In short, temperature is the engine of the entire process. Chemical Vapor Deposition (CVD) relies on a heated substrate to provide the necessary thermal energy to initiate and sustain the chemical reactions. Without sufficient heat on the target surface, the precursor gases will not decompose or react, and no coating will form.

The core function of temperature in CVD is to supply the activation energy required to break chemical bonds in the precursor gases. This allows them to react on the hot workpiece surface, forming a new, stable solid film.

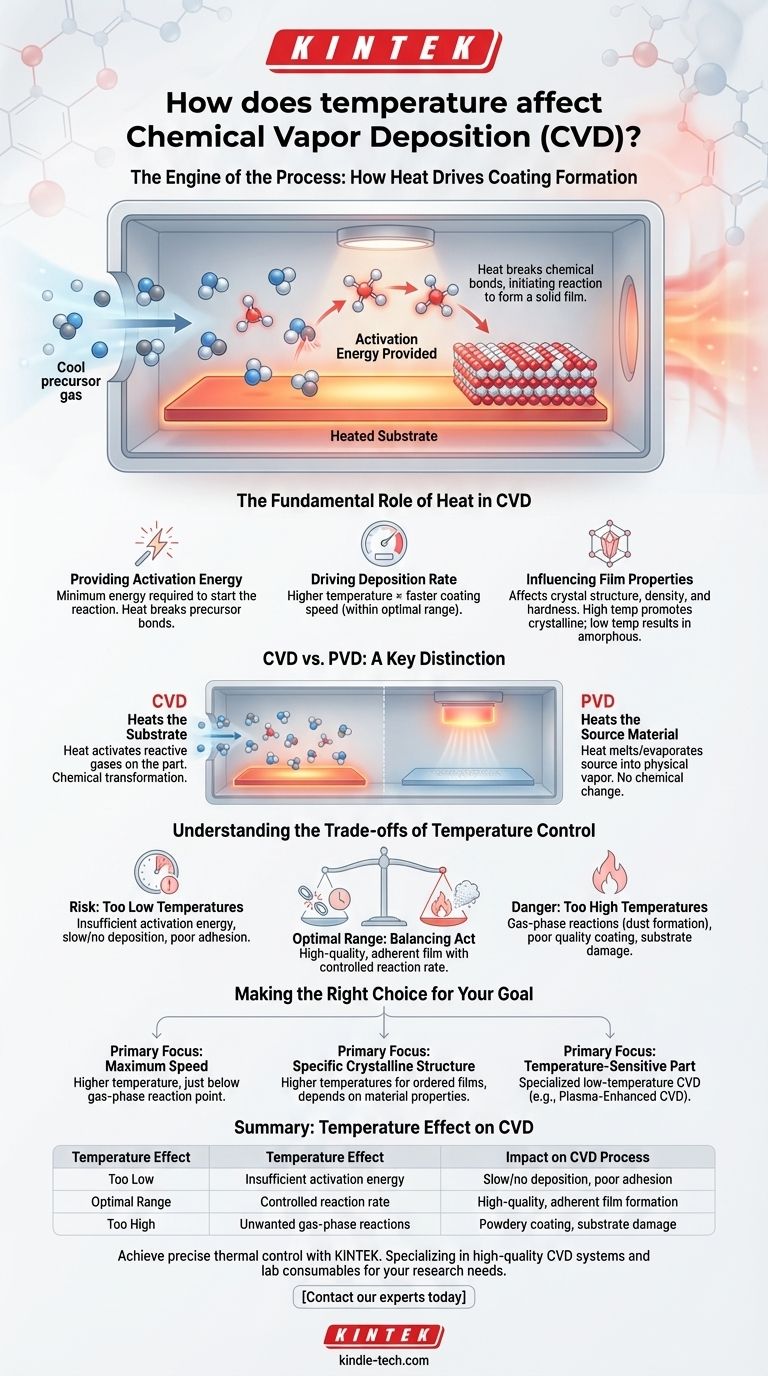

The Fundamental Role of Heat in CVD

To understand CVD, you must see it as a controlled chemical reaction occurring on a surface. Like most chemical reactions, it is governed by energy and kinetics, with temperature being the primary control lever.

Providing Activation Energy

Every chemical reaction requires a minimum amount of energy to get started, known as activation energy. In CVD, the heat applied to the substrate provides this energy.

When the gaseous molecules (precursors) come into contact with the hot surface, they absorb thermal energy. This energy causes their internal chemical bonds to break, creating reactive species that can then form a new solid material.

Driving Deposition Rate

The temperature directly controls the speed, or deposition rate, of the coating process.

Within a certain range, a higher temperature increases the rate of reaction on the surface, leading to a thicker film in less time. However, this relationship is not infinite; an optimal temperature range exists for each specific process.

Influencing Film Properties

The final characteristics of the coating—such as its crystal structure, density, and hardness—are highly dependent on the deposition temperature.

Higher temperatures often provide atoms with more energy to move around on the surface before settling into place. This can promote the formation of a more ordered, crystalline structure, whereas lower temperatures might result in a disordered, amorphous film.

CVD vs. PVD: A Key Distinction in Temperature's Role

It is critical to distinguish how temperature is used in CVD versus its primary alternative, Physical Vapor Deposition (PVD). This distinction clarifies the unique function of heat in the CVD process.

CVD Heats the Substrate to Cause a Reaction

In CVD, the key thermal component is the hot substrate. The process introduces relatively cool reactive gases into a chamber where they are activated by the heat of the part being coated. The chemical nature of the molecules is transformed.

PVD Heats the Source Material to Create a Vapor

In PVD, the heat is applied to the source material (the coating material itself) to turn it into a vapor through melting and evaporation. This vapor then physically travels and condenses on the (often cooler) substrate. The material's chemical nature does not change.

Understanding the Trade-offs of Temperature Control

Controlling the temperature in a CVD process is a balancing act. Deviating from the optimal range can lead to significant problems with process efficiency and the quality of the final product.

The Risk of Too Low Temperatures

If the temperature is too low, the precursor gases will not have enough activation energy to react effectively. This results in an extremely slow or nonexistent deposition rate and can cause poor adhesion of the film to the substrate.

The Danger of Too High Temperatures

Excessively high temperatures can be even more detrimental. They can cause the precursor gases to react in the gas phase before reaching the substrate, forming tiny particles that result in a weak, powdery, and non-adherent coating. High heat can also damage the substrate itself, especially for sensitive electronics or materials with low melting points.

Thermal Budget Constraints

Many applications, particularly in semiconductor manufacturing, have a strict "thermal budget." This means the substrate can only be exposed to a certain maximum temperature for a limited time before its existing components are damaged. The CVD process temperature must be carefully chosen to stay within this budget.

Making the Right Choice for Your Goal

The optimal temperature for a CVD process is not a single value; it is determined entirely by the desired outcome and the constraints of the substrate material.

- If your primary focus is maximum deposition speed: You will need to operate at a higher temperature, carefully tuned to be just below the point where unwanted gas-phase reactions begin to occur.

- If your primary focus is a specific crystalline structure: The required temperature is dictated by the material's properties; creating highly ordered crystalline films generally requires higher temperatures to give atoms sufficient mobility.

- If your primary focus is coating a temperature-sensitive part: You must use specialized low-temperature CVD processes (like Plasma-Enhanced CVD) where energy is supplied by an electrical plasma rather than solely by heat.

Ultimately, mastering temperature control is essential to mastering the Chemical Vapor Deposition process and achieving a high-quality, functional coating.

Summary Table:

| Temperature Effect | Impact on CVD Process |

|---|---|

| Too Low | Insufficient activation energy; slow/no deposition, poor adhesion. |

| Optimal Range | Controlled reaction rate; high-quality, adherent film formation. |

| Too High | Unwanted gas-phase reactions; powdery coating, substrate damage. |

Achieve precise thermal control for your CVD processes with KINTEK.

Whether you are developing advanced semiconductors, durable tool coatings, or specialized thin films, the right lab equipment is critical. KINTEK specializes in high-quality CVD systems and lab consumables designed to deliver the exact temperature control your research and production demand.

Let us help you optimize your deposition process. Contact our experts today to discuss your specific application needs and discover the KINTEK solution for you.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques