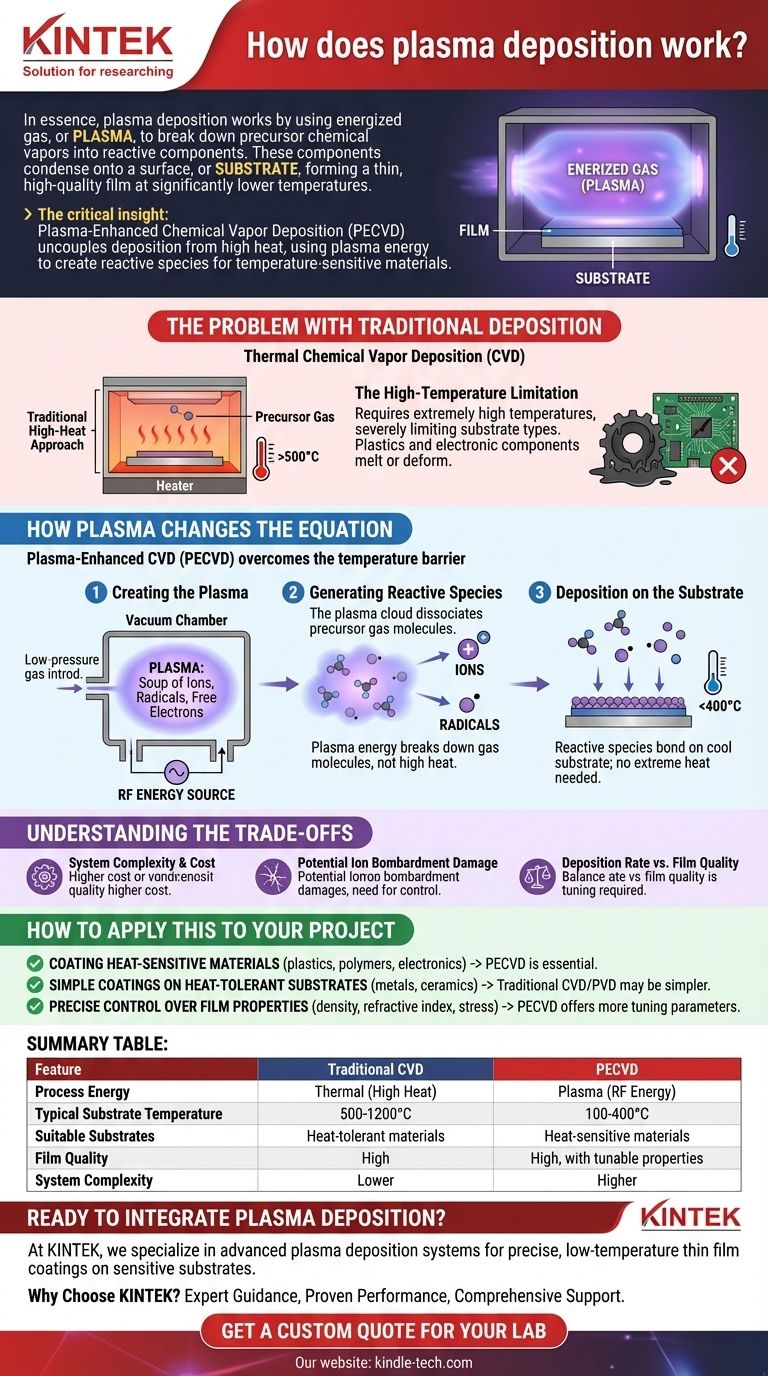

In essence, plasma deposition works by using an energized gas, or plasma, to break down precursor chemical vapors into reactive components. These components then condense onto a surface, or substrate, forming a thin, high-quality film at significantly lower temperatures than required by conventional deposition methods.

The critical insight is that plasma deposition, specifically Plasma-Enhanced Chemical Vapor Deposition (PECVD), uncouples the deposition process from high heat. By using plasma energy instead of thermal energy, it creates highly reactive chemical species that can form films on temperature-sensitive materials that would otherwise be damaged or destroyed.

The Problem With Traditional Deposition

To understand the value of plasma, we must first look at its predecessor: thermal Chemical Vapor Deposition (CVD).

The Traditional High-Heat Approach

In standard CVD, a precursor gas containing the atoms you want to deposit is passed over a heated substrate.

The intense heat provides the thermal energy needed to break the chemical bonds in the gas, allowing the desired atoms to settle and form a film on the substrate surface.

The High-Temperature Limitation

The primary drawback of thermal CVD is the requirement for extremely high temperatures, often many hundreds or even over a thousand degrees Celsius.

This heat requirement severely limits the types of materials that can be used as a substrate. Plastics, many electronic components, and other polymers would simply melt, deform, or be destroyed, making them incompatible with this process.

How Plasma Changes the Equation

Plasma-Enhanced CVD (PECVD) was developed specifically to overcome this temperature barrier. It introduces a new form of energy into the system.

Step 1: Creating the Plasma

Inside a vacuum chamber, a low-pressure precursor gas is introduced. An energy source, typically a radio frequency (RF) electrical field, is then applied to this gas.

This energy strips electrons from the gas atoms, creating a "soup" of free electrons, positively charged ions, and neutral but highly reactive particles known as radicals. This energized, ionized gas is the plasma.

Step 2: Generating Reactive Species

It is the energy of the plasma itself—not high heat—that breaks down the precursor gas molecules.

This dissociation creates the chemically aggressive ions and radicals needed for the deposition reaction. These species are chemically "eager" to bond and form a stable solid film.

Step 3: Deposition on the Substrate

These reactive species then travel to and bombard the comparatively cool substrate surface. Upon arrival, they react, bond together, and build up layer by layer into a dense, uniform thin film.

Because the activation energy was provided by the plasma, the substrate does not need to be heated to extreme temperatures for the film to form effectively.

Understanding the Trade-offs

While powerful, PECVD is not a universal solution. It involves a clear set of engineering trade-offs.

System Complexity and Cost

PECVD systems are inherently more complex than thermal CVD furnaces. They require sophisticated vacuum chambers, high-power RF generators, and precise gas control systems, which increases both initial cost and maintenance complexity.

Potential for Ion Bombardment Damage

The same high-energy ions that enable low-temperature deposition can, if not carefully controlled, cause minor structural damage to the substrate's surface lattice. This is a critical parameter that must be managed for sensitive applications like semiconductor manufacturing.

Deposition Rate vs. Film Quality

Engineers must often balance deposition speed with the quality of the resulting film. Increasing plasma power can speed up the process, but it can also lead to higher internal stress within the film or reduced uniformity across the substrate.

How to Apply This to Your Project

Your choice between plasma deposition and other methods depends entirely on your material constraints and performance goals.

- If your primary focus is coating heat-sensitive materials (like plastics, polymers, or finished electronic devices): PECVD is the essential and often only viable technology.

- If your primary focus is achieving simple, robust coatings on heat-tolerant substrates (like metals or ceramics): Traditional thermal CVD or physical vapor deposition (PVD) may be a simpler and more cost-effective solution.

- If your primary focus is precise control over film properties (like density, refractive index, or internal stress): PECVD provides more tuning parameters (power, pressure, gas flow) to achieve highly specific material characteristics.

Ultimately, plasma deposition is a foundational technology that enables the creation of advanced materials critical to modern electronics, optics, and medical devices.

Summary Table:

| Feature | Traditional CVD | Plasma-Enhanced CVD (PECVD) |

|---|---|---|

| Process Energy | Thermal (High Heat) | Plasma (RF Energy) |

| Typical Substrate Temperature | 500-1200°C | 100-400°C |

| Suitable Substrates | Heat-tolerant materials (metals, ceramics) | Heat-sensitive materials (plastics, polymers, electronics) |

| Film Quality | High | High, with tunable properties |

| System Complexity | Lower | Higher (vacuum, RF generators required) |

Ready to Integrate Plasma Deposition into Your Lab Workflow?

At KINTEK, we specialize in providing advanced lab equipment and consumables for cutting-edge research and manufacturing. Our plasma deposition systems are engineered to deliver precise, low-temperature thin film coatings for your most sensitive substrates.

Why Choose KINTEK for Your Plasma Deposition Needs?

- Expert Guidance: Our team helps you select the right PECVD system for your specific material and application requirements.

- Proven Performance: Achieve uniform, high-quality films on plastics, polymers, and electronic components without thermal damage.

- Comprehensive Support: From installation to maintenance, we ensure your lab operates at peak efficiency.

Contact us today to discuss how our plasma deposition solutions can advance your research or production capabilities. Let's engineer the perfect thin film solution for your temperature-sensitive materials.

Get a Custom Quote for Your Lab

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What is the effect of temperature on PECVD? Optimize Film Quality vs. Substrate Safety

- What is the advantage of VHF-PECVD over RF-PECVD? Maximize Deposition Rates for Advanced Thin Film Growth

- What is plasma chemical vapor deposition? A Low-Temperature Thin Film Coating Solution

- What temperature is DLC applied? Achieve Superior Coatings Without Compromising Substrate Integrity

- What is PECVD in a solar cell? The Key to High-Efficiency Solar Manufacturing

- Can you put DLC on aluminum? Yes, with the right multi-layer coating process.

- How does the PECVD process utilize plasma to deposit thin films? Achieve High-Quality Coatings at Low Temperatures