At its core, MPCVD is a refined method for building materials one atom at a time. It stands for Microwave Plasma Chemical Vapor Deposition, a process that uses gaseous chemicals to grow a high-purity, solid film on a surface. Unlike traditional methods that rely solely on intense heat, MPCVD uses the focused energy of microwaves to create a plasma, enabling the deposition process to occur at significantly lower temperatures.

MPCVD solves a critical manufacturing challenge: how to deposit extremely high-quality crystalline materials, like synthetic diamonds, onto a surface without the damaging high heat required by conventional methods. It achieves this by using microwaves to create a highly reactive gas plasma that drives the chemical reaction.

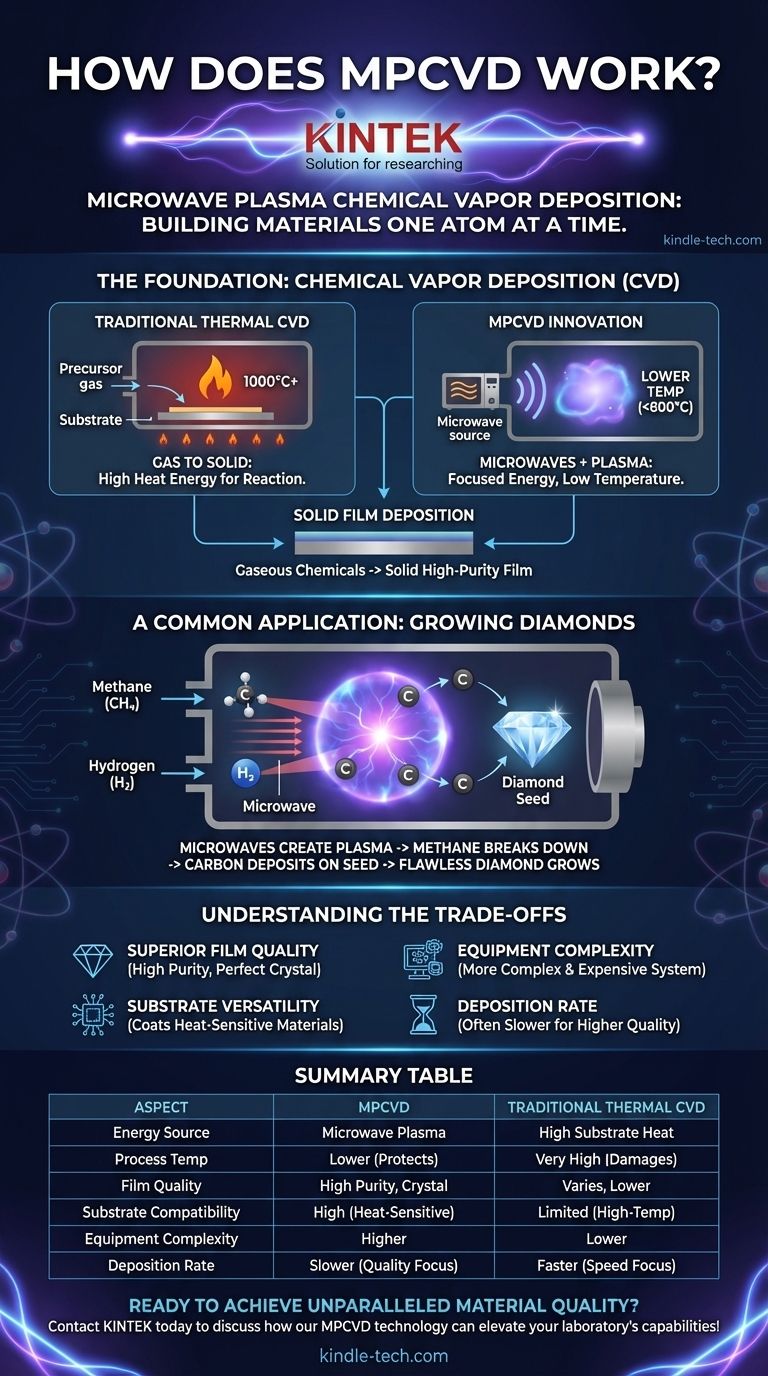

The Foundation: Understanding Chemical Vapor Deposition (CVD)

To understand MPCVD, we must first understand its parent process, Chemical Vapor Deposition (CVD). All CVD methods share the same fundamental goal.

The Core Principle: Gas to Solid

The basic principle of CVD is to transform a gas into a solid coating. This is done by introducing one or more volatile precursor gases into a chamber containing the object you want to coat, known as the substrate.

A chemical reaction is then triggered, causing the gases to decompose and deposit a thin, solid film onto the substrate's surface.

The Environment: The Reaction Chamber

This entire process takes place inside a sealed reaction chamber, which is typically held under a vacuum. The vacuum ensures purity and helps control the movement of the gases.

Any unwanted chemical by-products created during the reaction are safely vented out of the chamber, leaving only the desired solid film behind.

The Challenge: The Need for Energy

For the precursor gases to react and form a solid film, they need an energy boost. In traditional "thermal" CVD, this energy comes from heating the substrate to extremely high temperatures, often several hundred or even over a thousand degrees Celsius. This heat requirement is a significant limitation.

The Innovation: Adding Microwaves and Plasma (MPCVD)

MPCVD introduces a more sophisticated way to supply the necessary energy, which is what makes it a distinct and powerful process.

What is a Plasma?

Think of a plasma as the fourth state of matter, beyond solid, liquid, and gas. By adding immense energy to a gas, its atoms are broken apart into a highly energized "soup" of charged ions and electrons. This plasma state is extremely reactive.

The Role of Microwaves

In MPCVD, microwaves are beamed into the chamber. This microwave energy is absorbed by the precursor gases, "exciting" them and transforming them into a stable, glowing plasma. The microwaves are the engine that creates and sustains this reactive state.

The Key Advantage: Low-Temperature Deposition

Because the plasma itself is so reactive, the substrate does not need to be super-heated. The energy required for the deposition reaction comes from the energized particles within the plasma, not from the raw temperature of the substrate.

This allows for the growth of high-quality crystalline films at much lower temperatures, protecting heat-sensitive substrates from damage.

A Common Application: Growing Diamonds

MPCVD is the leading method for producing high-purity lab-grown diamonds. In this process, a small diamond "seed" is placed in the chamber. A mixture of methane gas (a source of carbon) and hydrogen is introduced.

Microwaves then turn the gas mixture into a plasma. Within this plasma, the methane molecules break apart, and carbon atoms deposit onto the diamond seed, growing a larger, flawless diamond layer by layer.

Understanding the Trade-offs

While powerful, MPCVD is a specialized tool with its own set of benefits and limitations.

The Benefit: Superior Film Quality

The controlled plasma environment allows for the growth of materials with exceptionally high purity and a perfect crystalline structure. This is critical for high-performance applications in optics, electronics, and tooling.

The Benefit: Substrate Versatility

Because the process runs at lower temperatures, MPCVD can be used to coat a wider range of materials, including some polymers or assembled electronic components that would be destroyed by the heat of traditional CVD.

The Limitation: Equipment Complexity

An MPCVD system is more complex and expensive than a simple thermal CVD reactor. It requires a microwave generator, a carefully designed chamber, and precise gas and pressure control systems.

The Limitation: Deposition Rate

In some cases, MPCVD may have a slower deposition rate compared to high-temperature alternatives. The trade-off is often between speed and the ultimate quality of the resulting film.

When is MPCVD the Right Process?

Choosing a deposition method depends entirely on the material you need and the substrate you are using.

- If your primary focus is creating exceptionally pure crystalline films (like diamond or graphene): MPCVD is the industry-standard choice due to its unparalleled control over material quality.

- If your primary focus is coating a heat-sensitive substrate: MPCVD's low-temperature operation makes it one of the few viable options for high-quality deposition without causing thermal damage.

- If your primary focus is simple, bulk coating on a durable material: A less complex and faster method, like thermal CVD or PVD, may be more cost-effective.

Ultimately, MPCVD represents a strategic choice for applications where material perfection and process control are more important than raw speed or equipment cost.

Summary Table:

| Aspect | MPCVD | Traditional Thermal CVD |

|---|---|---|

| Energy Source | Microwave-generated plasma | High substrate temperature |

| Process Temperature | Lower (protects substrates) | Very high (can damage substrates) |

| Film Quality | High purity, perfect crystalline structure | Varies, often lower quality |

| Substrate Compatibility | High (works with heat-sensitive materials) | Limited to high-temperature materials |

| Equipment Complexity | Higher (microwave generator, precise controls) | Lower |

| Deposition Rate | Slower (focus on quality) | Faster (focus on speed) |

Ready to achieve unparalleled material quality with MPCVD?

KINTEK specializes in advanced lab equipment, including MPCVD systems, to help you grow high-purity crystalline films like diamond and graphene with precision and control. Our expertise ensures you get the right solution for your research or production needs, protecting heat-sensitive substrates while delivering superior results.

Contact us today to discuss how our MPCVD technology can elevate your laboratory's capabilities!

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- How does a microwave plasma reactor facilitate the synthesis of diamond? Master MPCVD with Precision Technology

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What is MPCVD? Unlock Atom-by-Atom Precision for High-Purity Materials

- What are the primary advantages of the CVD method for growing diamonds? Engineering High-Purity Gems and Components

- What is the microwave plasma method? A Guide to High-Purity Material Synthesis