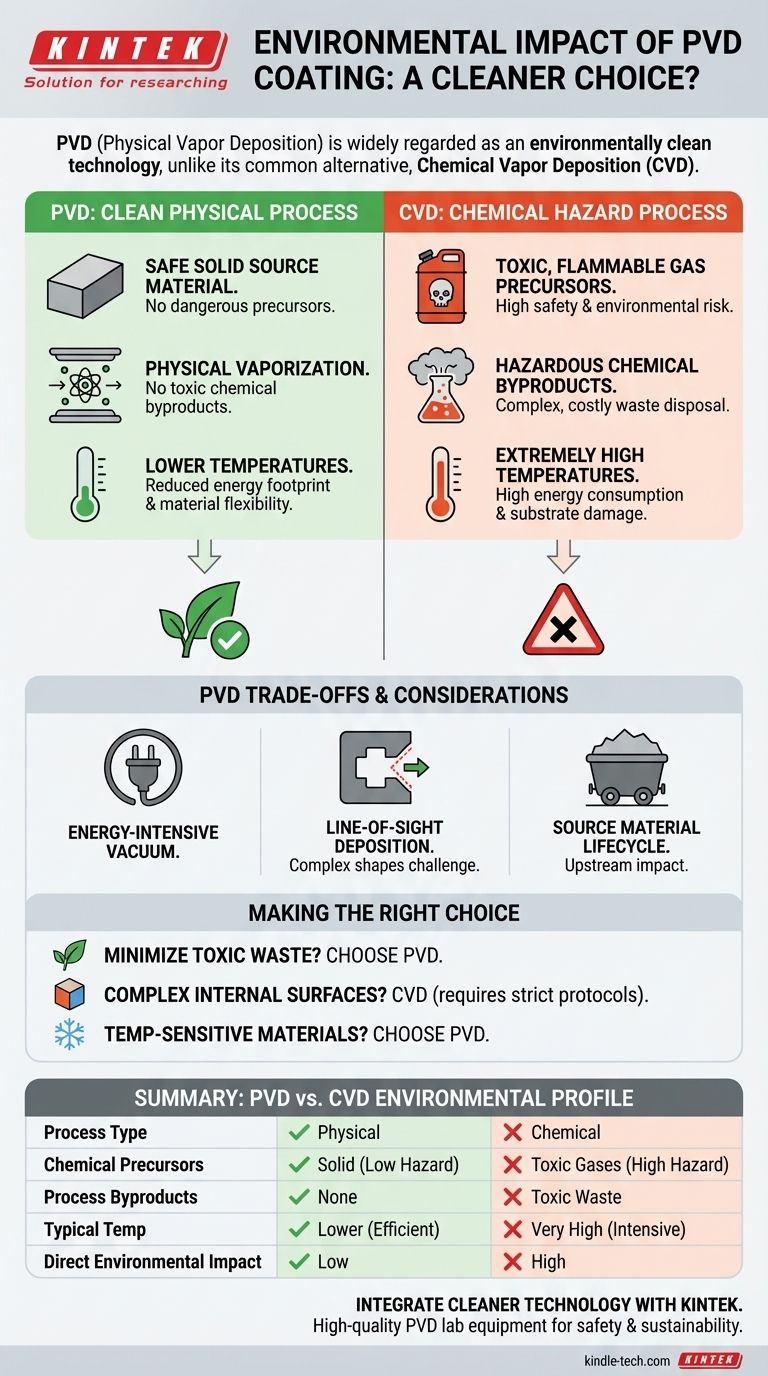

In short, Physical Vapor Deposition (PVD) is widely regarded as an environmentally clean coating technology. Unlike its common alternative, Chemical Vapor Deposition (CVD), PVD is a physical process that does not rely on hazardous chemical precursors or produce toxic chemical byproducts, making its direct environmental impact significantly lower.

The core difference is simple: PVD is a mechanical-like process that transfers a solid material in a vacuum, while CVD is a chemical process that creates a material from reactive gases, introducing toxicity risks that PVD avoids.

PVD vs. CVD: A Clear Environmental Distinction

To understand the environmental profile of PVD, it is most effective to compare it directly with the primary alternative, Chemical Vapor Deposition (CVD). The drawbacks of CVD clearly highlight the inherent advantages of PVD.

The Problem of Chemical Precursors

CVD processes require volatile chemical precursors to supply the coating material. These chemicals are often highly toxic, flammable, or pyrophoric (igniting spontaneously in air).

Handling, storing, and using these materials introduces significant safety and environmental risks that are not present in PVD. PVD uses a solid source material (like a metal target), which is physically vaporized, eliminating the need for dangerous precursor gases.

The Challenge of Hazardous Byproducts

The chemical reactions at the heart of CVD often produce toxic, corrosive, and environmentally harmful byproducts.

Neutralizing and disposing of this hazardous waste is a complex and costly problem. Because PVD is a physical process—essentially moving atoms from a source to a substrate—it does not create chemical reaction byproducts, thus avoiding this entire waste stream.

The Role of High Temperatures

Many CVD processes operate at extremely high temperatures. This high energy consumption has its own environmental footprint and can damage heat-sensitive substrates, limiting material choices.

While PVD also requires energy to create a vacuum and vaporize the source material, many PVD techniques (like sputtering) can be performed at much lower temperatures than typical CVD processes. This can reduce the overall energy footprint and expands the range of materials that can be safely coated.

Understanding the Trade-offs and Limitations

While PVD is environmentally favorable, no industrial process is without impact. Objectivity requires acknowledging its operational context and limitations.

Energy Consumption

Creating and maintaining the high vacuum required for PVD is energy-intensive. The equipment, including vacuum pumps and the power sources for vaporization (e.g., sputtering magnetrons or electron beams), consumes a significant amount of electricity.

Line-of-Sight Deposition

Most PVD processes are "line-of-sight," meaning they coat surfaces directly exposed to the vapor source. Coating complex, three-dimensional shapes with uniform thickness can be challenging and may require complex part rotation.

This is a process limitation, not a direct environmental one, but it can make CVD a necessary choice for certain applications despite its environmental drawbacks.

Source Material Lifecycle

The environmental impact of the source materials themselves should be considered. The mining, refining, and manufacturing of the solid targets used in PVD have their own upstream environmental footprint, though this is true for raw materials in nearly any manufacturing process.

Making the Right Choice for Your Application

Selecting a coating technology requires balancing performance needs with environmental responsibilities. PVD offers a compelling path for reducing direct chemical hazards.

- If your primary focus is minimizing toxic waste and chemical hazards: PVD is the superior choice, as it avoids the dangerous precursors and corrosive byproducts inherent to CVD.

- If you must coat a complex internal surface or 3D part with perfect uniformity: CVD may offer performance advantages, but you must be prepared to manage its significant environmental and safety protocols.

- If you are working with temperature-sensitive materials like polymers or certain alloys: Low-temperature PVD processes provide a viable and safer coating solution where high-temperature CVD would not be an option.

Ultimately, choosing PVD is often a decision to embrace a fundamentally cleaner and safer manufacturing process by design.

Summary Table:

| Aspect | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical (atom transfer) | Chemical (gas reactions) |

| Chemical Precursors | Solid targets (low hazard) | Toxic, flammable gases (high hazard) |

| Process Byproducts | None (no chemical reactions) | Toxic, corrosive waste gases |

| Typical Process Temperature | Lower temperatures (energy efficient for many substrates) | Very high temperatures (energy intensive) |

| Direct Environmental Impact | Low (no toxic chemical handling or waste) | High (requires hazardous material management) |

Ready to integrate cleaner, safer coating technology into your laboratory workflow?

At KINTEK, we specialize in providing high-quality PVD lab equipment and consumables that help you achieve superior coatings while minimizing environmental impact. Our solutions are designed for laboratories that prioritize safety and sustainability without compromising on performance.

Contact our experts today to find the ideal PVD system for your specific application and take a step towards greener manufacturing.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is the function of tungsten filaments in HFCVD? Powering Diamond Film Synthesis with Thermal Excitation

- Can polymers be deposited using CVD processes? A Guide to Solvent-Free, Conformal Polymer Films

- What is the chemical vapor deposition of silicon carbide? A Guide to High-Performance SiC Manufacturing

- Which is better CVD or Hpht? Choose the Right Lab-Grown Diamond for Your Needs

- Why is physical vapor deposition conducted in a high vacuum? To Ensure Purity and Performance

- What are the benefits of LPCVD? Achieve Superior Uniformity and High-Throughput Thin Films

- What is the principle of sputtering process? A Guide to Thin Film Deposition

- What does the sputtering rate depend on? Master the Key Factors for Thin Film Deposition Speed