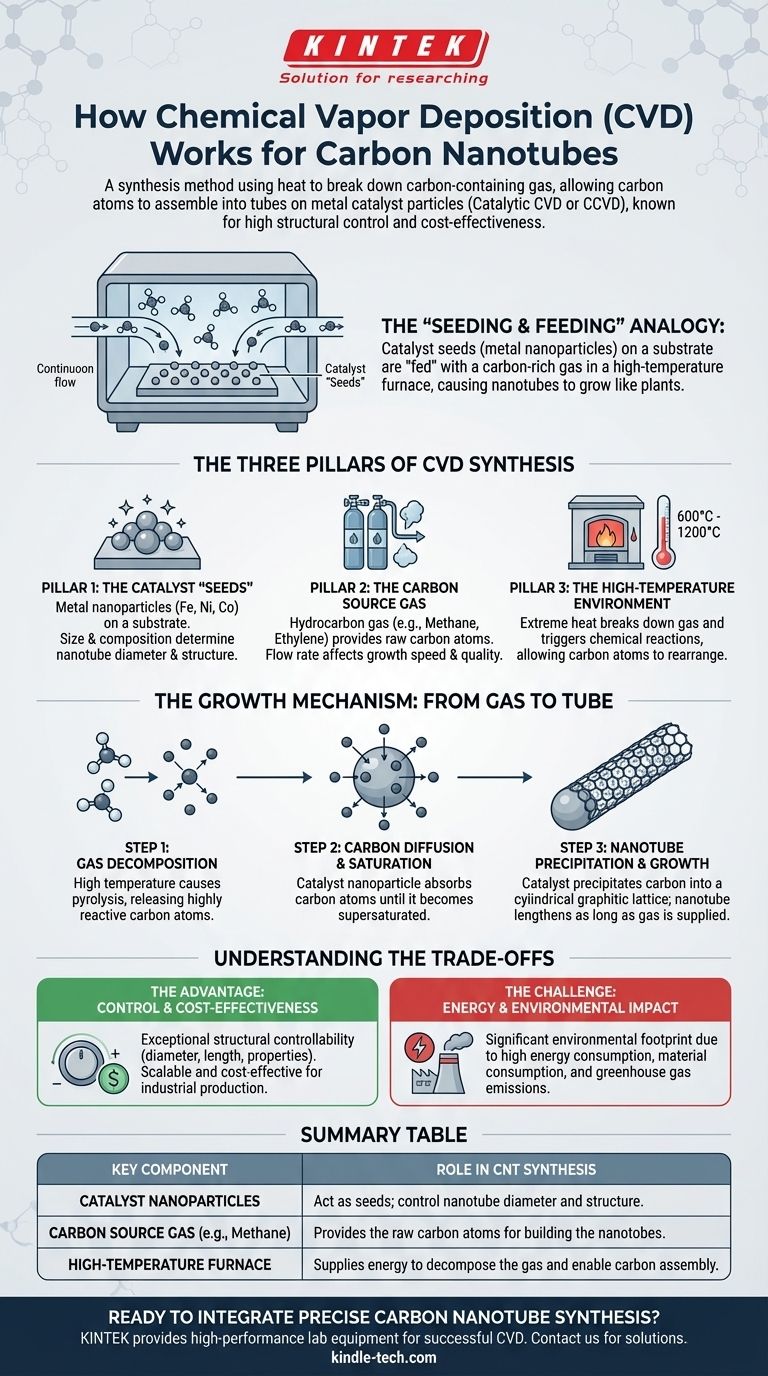

At its core, chemical vapor deposition (CVD) for carbon nanotubes is a synthesis method that uses heat to break down a carbon-containing gas, allowing carbon atoms to assemble into tube-like structures on the surface of tiny metal catalyst particles. This process, often called catalytic CVD (CCVD), is the most common and cost-effective way to produce carbon nanotubes with a high degree of structural control.

The simplest way to understand CVD for nanotubes is to think of it as "seeding" a surface with catalyst nanoparticles and then "feeding" those seeds with a carbon-rich gas in a high-temperature furnace. The nanotubes then grow from these catalyst seeds, much like a plant grows from the ground.

The Three Pillars of CVD Synthesis

To understand how carbon nanotubes (CNTs) are grown, you must first understand the three essential components required for the process to work. Each plays a distinct and critical role.

Pillar 1: The Catalyst "Seeds"

The entire process begins with a catalyst. These are typically nanoparticles of metals like iron, nickel, or cobalt.

These particles are deposited onto a stable, heat-resistant base material called a substrate. The size and composition of these catalyst particles are critical, as they directly influence the diameter and structure of the nanotubes that will grow from them.

Pillar 2: The Carbon Source Gas

A hydrocarbon gas, such as methane, ethylene, or acetylene, is continuously fed into the reaction chamber.

This gas acts as the raw material—the source of the carbon atoms that will eventually form the nanotube. The choice of gas and its flow rate affect the growth speed and quality of the final product.

Pillar 3: The High-Temperature Environment

The substrate and catalyst are placed inside a furnace and heated to very high temperatures, typically between 600°C and 1200°C.

This extreme heat provides the necessary energy to trigger the chemical reactions. It breaks down the carbon source gas and enables the carbon atoms to rearrange themselves on the catalyst surface.

The Growth Mechanism: From Gas to Tube

Once the three pillars are in place, a precise sequence of events unfolds at the nanoscale to form the carbon nanotube.

Step 1: Gas Decomposition

The high temperature in the furnace causes the hydrocarbon gas molecules to break apart, a process called pyrolysis. This releases highly reactive, individual carbon atoms.

Step 2: Carbon Diffusion and Saturation

These free carbon atoms are then absorbed by the metal catalyst nanoparticles. The atoms diffuse through the bulk of the metal particle or across its surface.

The catalyst particle continues to absorb carbon until it becomes supersaturated—it cannot hold any more.

Step 3: Nanotube Precipitation and Growth

Once saturated, the catalyst precipitates the carbon atoms out in a stable, organized structure. This structure is the cylindrical, graphitic lattice of a carbon nanotube.

The nanotube continues to lengthen as long as there is a supply of carbon gas and the catalyst remains active. The process stops when the reaction conditions are changed or the catalyst becomes deactivated.

Understanding the Trade-offs

While CVD is the dominant method for CNT synthesis, it is essential to understand its advantages and inherent challenges.

The Advantage: Control and Cost-Effectiveness

CVD is the mainstream synthesis method because it offers exceptional structural controllability. By carefully tuning the catalyst, temperature, and gas mixture, researchers can influence the diameter, length, and even the electronic properties of the nanotubes.

Furthermore, it is a highly scalable and cost-effective process, making it suitable for the industrial production required for commercial applications.

The Challenge: Energy and Environmental Impact

The primary downside of CVD lies in its environmental footprint. The synthesis process itself is the main source of potential ecotoxicity.

This is driven by high energy consumption to maintain furnace temperatures, the consumption of precursor materials (gases), and the emission of greenhouse gases as byproducts of the reaction.

Making the Right Choice for Your Goal

Understanding the fundamentals of CVD allows you to align the process with your specific objectives.

- If your primary focus is research and precise structural control: Concentrate on engineering the catalyst particle size and optimizing process parameters like temperature and gas flow rates.

- If your primary focus is cost-effective, large-scale production: Recognize that CVD is the industry standard, but prioritize optimizing for energy efficiency and minimizing waste to improve your bottom line.

- If your primary focus is minimizing environmental impact: Investigate emerging low-temperature CVD techniques, explore alternative "green" catalysts, and implement robust systems for energy recovery and emission control.

Ultimately, chemical vapor deposition is a powerful and versatile tool for creating nanomaterials, but mastering it means balancing its exceptional control with its significant resource demands.

Summary Table:

| Key Component | Role in CNT Synthesis |

|---|---|

| Catalyst Nanoparticles | Act as seeds; control nanotube diameter and structure. |

| Carbon Source Gas (e.g., Methane) | Provides the raw carbon atoms for building the nanotubes. |

| High-Temperature Furnace | Supplies energy to decompose the gas and enable carbon assembly. |

Ready to integrate precise carbon nanotube synthesis into your research or production line?

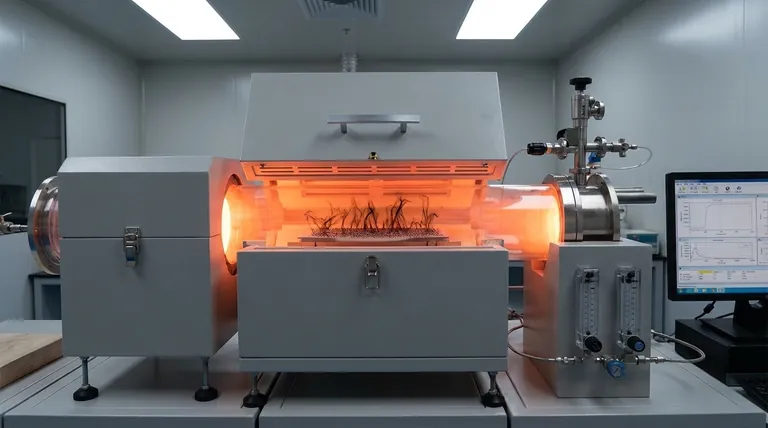

The controlled growth of CNTs via CVD requires reliable, high-performance lab equipment. KINTEK specializes in providing the furnaces, gas handling systems, and consumables essential for successful catalytic chemical vapor deposition.

Contact us today to discuss how our solutions can help you achieve superior control over your nanotube synthesis, whether for advanced research or scalable production.

Get in touch with our experts →

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques