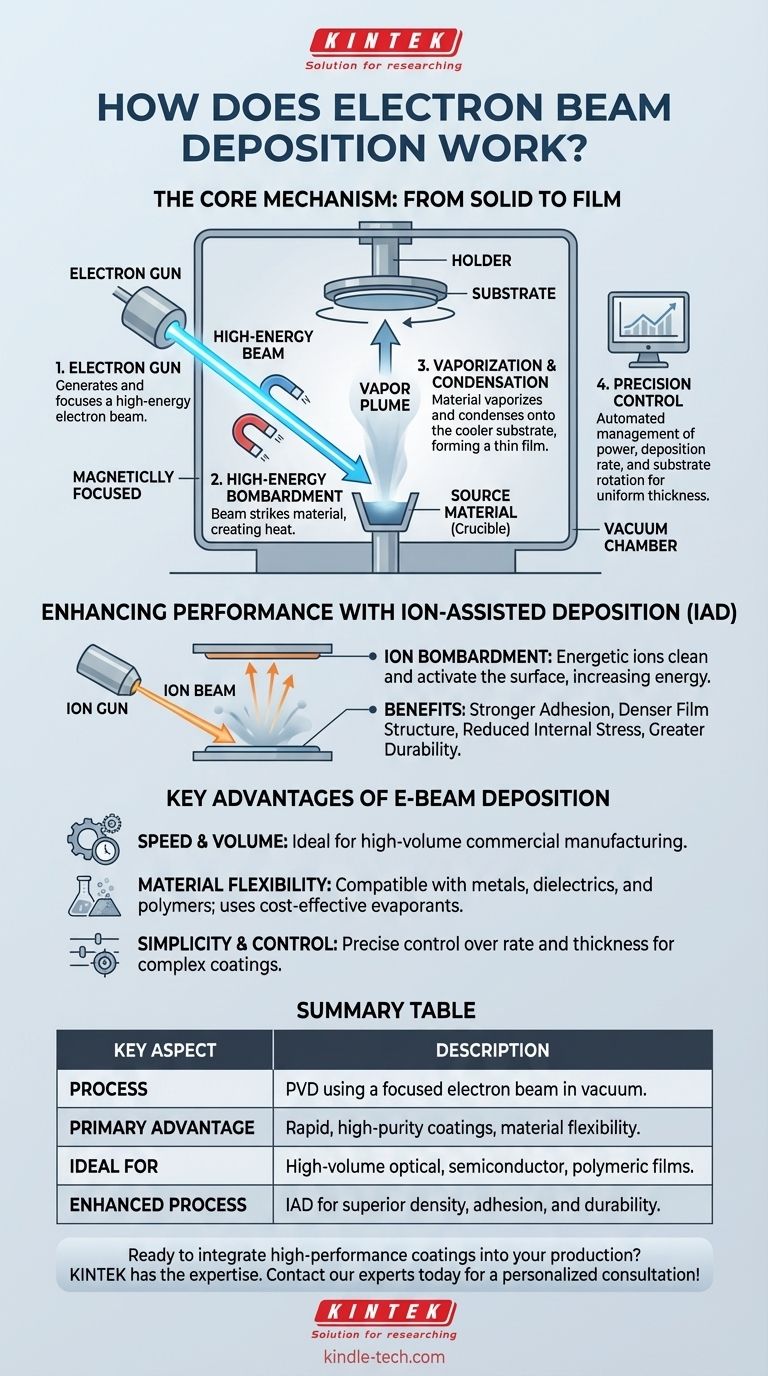

At its core, electron beam deposition is a physical vapor deposition (PVD) technique where an intense, focused beam of electrons heats a source material in a high-vacuum chamber. This energy causes the material to vaporize, and the resulting vapor travels through the vacuum to condense onto a cooler substrate, forming a highly pure and uniform thin film. This process is governed by precision computer control over factors like vacuum level, heating, and substrate rotation to achieve exact coating thicknesses.

The true value of electron beam deposition lies in its combination of speed, material flexibility, and precision. It excels at rapidly creating high-quality optical and polymeric coatings, offering a distinct advantage in high-volume commercial applications where both performance and cost-efficiency are critical.

The Core Mechanism: From Solid to Film

To understand electron beam deposition, it's best to break it down into a sequence of distinct physical events that occur within the vacuum chamber.

The Electron Gun

The process begins with an electron gun, which generates a high-energy beam of electrons. This beam is then magnetically guided and focused with extreme precision onto a small crucible containing the source material you wish to deposit.

High-Energy Bombardment

Inside the high-vacuum environment, the focused electron beam strikes the source material—often in granular or powder form. The kinetic energy of the electrons is instantly converted into thermal energy, rapidly heating the material to its vaporization point.

Vaporization and Condensation

As the source material vaporizes, its atoms or molecules travel in a straight line through the vacuum. They eventually strike the cooler substrate (such as an optical lens or silicon wafer) that is strategically placed above the source. Upon contact, the vapor condenses back into a solid state, building up layer by layer to form a thin film.

Precision Control

The entire process is tightly controlled. Computers monitor and adjust the electron beam's power to manage the deposition rate, while the substrate is often rotated to ensure the final film has a uniform, pre-specified thickness across its entire surface.

Enhancing Performance with Ion-Assisted Deposition

For applications demanding superior film quality, the standard E-beam process can be augmented with an ion beam, a technique known as Ion-Assisted Deposition (IAD).

The Role of the Ion Beam

In an IAD setup, a separate ion gun bombards the substrate surface with energetic ions, typically before and during the deposition process.

Surface Activation and Cleaning

This ion bombardment serves a critical purpose: it cleans the substrate by sputtering away contaminants and increases the surface energy. This creates a highly activated surface that is much more receptive to the depositing material.

Denser, More Robust Films

The result is a significant improvement in film quality. The added energy from the ions leads to stronger adhesion, a denser film structure, and reduced internal stress. These coatings are more robust and durable than those produced by E-beam alone.

Understanding the Key Advantages

Electron beam deposition is not the only PVD method, but it holds several advantages that make it the preferred choice for specific applications, especially when compared to techniques like magnetron sputtering.

Advantage: Speed and Volume

E-beam deposition processes more rapidly in batch scenarios. This efficiency makes it an ideal solution for high-volume commercial manufacturing where throughput is a primary concern.

Advantage: Material Flexibility

The technique is compatible with a vast array of materials, including metals, dielectrics, and even polymers. The source materials, or evaporants, are often less expensive than the specialized targets required for magnetron sputtering.

Advantage: Simplicity and Control

While the physics is complex, the operational principle is relatively straightforward and flexible. It allows for precise control over the deposition rate and resulting film thickness, which is crucial for creating complex optical interference coatings.

Making the Right Choice for Your Goal

Selecting the right deposition technique depends entirely on your project's specific requirements for performance, material, and production volume.

- If your primary focus is high-volume optical coating manufacturing: E-beam deposition is a leading choice due to its rapid batch processing and material versatility.

- If your primary focus is achieving maximum film adhesion and durability: You should specify an E-beam process enhanced with Ion-Assisted Deposition (IAD).

- If your primary focus is cost-effective sourcing for a wide range of materials: E-beam's ability to use less expensive evaporants provides a significant economic advantage over target-based methods.

Ultimately, electron beam deposition offers a powerful and versatile tool for engineering precise, high-performance thin films at scale.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Physical Vapor Deposition (PVD) using a focused electron beam to vaporize a source material in a vacuum. |

| Primary Advantage | Rapid deposition of high-purity coatings with excellent material flexibility. |

| Ideal For | High-volume manufacturing of optical coatings, semiconductor layers, and polymeric films. |

| Enhanced Process | Ion-Assisted Deposition (IAD) for superior film density, adhesion, and durability. |

Ready to integrate high-performance coatings into your production?

Electron beam deposition is a powerful solution for creating precise, high-purity thin films at scale. Whether your project requires rapid batch processing for optical components or the enhanced durability of Ion-Assisted Deposition, KINTEK has the expertise and equipment to meet your laboratory's specific needs.

Let's discuss how our lab equipment and consumables can optimize your thin film processes. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What does a thermal evaporator do? Achieve High-Purity Thin Film Deposition

- What is the electron beam evaporation process? Achieve High-Purity Thin Film Deposition

- What is the evaporation method of deposition? A Guide to High-Speed Thin Film Coating

- What factors affect evaporation and condensation? Master the Science of Water's Phase Changes

- What is the process of e-beam coating? Achieve High-Purity, Precise Thin Films for Your Lab

- What are the advantages of e-beam deposition? Achieve High-Purity, High-Melting-Point Thin Films

- What is the deposition of thin films? A Guide to Coating Technology for Modern Devices

- What is film thickness uniformity? Achieve Consistent Performance and Higher Yield