In short, pyrolysis works without oxygen to prevent burning. Instead of combusting into ash and heat, the material is forced to undergo thermal decomposition. The intense heat breaks down its complex molecular structure into simpler, often more valuable, components like gases, liquids (bio-oil), and a solid carbon-rich residue (biochar).

The absence of oxygen is the defining factor that separates pyrolysis from combustion. It transforms a destructive burning process into a controlled decomposition, allowing us to harvest valuable chemical products from a raw material rather than simply releasing its energy as heat.

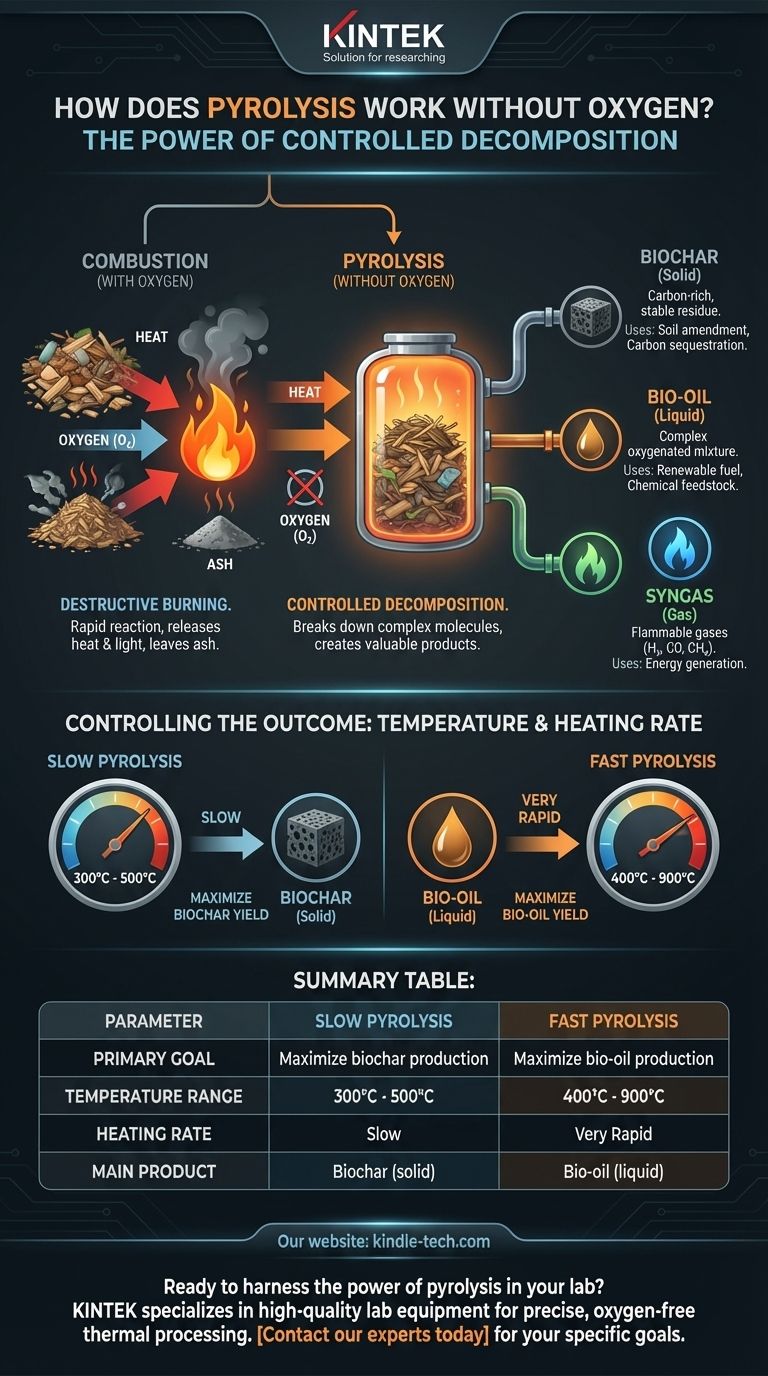

The Core Principle: Decomposition vs. Combustion

To truly understand pyrolysis, you must first distinguish it from the process we are all familiar with: burning, or combustion. The presence or absence of oxygen is the only thing separating the two.

The Role of Oxygen in Combustion

Combustion is a rapid chemical reaction between a substance and an oxidant, almost always oxygen. When you burn wood, the heat breaks down the wood fiber, and the resulting molecules immediately and violently react with oxygen in the air.

This oxidation reaction releases a large amount of energy as heat and light. The original material is almost entirely consumed, leaving behind ash.

How Thermal Decomposition Works

Pyrolysis is a different chemical pathway. By heating material in a sealed, oxygen-free environment, you prevent the oxidation reaction from ever starting.

Without oxygen to react with, the heat energy directly attacks the chemical bonds holding the material's molecules together. Large, complex organic polymers like cellulose and lignin are cracked and broken apart into smaller, simpler molecules.

The Three Primary Products

This controlled decomposition reliably sorts the original material into three distinct product streams:

- Biochar: A stable, solid residue that is rich in carbon.

- Bio-oil: A complex liquid mixture of oxygenated hydrocarbons.

- Syngas: A mix of flammable gases, primarily hydrogen, carbon monoxide, and methane.

Controlling the Outcome

The specific products of pyrolysis are not left to chance. The process parameters, primarily temperature and heating rate, act as precise control levers.

Why Temperature is the Critical Lever

The process is typically conducted between 300°C and 900°C. Different chemical bonds break at different temperatures, allowing operators to target specific outputs.

Slow Pyrolysis for Biochar

Lower temperatures and slower heating rates (slow pyrolysis) favor the production of the solid component. This maximizes the yield of biochar, which is highly valued for carbon sequestration and soil amendment.

Fast Pyrolysis for Bio-Oil

Conversely, very high temperatures and rapid heating rates (fast pyrolysis) are used to maximize the liquid fraction. This process cracks molecules quickly, preventing them from repolymerizing into char and instead yielding bio-oil, a potential renewable fuel source.

Understanding the Benefits and Challenges

Choosing pyrolysis over combustion is a strategic decision based on desired outcomes and an understanding of the inherent trade-offs.

Benefit: Creating Value, Not Just Heat

The primary advantage of pyrolysis is its ability to convert low-value feedstocks, like biomass or waste plastic, into higher-value products. It is a tool for material transformation, whereas combustion is a tool for immediate energy release.

Benefit: Environmental Control

By preventing combustion, pyrolysis avoids the creation of many harmful byproducts. The controlled, oxygen-starved environment significantly reduces pollutants and prevents the formation of toxic compounds like dioxins and furans, which can be formed during incomplete burning.

Challenge: Process Complexity

The main trade-off is complexity. Maintaining an oxygen-free, high-temperature environment requires a purpose-built reactor and careful process control. It is a more sophisticated and capital-intensive technology than a simple incinerator or furnace.

Making the Right Choice for Your Goal

The decision to use pyrolysis is fundamentally about your objective.

- If your primary focus is soil amendment or carbon sequestration: Slow pyrolysis is the correct path to maximize the yield of stable biochar.

- If your primary focus is producing a renewable liquid fuel or chemical feedstock: Fast pyrolysis is the optimal choice to generate the highest possible volume of bio-oil.

- If your primary focus is simply waste volume reduction with energy recovery: Combustion is often a simpler path, but pyrolysis offers the flexibility of creating storable fuels (gas and oil) instead of just immediate heat.

By removing oxygen from the equation, pyrolysis transforms a simple act of heating into a precise tool for chemical conversion.

Summary Table:

| Parameter | Slow Pyrolysis | Fast Pyrolysis |

|---|---|---|

| Primary Goal | Maximize biochar production | Maximize bio-oil production |

| Temperature Range | 300°C - 500°C | 400°C - 900°C |

| Heating Rate | Slow | Very Rapid |

| Main Product | Biochar (solid) | Bio-oil (liquid) |

Ready to harness the power of pyrolysis in your lab? KINTEK specializes in high-quality lab equipment for thermal processing and material transformation. Whether you're researching biochar for soil science or bio-oil for renewable fuels, our reactors and furnaces provide the precise, oxygen-free environment you need. Contact our experts today to find the perfect pyrolysis solution for your laboratory's specific goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs