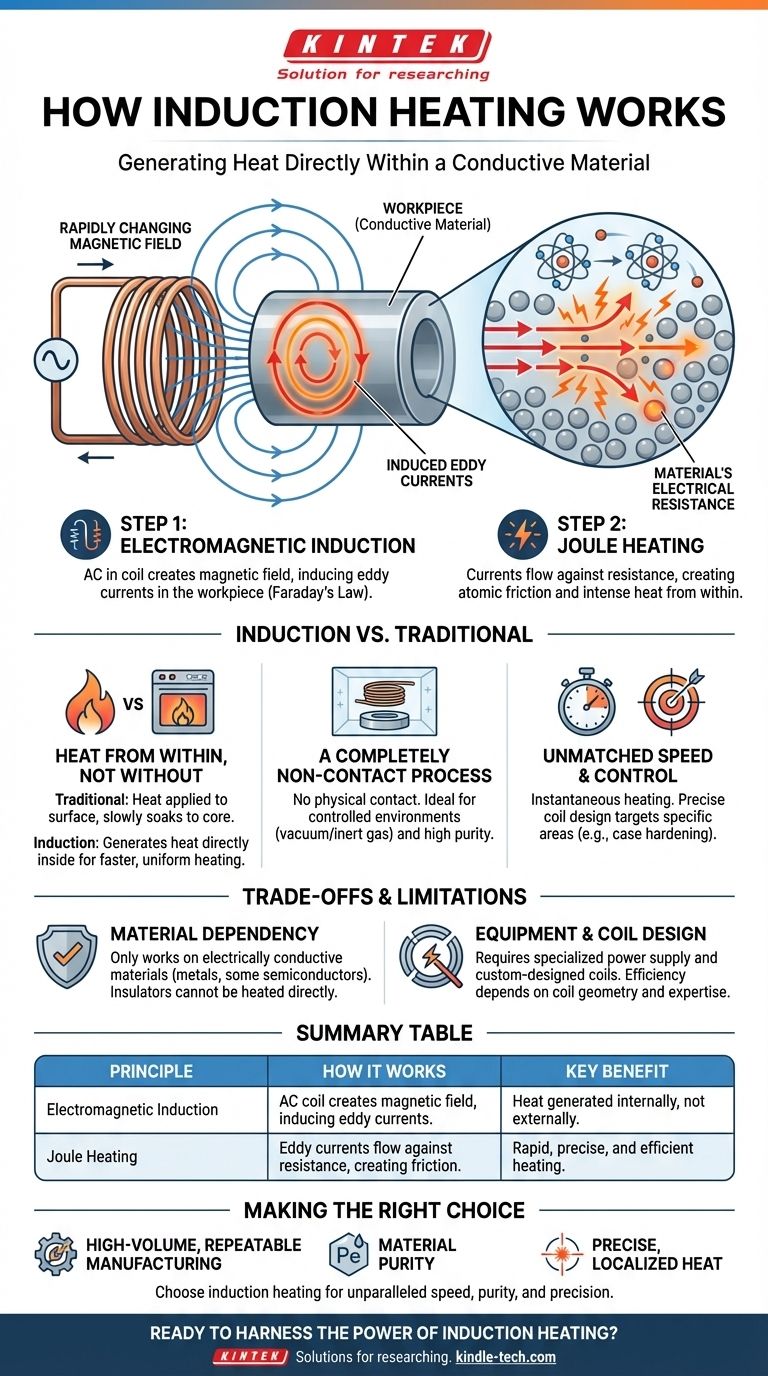

At its core, induction heating generates heat directly within a conductive material itself. It uses a powerful, rapidly changing magnetic field to create internal electrical currents within the part. As these currents flow against the material's natural electrical resistance, intense and precise heat is produced without any physical contact from an external source.

Induction heating is not about applying external heat; it's about using electromagnetic principles to turn the material into its own heat source. This non-contact method provides unparalleled speed, precision, and efficiency by generating heat internally through induced electrical currents.

The Two Core Principles of Induction Heating

The process works through a direct, two-step physical principle. Understanding both steps is key to grasping why it is so effective.

Step 1: Electromagnetic Induction

An alternating current (AC) is passed through a specially designed induction coil (typically made of copper).

According to Faraday's Law of Induction, this alternating current in the coil generates a powerful and rapidly changing magnetic field around it.

When an electrically conductive workpiece, such as a piece of metal, is placed within this magnetic field, the field induces circulating electrical currents inside the workpiece. These are known as eddy currents.

Step 2: Joule Heating

The induced eddy currents are not flowing through a perfect conductor. Every material has some degree of electrical resistivity.

As the eddy currents flow against the material's resistance, friction is created on an atomic level. This friction manifests as intense heat. This effect is known as Joule heating.

The heat is generated inside the material and then spreads throughout the part via thermal conduction. The amount of heat is a function of the current's strength and the material's resistance.

Why This Method is Different

Induction heating's unique mechanism gives it significant advantages over traditional methods like flame, resistance, or furnace heating.

Heat From Within, Not Without

In a conventional oven or with a flame, heat is applied to the surface of a part and must slowly soak into the core.

Induction heating is fundamentally different. It generates heat directly inside the material, leading to much faster and more uniform heating cycles. This also prevents surface contamination, as there are no combustion byproducts.

A Completely Non-Contact Process

The induction coil never touches the workpiece. The energy is transferred entirely through the magnetic field.

This allows for heating in controlled environments, such as a vacuum or inert gas, which is critical for producing high-purity metals and alloys.

Unmatched Speed and Control

Because the heating is direct and instantaneous, the process is extremely fast.

Furthermore, the magnetic field can be precisely controlled by the shape of the induction coil. This allows heat to be targeted to very specific areas of a part, enabling processes like case hardening a gear tooth while leaving the core ductile.

Understanding the Trade-offs and Limitations

While powerful, induction heating is not a universal solution. Its effectiveness is dependent on specific conditions and requirements.

Material Dependency

The most significant limitation is that the process only works on electrically conductive materials.

Metals and some semiconductors (like graphite or silicon carbide) heat very well. However, electrical insulators like most ceramics, plastics, glass, or wood cannot be heated directly by induction.

Equipment and Coil Design

Induction heating systems require a specialized high-frequency power supply and a custom-designed induction coil. The initial capital investment can be higher than for a simple torch or oven.

The efficiency and heat pattern are highly dependent on the coil's geometry and its proximity to the workpiece. Designing an effective coil for a complex part requires significant expertise.

Making the Right Choice for Your Goal

Induction heating is a specialized tool. You should choose it when its unique benefits align with your primary objective.

- If your primary focus is high-volume, repeatable manufacturing: Induction is ideal due to its incredible speed, consistency, and potential for automation in processes like hardening, tempering, and brazing.

- If your primary focus is material purity: The non-contact nature of induction heating makes it the superior choice for melting metals in a vacuum or controlled atmosphere, preventing any contamination.

- If your primary focus is precise, localized heat: Induction's ability to selectively heat a small zone of a larger part without affecting the surrounding areas is unmatched by almost any other method.

Understanding this fundamental principle of internal heating is the key to unlocking its power for your specific application.

Summary Table:

| Principle | How It Works | Key Benefit |

|---|---|---|

| Electromagnetic Induction | An AC-powered coil creates a changing magnetic field, inducing eddy currents in the workpiece. | Heat is generated internally, not applied externally. |

| Joule Heating | The induced eddy currents flow against the material's electrical resistance, creating friction and heat. | Provides rapid, precise, and efficient heating. |

Ready to harness the speed, precision, and purity of induction heating in your lab?

KINTEK specializes in high-performance lab equipment, including induction heating systems. Whether your focus is on high-volume manufacturing, material purity in a controlled atmosphere, or precise localized heat treatment, our solutions are designed to meet your specific laboratory needs.

Contact our experts today to discuss how our induction heating technology can enhance your processes and efficiency.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Lab-Scale Vacuum Induction Melting Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- What is the significance of applying mechanical pressure via a vacuum hot press? Maximize A356-SiCp Composite Density

- How does a vacuum hot press (VHP) contribute to the densification of Al-Cu-ZrC composite materials? Key VHP Benefits

- How does pressure control in vacuum hot press sintering equipment contribute to the densification of SiCp/6061 composites?

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?

- How does the degassing stage in a vacuum hot press (VHP) optimize diamond/aluminum composite performance?