our experts today to find the perfect tube furnace for your laboratory needs and elevate your materials synthesis, annealing, or heat treatment processes.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- What are the advantages of a tube furnace? Achieve Superior Thermal Control and Purity

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- What are the hazards of a tube furnace? Beyond the Obvious Burn Risks