At its core, a vacuum pump does not "suck" air out of a system in the way a straw pulls liquid. Instead, it functions by mechanically capturing and removing gas molecules from a sealed space. This removal creates a low-pressure region, and physics dictates that gas from the higher-pressure system will naturally flow into this new, lower-pressure area to equalize the pressure.

A vacuum pump works by creating a pressure differential. It is fundamentally a gas transfer device, pushing molecules from a sealed system to the outside atmosphere, which causes the pressure inside the system to drop.

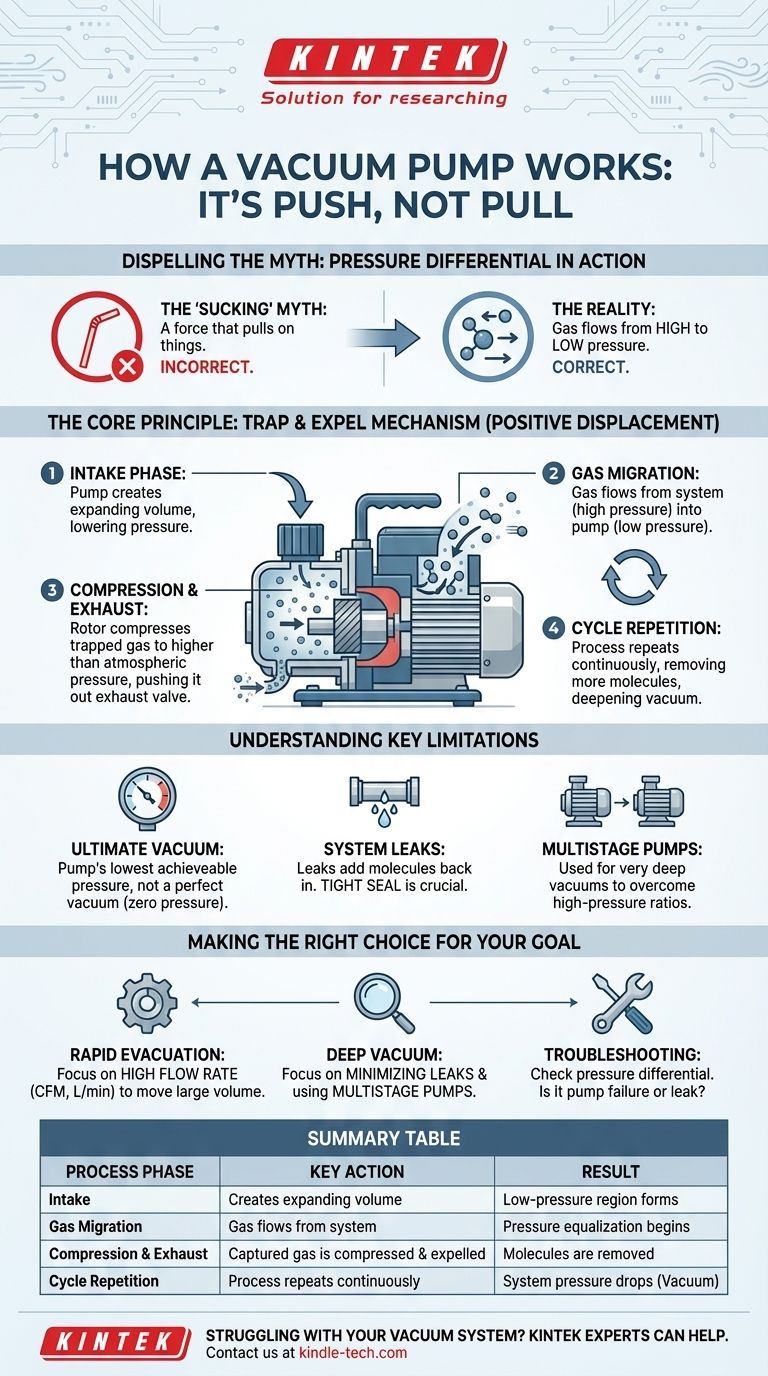

The Core Principle: It's Push, Not Pull

A common misunderstanding is that a vacuum is a force that actively pulls on things. The reality is based on the natural behavior of gases.

Dispelling the "Sucking" Myth

A vacuum is not a force; it is the absence of pressure. What we perceive as "suction" is actually the higher pressure of the surrounding atmosphere pushing into the low-pressure space. A vacuum pump's job is to create that low-pressure space.

Creating a Pressure Differential

Gas molecules are in constant, random motion and naturally spread out to fill any available volume. They will always move from an area of higher concentration (high pressure) to an area of lower concentration (low pressure) until equilibrium is reached. The vacuum pump leverages this fundamental principle.

The Mechanical Action: Trap and Expel

Most vacuum pumps operate on a positive displacement principle. A rotating mechanism (like a rotor or vanes) inside the pump chamber creates an expanding space connected to the system you want to evacuate. This expansion lowers the pressure, and gas flows in. The mechanism then seals off that pocket of gas, compresses it, and forcibly expels it through an exhaust valve.

The Pump's Cycle in Action

This "trap and expel" process happens in a continuous cycle, with each cycle removing more gas molecules from the system.

Step 1: The Intake Phase

The pump's internal mechanism, such as an eccentric rotor, creates an expanding volume inside the compression chamber. This expansion is what generates the low-pressure region connected to the system via the pump's inlet.

Step 2: Gas Migration

Because the pressure inside the pump's chamber is now lower than the pressure in the connected system, gas molecules from the system flow into the chamber to equalize the pressure.

Step 3: The Compression & Exhaust Phase

The rotor continues its turn, isolating the captured volume of gas from the inlet. It then compresses this gas, increasing its pressure to be higher than the outside atmospheric pressure. This allows a one-way exhaust valve to open and push the captured gas out of the pump.

Step 4: Repetition and Deeper Vacuum

This cycle repeats thousands of times per minute. With each cycle, more molecules are removed from the system, progressively lowering its internal pressure and creating a deeper vacuum.

Understanding the Key Limitations

The effectiveness of this process is not infinite. Understanding the limitations is critical for proper application and troubleshooting.

The Concept of Ultimate Vacuum

A pump cannot create a perfect vacuum (zero pressure) because it can never remove 100% of the gas molecules. The ultimate vacuum is the lowest pressure a pump can achieve, limited by its design efficiency and tiny internal leaks.

Why System Leaks Are Critical

A vacuum pump is trying to remove molecules, while a leak is adding them back in. If the leak rate is equal to the pump's removal rate, the vacuum level will stagnate. This is why ensuring a tight, leak-free seal on your system is often more important than the pump's power itself.

The Need for High-Pressure Ratios

As the vacuum gets deeper, there are far fewer molecules to remove from the system. Expelling these few molecules against the full force of atmospheric pressure becomes very difficult. This challenge is described by the pump's pressure ratio. To achieve very deep vacuums, multistage pumps are used, where one pump stage exhausts into the inlet of a second stage, making the process more efficient.

Making the Right Choice for Your Goal

Understanding this principle helps you diagnose problems and select the right approach for your task.

- If your primary focus is achieving a deep vacuum: Your main concern is eliminating all leaks and potentially using a multistage pump. You are fighting a battle of removing the last few molecules faster than they can leak back into the system.

- If your primary focus is rapid evacuation of a large volume: You need a pump with a high flow rate (measured in CFM or L/min), as your initial challenge is moving a massive number of molecules quickly.

- If you are troubleshooting a poor vacuum: Think in terms of the pressure differential. The issue is either the pump failing to create a low-pressure zone (mechanical failure) or, more commonly, a leak is preventing the system's pressure from dropping (seal failure).

By viewing the vacuum effect as a process of moving gas, you gain a powerful mental model for operating and troubleshooting any vacuum system effectively.

Summary Table:

| Process Phase | Key Action | Result |

|---|---|---|

| Intake | Pump creates an expanding volume. | Low-pressure region forms. |

| Gas Migration | Gas flows from system (high pressure) to pump (low pressure). | Pressure equalization begins. |

| Compression & Exhaust | Captured gas is compressed and expelled. | Molecules are removed from the system. |

| Cycle Repetition | Process repeats continuously. | System pressure drops, creating a vacuum. |

Struggling to achieve the right vacuum for your application? Understanding the core principle of gas transfer is the first step to optimizing your process. The experts at KINTEK specialize in lab equipment, including vacuum systems and pumps, to meet your specific laboratory needs. We can help you select the right pump, diagnose performance issues, and ensure your system operates at peak efficiency. Contact us today to discuss your vacuum requirements and let our expertise work for you. Get in touch via our contact form

Visual Guide

Related Products

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Why is a forced-air drying oven used at 120 °C for molybdenum catalysts? Preserve Your Catalyst’s Pore Structure

- What are the uses of desiccators and specific thermal regulators? Expert Insights for Vapor-Assisted Conversion

- Why are zirconia grinding jars and balls preferred for recycled graphite? Optimize Purity and Efficiency

- What are the different types of temperature sensors? Choose the Right Sensor for Your Application

- What is the working principle of laboratory furnace? From Electricity to Precision Heat

- What is the function of a laboratory magnetic stirrer? Enhance Yield & Uniformity in Thermal Extraction

- What is the function of a magnetic stirring hot plate in zirconia-alumina synthesis? Master Solution Combustion Prep

- How does an automatic PID temperature controller ensure data accuracy? Achieve Precision in Propane Oxidation